Table of contents

1 Introduction......................................................................................................................................... 3

1.1 Read the manual......................................................................................................................................................... 3

1.2 This is what operating instructions look like .......................................................................................................... 3

1.3 This is what lists look like........................................................................................................................................... 3

1.4 This is what menu items and softkeys look like..................................................................................................... 3

1.5 This is what the safety instructions look like.......................................................................................................... 3

1.6 Hotline.......................................................................................................................................................................... 4

2 Safety instructions...............................................................................................................................5

2.1 General notes .............................................................................................................................................................. 5

2.2 Intended use................................................................................................................................................................ 5

2.3 Initial inspection.......................................................................................................................................................... 5

2.4 Before operational startup........................................................................................................................................ 5

3 Recommendations for installation .......................................................................................................6

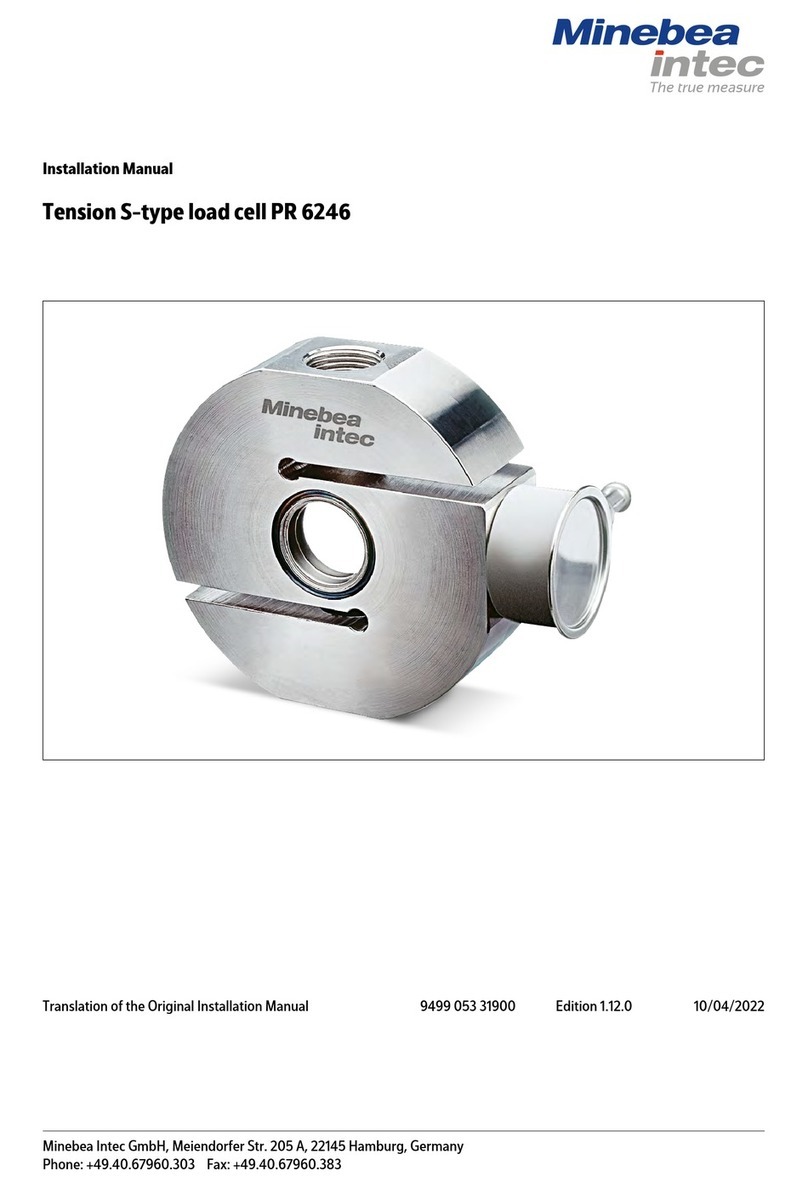

3.1 Load cell and constrainer arrangement..................................................................................................................6

3.2 Selecting maximum capacity.................................................................................................................................... 7

4 Specifications ......................................................................................................................................8

4.1 Equipment supplied with the load cell....................................................................................................................8

4.2 General information...................................................................................................................................................8

4.3 Possible marking of the load cell for the Ex area ..................................................................................................8

