Minivator 2000 Series Installation Manual

5

This manual is the intellectual copyright of Minivator Ltd. No changes may be made without prior consultation with Minivator Ltd. This manual may not be reprinted without the agreement of Minivator Ltd ©

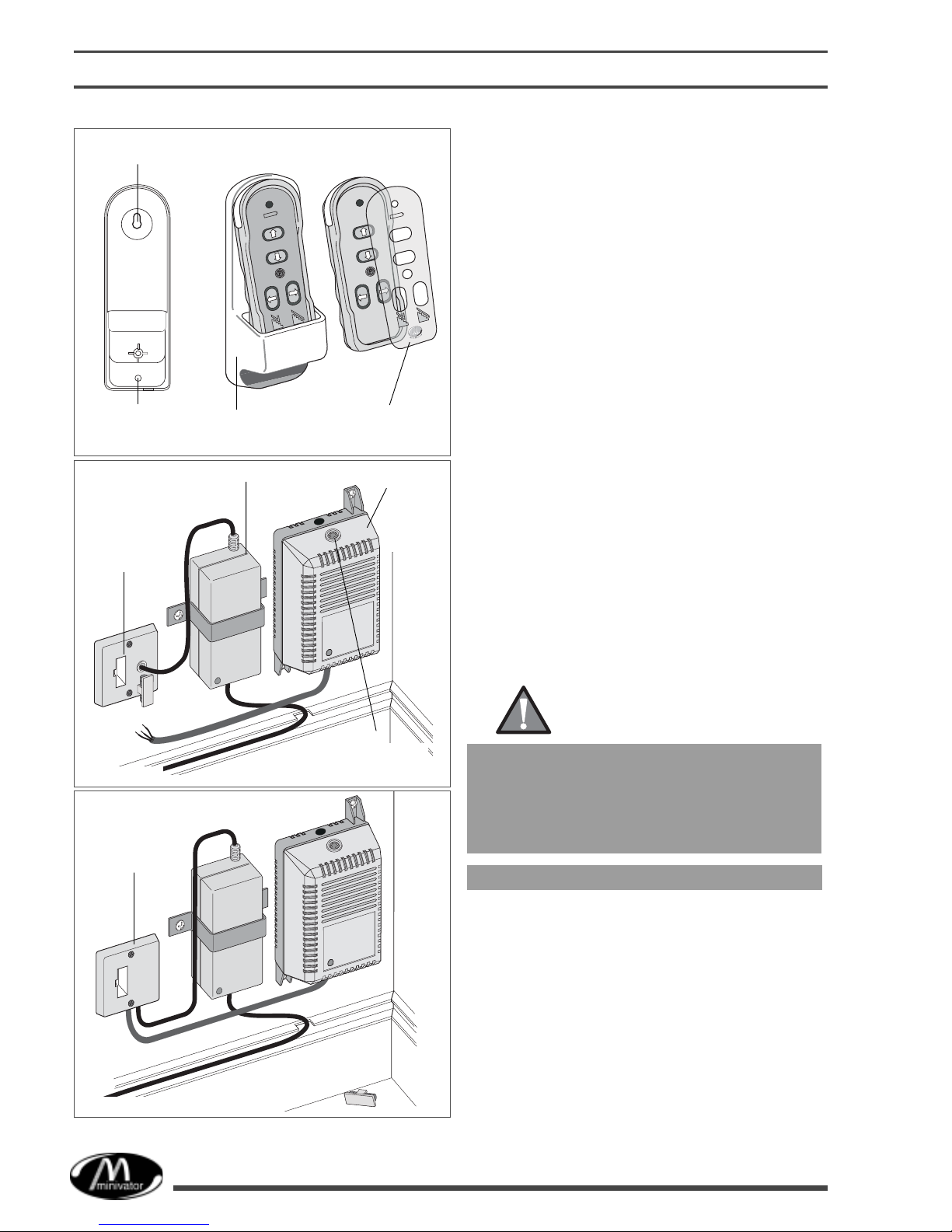

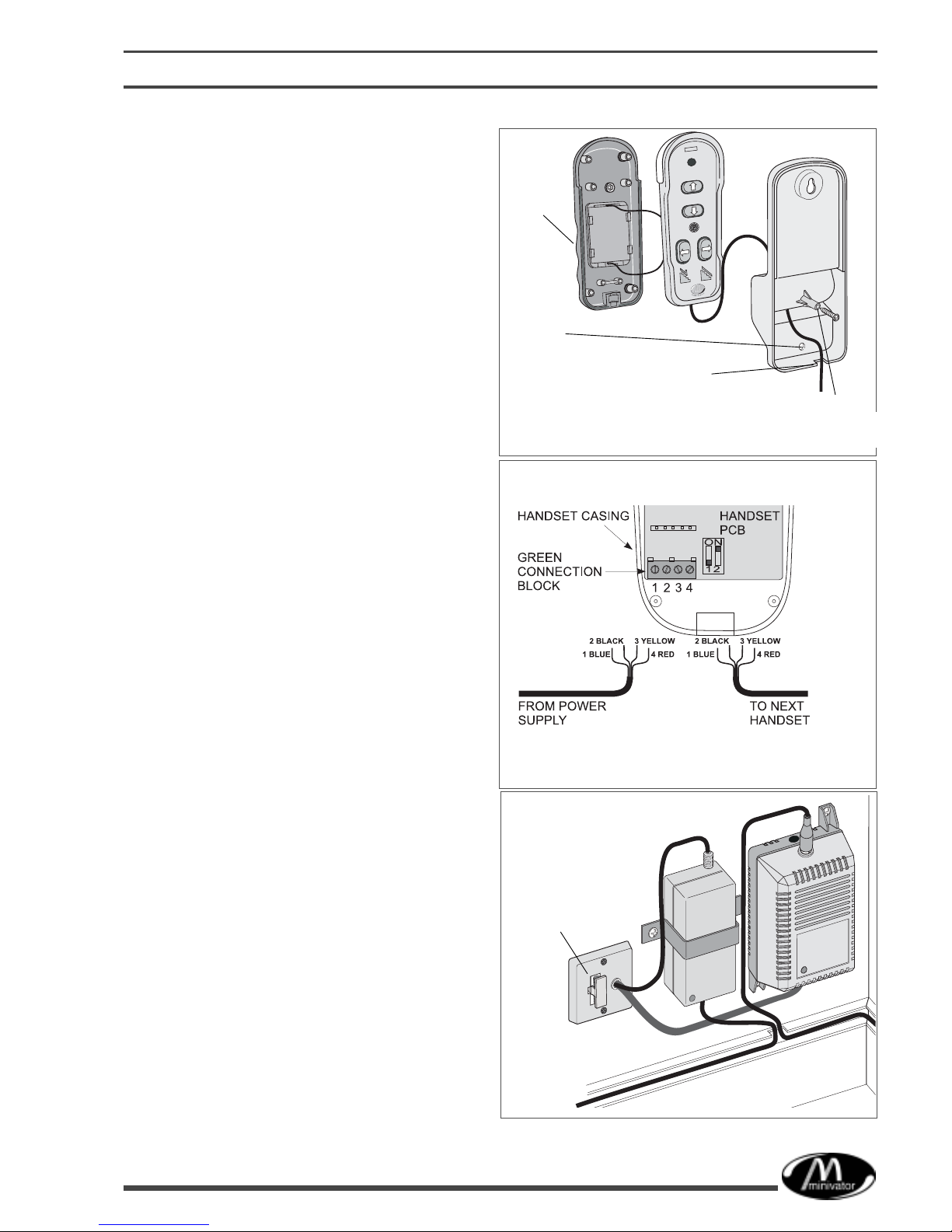

Fig. 2

To install the power supply and handsets

Assess the most appropriate position for the

power supply(ies), and the handset battery back

up box, where it (they) will cause the least

inconvenience for a pedestrian user of the

staircase, and agree the siting with the client.

(This is typically in a corner of the staircase,

where it (they) will be protected by the track

curvature).

Note: Ensure that all components are checked

off against the supplied assembly drawings

before commencing the installation.

Handsets are pre-pro rammed at Minivator as

stand alone units. If only 2 are to be used they

do not require hard wirin , simply fit the 3

batteries into each unit. (Show the client how to

chan e the batteries).

Note: Where multiple handsets are to be

installed (more than ) a separate handset

power supply has to be installed.

Typical schematic drawin s are shown in

Appendix 5 and 6.

Note: It is recommended that a fused mains

spur should be used as a power supply.

