Minarik 200-0416 User manual

4Q Isolation Adder Card

for RGx00 Series Drives

14300 De La Tour Drive • South Beloit, IL 61080

Phone: (815) 624-2745 • Fax: (815) 624-6334

www.minarikdrives.com

200-0416

An American Control Electronics Brand

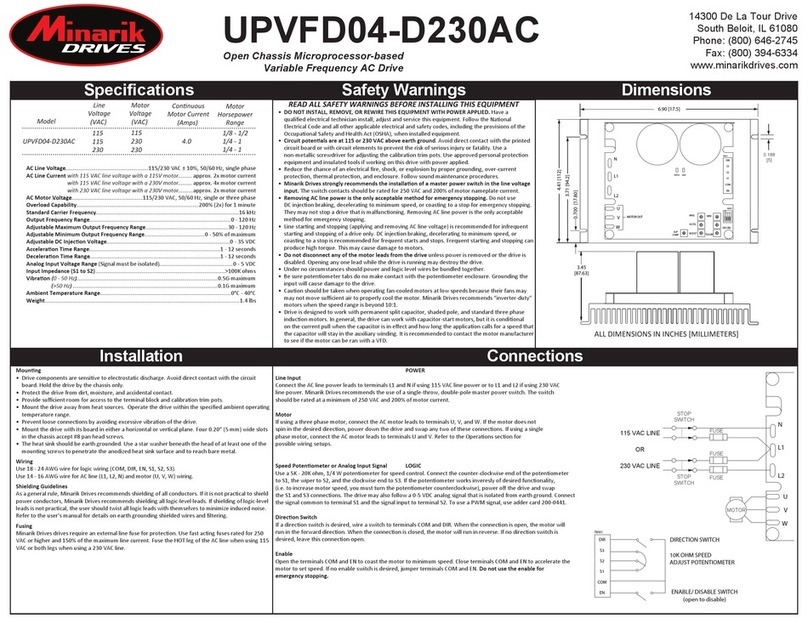

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Dimensions

L1 L2

230V

L2

115V GND F1 F2 A2 A1

SW501

C504

TB501

C503

C505

TB502

IC502

IC501

C502

115 230 230 115

SW502

L1 L2

FU502FU501

FAST ACTING

FUSES ONLY

S3 S2 S1 S0 RB1 RB2 -15 +15 T1 T2

T505

SCR501

MIN SPD FWD TQ REV TQ IR COMP MAX SPD FWD ACC REV ACC DB TACH

0.19 [5]

8.90 [226]

8.40 [213]

3.50 [89]

4.78 [121]

INH

COMPOL REVTPINPUT 2INPUT1COM+15-15L2L1OUT 2OUT1

115 230

INPUT VOLTAGE SELECT

T501

SIGNAL

INPUT

ADJUST

SW501

R501

IC505

1-5mA

4-20mA

10-50mA

P502

P503

MAX

OUT

MIN

OUT

C501

C502

C503

C504

IC501

IC502

IC503

IC504 123

P501

SW502

C506 C505 C508 C507

3.07 [78]

1.85 [47]

0.92 [23]

Step 1: Remove the 2 SCR screws and the 2 hex nuts on the base RGx00 unit.

Step 2: Remove the 2 PC board screws to the le and right of the calibraon trim pots on the base

RGx00 unit.

Step 3: Fasten the braket to the chassis using the SCR screws. The bracket’s short standoffs replace

the two hex nuts removed in step 1. Screw in the 1.75 inch standoffs to the regenerave drive PC

board.

Step 4: Mount the PCM board above the bracket and 1.75 inch standoffs. Secure the PCM board with

four PC board screws; two unscrewed from the regenerave drive PC board in Step 2 and two included

in the PCM board hardware kit.

