1. About this document

MiR500 User guide (en) 06/2020 - v.1.4 ©Copyright 2018-2020: Mobile Industrial Robots A/S. 6

1. About this document

This user guide explains how to set up and start operating your MiR500 and provides

examples of simple missions you can expand to your purposes. This guide also contains

information regarding the external and internal components of MiR500 along with a guide

for proper maintenance of the robot. You will also find information regarding safety and

specifications needed to commission a safe MiR500 robot application.

This guide explains how to set up and start operating your MiR500. You will also find

information regarding safety precautions that must be considered when operating MiR500.

NOTICE

Save this manual. It contains important safety and operating instructions.

1.1 Where to find more information

At www.mobile-industrial-robots.com, several additional resources are available. To access

more information, sign in to the Distributor site with your distributor account at

http://www.mobile-industrial-robots.com/en/account/. The following resources are

available:

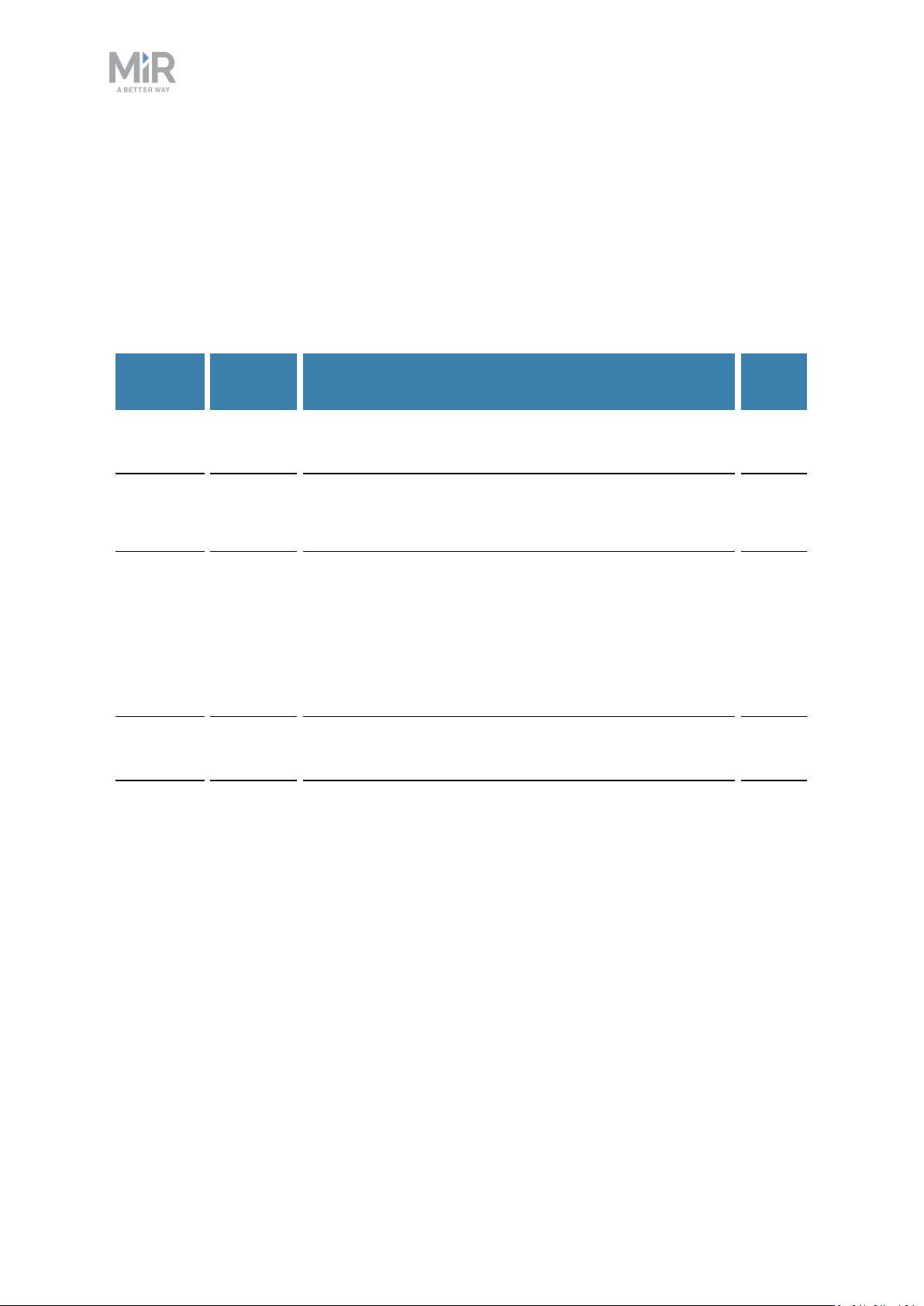

•Quick starts describe how you start operating MiR robots quickly. This document is in

print in the box with the robots. Quick starts are available in multiple languages.

•User guides provide all the information you need to operate and maintain MiR robots.

User guides are available in multiple languages.

•Risk Analysis Guides include guidelines on how to create a risk assessment of your robot

solution.

•Commissioning guides describe how to commission your robot safely and prepare it to

operate in the workplace.

•Operating guides describe how to set up and use top modules and accessories, such as

charging stations, hooks, shelf lifts, and pallet lifts.

•Getting started guides describe how to set up products that are mainly software-based,

such as MiR Fleet.

•Reference guides contain descriptions of all the elements of the robot interface and MiR

Fleet interface. Reference guides are available in multiple languages.

•REST API references for MiR robots, MiR hooks, and MiR Fleet.