If one is not available a connection will have to

be made via an appropriate wall socket, usin

a fused plu .

1Where multiple handsets are used fit all

cables in the most unobtrusive position,

usin 4 core cable, and daisy-chain the

wirin . (Refer to Appendix 5 and 6).

Note: Minivator recommend the use of

16mm self adhesive cable trunkin for a

neater and more secure fittin .

2Where trunkin is bein used, notch or drill

cable entrances/exits as close as possible

to handsets, power supplies, etc, for the

neatest installation (Fi . 2,3).

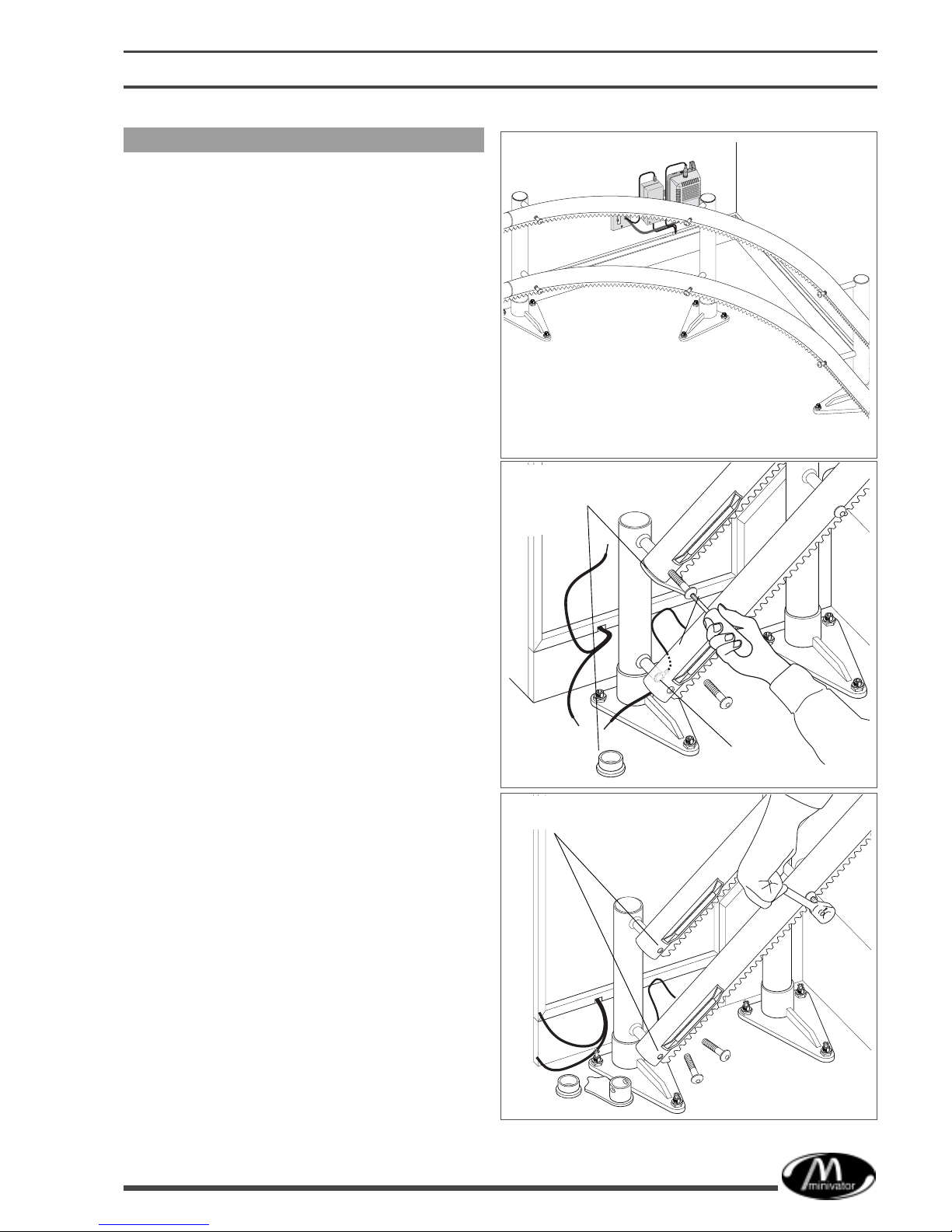