INHIBIT

SO501

SO502

T501

R501

C501

SCR502 SCR503 SCR504

T502

T503

SCR505 SCR506

R504 R505 R506

T504

SCR507 SCR508

C509

C508

C507

C506

C510

SW504SW503

ARMATURE FEEDBACK

90 180 ARM TACH

R502 R503

MIN SPD FWD TQ REV TQ IR COMP MAX SPD FWD ACC REV ACC DB TACH

P501 P502 P503 P504 P505 P506 P507 P508 P509

SCR SCREWS

HEX NUTS

UN

INHIBIT

SO501

SO502

T501

R501

C501

SCR502 SCR503

T502

T503

T504

C507

C506

C510

SW504SW503

ARMATURE FEEDBACK

90 180 ARM TACH

R502 R503

MIN SPD FWD TQ REV TQ IR COMP MAX SPD FWD ACC REV ACC DB TACH

P501 P502 P503 P504 P505 P506 P507 P508 P509

UN

508

509

PC BOARD SCREWS 1.75 INCH STANDOFFS

BRACKET

MIN SPD FWD TQ REV TQ IR COMP MAX SPD FWD ACC REV ACC DB TACH

PC BOARD SCREWS

PC BOARD SCREWS

COMPOL REVTPINPUT 2INPUT 1COM+15-15L2L1OUT 2OUT 1

115 230

INPUT VOLTAGE SELECT

T501

SIGNAL

INPUT

ADJUST

SW501

R501

IC505

1-5mA

4-20mA

10-50mA

P502

P503

MAX

OUT

MIN

OUT

C501

C502

C503

C504

IC501

IC502

IC503

IC504 123

P501

SW502

C506 C505 C508 C507

Installation

Safety Warnings

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH POWER APPLIED. Have a

• qualified electrical technician install, adjust and service this equipment. Follow the Naonal

• Electrical Code and all other applicable electrical and safety codes, including the provisions of the

• Occupaonal Safety and Health Act (OSHA), when installing equipment.

• Circuit potenals are at 115 or 230 VAC above earth ground. Avoid direct contact with the printed

• circuit board or with circuit elements to prevent the risk of serious injury or fatality. Use a non-

• metallic screwdriver for adjusng the calibraon trim pots. Use approved personal protecon

• equipment and insulated tools if working on this drive with power applied.

• Reduce the chance of an electrical fire, shock, or explosion by using proper grounding techniques,

•over-current protecon, thermal protecon, and enclosure. Follow sound maintenance procedures.

• Minarik Drives strongly recommends the installaon of a master power switch in the line voltage

•input. The switch contacts should be rated for 250 VAC and 200% of motor nameplate current.

• Removing AC line power is the only acceptable method for emergency stopping. Do not use

• regenerave braking, decelerang to minimum speed, or coasng to a stop for emergency stopping.

• They may not stop a drive that is malfunconing. Removing AC line power is the only acceptable

• method for emergency stopping.

• Line starng and stopping (applying and removing AC line voltage) is recommended for infrequent

• starng and stopping of a drive only. Regenerave braking, decelerang to minimum speed, or

•coasng to a stop is recommended for frequent starts and stops. Frequent starng and stopping can

• produce high torque. This may cause damage to motors.

• Do not disconnect any of the motor leads from the drive unless power is removed or the drive is

• disabled. Opening any one lead while the drive is running may destroy the drive.

• Under no circumstances should power and logic level wires be bundled together.

• Be sure potenometer tabs do no make contact with the potenometer’s body. Grounding the

• input will cause damage to the drive.

READ ALL SAFETY WARNINGS BEFORE INSTALLING THIS EQUIPMENT

Specifications

......................................................115/230 VAC ± 10%, 50/60 Hz, single phase

...............................................................................-25 to 25 VDC

...............................................................................-250 to 250 VDC

.................................................................................1-5 mA, 4-20 mA, 10-50 mA

............................................................................................................>25K ohms

..................................................................................................1K ohms

..............................................................................................235 ohms

............................................................................................100 ohms

.......................................................................................................-10 to 10 VDC

.............................................................................................................................0.01%

Power Requirements

AC Line Voltage

Input Signal Ranges

Voltage Signal, Narrow Range

Voltage Signal, Wide Range

Current Signal

Input Impedance

Voltage Signal

Current Signal, 1-5 mA

Current Signal, 4-20 mA

Current Signal, 10-50 mA

Output

Voltage Range

Linearity

250-0270 rev 1

No part of this document may be reproduced or retransmied in any form without wrien permission

from American Control Electronics. The informaon and technical data in this document are

subject to change without noce. American Control Electronics makes no warranty of any kind

with respect to this material, including, but not limited to, the implied warranes of its

merchantability and fitness for a given purpose. American Control Electronics assumes no

responsibility for any errors that may appear in this document and makes no commitment to

update or to keep current the informaon in this document.