4.4 Dimensions .................................................................................................................................................................. 9

4.5 Ordering information.................................................................................................................................................9

4.6 Technical data ........................................................................................................................................................... 10

4.7 PR 6007/00 Mounting kit........................................................................................................................................12

4.7.1 Setting up the PR 6007/00 mounting kit ...................................................................................................12

4.7.2 Dimensions of PR 6007/00 mounting kit...................................................................................................13

5 Installation......................................................................................................................................... 14

5.1 Safety instructions.................................................................................................................................................... 14

5.2 Mounting without mounting kit..............................................................................................................................15

5.3 Mounting with PR 6007/00 mounting kit.............................................................................................................15

5.3.1 List of items......................................................................................................................................................15

5.3.2 Assembly ......................................................................................................................................................... 16

5.4 Configuring overload protection ............................................................................................................................17

6 Connection......................................................................................................................................... 18

6.1 General information................................................................................................................................................. 18

6.2 Load cell ..................................................................................................................................................................... 19

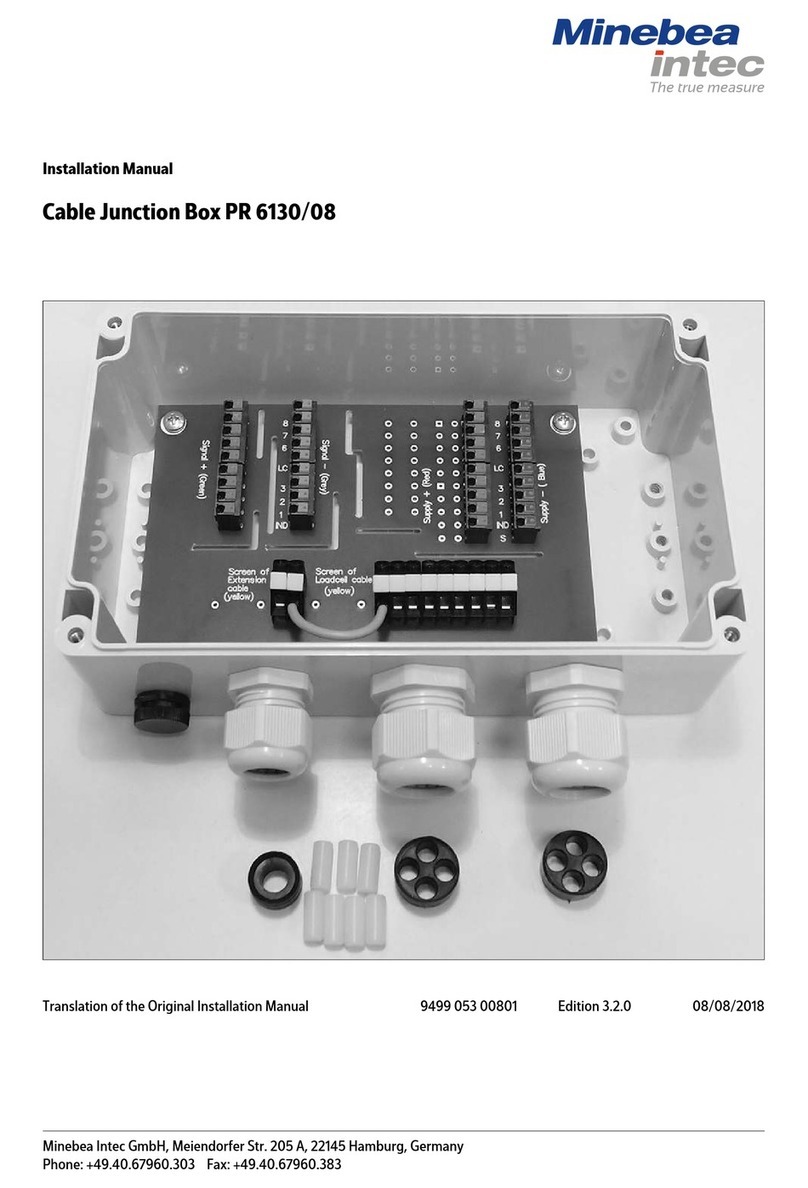

6.3 Cable connections .................................................................................................................................................... 19

Beam Type Load Cell PR 6207 Table of contents

Minebea Intec EN-1