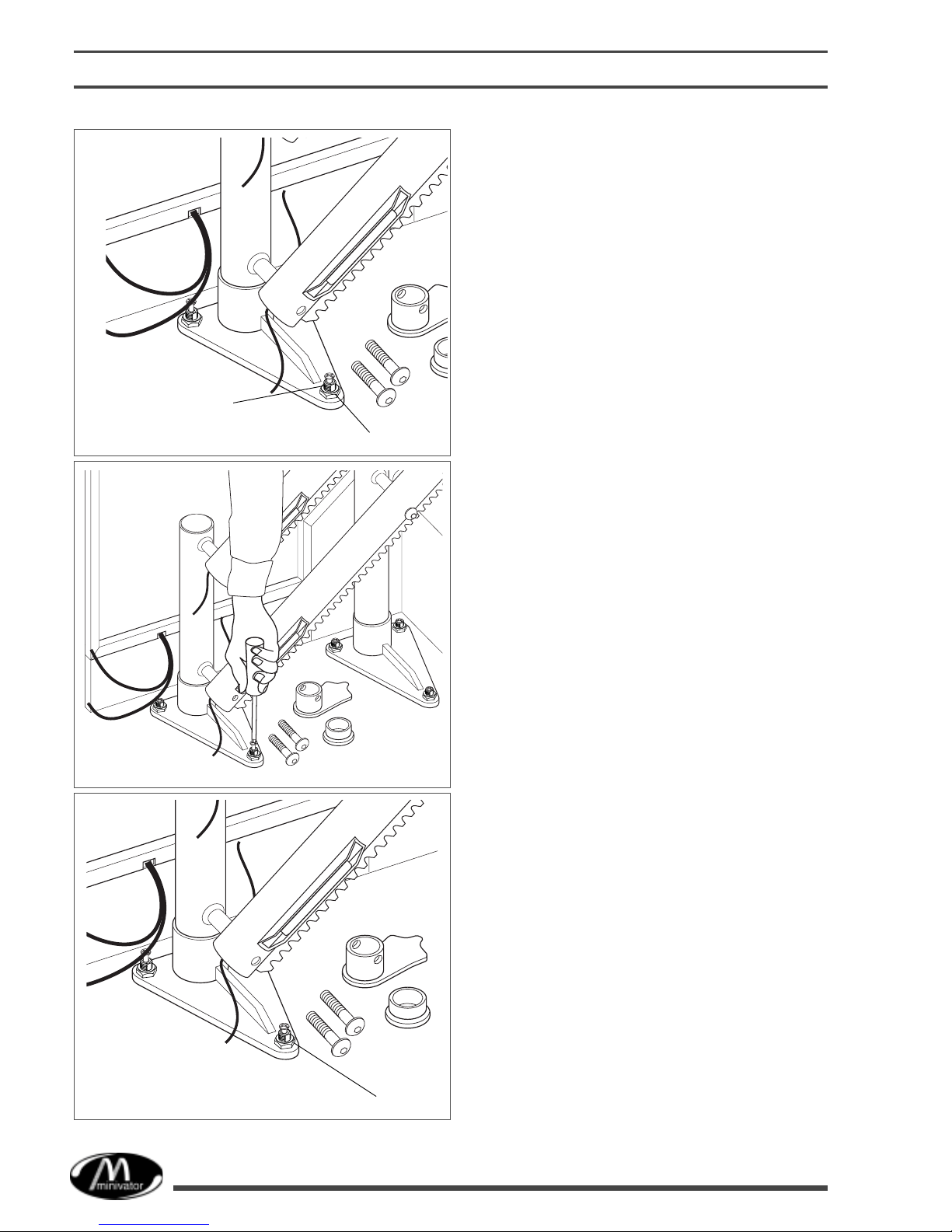

3Mark the positions required for the stairlift

power supply, and if required the handset

power supply. Use the mountin plate and/

or bracket to act as a template (Fi . 4).

Note: If the handset power supply has

mounting lugs, use the lugs as your template.

Notch out

trunking

for cable

installation

to power

supplies

Fig. 3

Notch out trunking for

cable installation

to charge points and

handsets.

ONLY CLIP COVER IN

PLACE WHEN CABLING I

ATI FACTORY

Fig. 4

tairlift power

supply bracket

Handset power supply

(With lugs)

Fused

spur

4 core handset

cable