AC Line: Connect the 115 or 230 VAC line to terminals 3 (L1) and 4 (L2).

Output Signal: Connect terminal 1 (OUT 1) to terminal S0 on the base unit.

Connect terminal 2 (OUT 2) to terminal S2 on the base unit.

Input Signal: Connect the signal common (-) to terminal 7 (COM). If using an analog voltage range

greater than 25 VDC, connect the signal reference (+) to terminal 9 (INPUT 2). Otherwise, connect

the signal reference (+) to terminal 8 (INPUT 1).

Direcon Switch: Connect a SPST switch to terminals COM and POL REV. Close the switch to change

motor rotaon direcon. Open the switch to change the motor rotaon back to it’s inial direcon.

Terminals +15 and -15 are used to power potenometers or other devices as needed.

Terminal TP is used during the calibraon procedure.

Calibration

The following minimum and maximum values should be known.

INmin - Minimum analog input signal.

INmax - Maximum analog input signal.

OUTmin - Minimum analog output signal.

OUTmax - Maximum analog output signal.

INmin and INmax is the voltage applied across terminals 7(COM) and 8 (INPUT 1) or 9 (INPUT 2).

OUTmin and OUTmax is the voltage across terminals 1 (OUT 1) and 2 (OUT 2) that connect to the lower board.

Calibraon Procedure

1. Ensure that switch SW501 on the -PCM board is properly set.

2. Connect (but do not power) the analog input signal as follows.

- Connect the signal negave (-) to terminal 7 (COM).

- For a current signal or a 0 - ± 25 VDC voltage signal, connect the signal posive (+) to terminal 8 (INPUT 1).

- For a 0 - ± 250 VDC voltage signal, connect the signal posive (+) to terminal 9 (INPUT 2).

3. Calibrate the regenerave drive’s MIN SPD trim pot full CCW and the MAX SPD trim pot full CW.

4. Apply AC line voltage and the analog input signal.

5. Set the input signal to INmin.

6. Adjust the MIN OUT trim pot (P503) so that the output voltage is OUTmin.

7. Set the analog input signal to INmax.

8. Calculate the test point voltage, Vtp;

9. Adjust the SIGNAL INPUT ADJ trim pot (P501) so that the voltage between terminals 7 (COM) and 10 (TP) is Vtp.

10. Adjust the MAX OUT trim pot (P502) so that the voltage output signal is OUTmax.

11. Repeat steps 4, 5, 6, 7, 9, and 10 using the same values.

Vtp = where m =

INmax* m

2

OUTmax - OUTmin

INmax - INmin

Connections

COMPOL REVTPINPUT 2INPUT 1COM+15-15L2L1OUT 2OUT 1

115 230

INPUT VOLTAGE SELECT

T501

SIGNAL

INPUT

ADJUST

SW501

R501

IC505

1-5mA

4-20mA

10-50mA

P502

P503

MAX

OUT

MIN

OUT

C501

C502

C503

C504

IC501

IC502

IC503

IC504 123

P501

SW502

C506 C505 C508 C507

115/230

VAC Line

S0 on

base

unit

S2 on

base

unit

0 - ± 25 VDC

1 - 5 mA

4 - 20 mA

10 - 50 mA

0 - ± 250 VDC

Direction Switch /

Polarity Reversal Switch

Startup

Select Switch (SW501)

Set the signal select switch SW501 based on the input signal type to be used.

Select Switch (SW502)

Set voltage select switch SW502 to either 115 or 230 to match the AC line voltage.

- Verify that no foreign conducve material is present on the printed circuit board.

- Ensure that all dip switches are properly set.

1. Apply the minimum analog voltage.

2. Apply AC line voltage.

3. Enable the drive.

4. Slowly advance the analog input signal. The motor slowly accelerates as the analog input signal is

raised. Connue unl the desired speed is reached.

5. Remove AC line voltage from the drive to coast the motor to a stop.

SELECT SWITCHES

STARTUP

INPUT

SIGNAL

LEVEL

1 - 5 mA

4 - 20 mA

10 - 50 mA

VDC

Other Minarik Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Asus

Asus AAEON BOXER-6406-ADN user manual

ABB

ABB COM600 3.4 user manual

Link electronics

Link electronics SDI to Analog Composite & Y/C DigiFlex 1159 Specification sheet

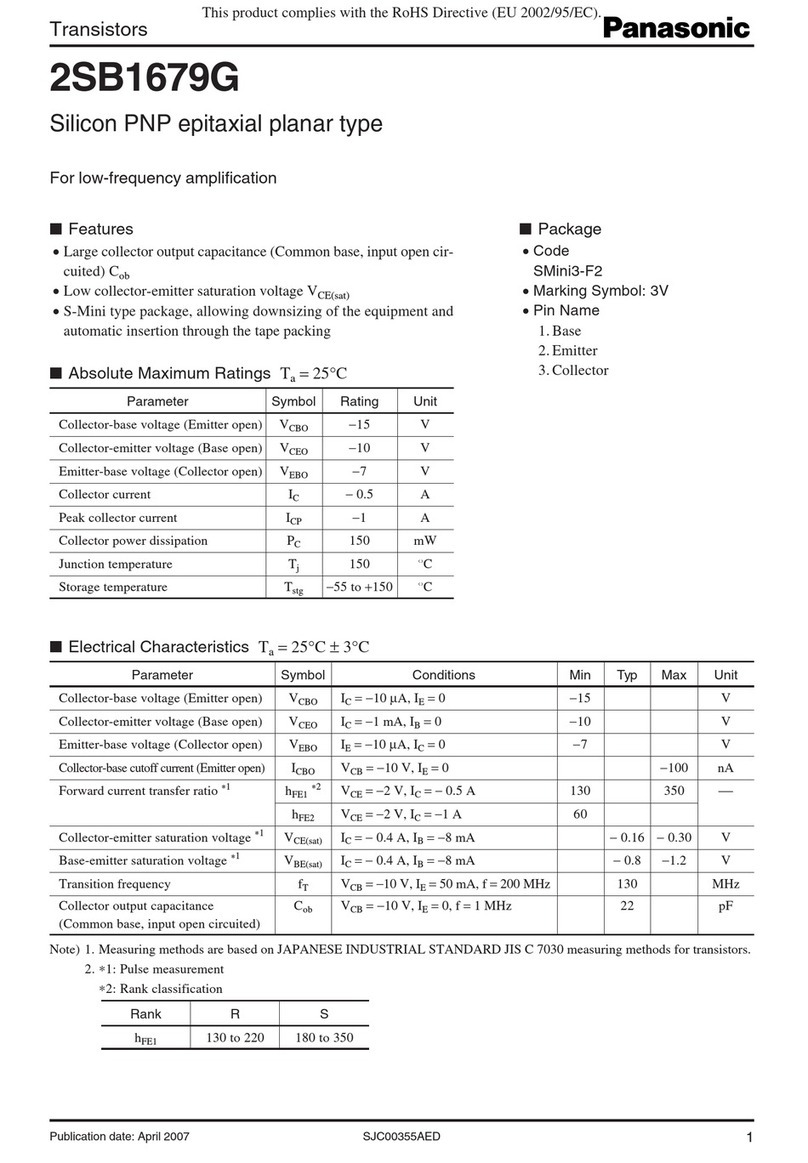

Panasonic

Panasonic 2SB1679G Specification sheet

ThermoKey

ThermoKey EPS Technical manual

INUX3D

INUX3D TerraPi Xtreme DUO Assembly instructions