7. Press the clamp down and position the turning tool with the

cutting edge over the middle of the counterbore diameter. If

the turning tool is set too low, release the locking screw and

twist the feed nut upwards anticlockwise.

8. If not yet done, release the blocking screw. Turn the crank

handle clockwise and slowly move the feed nut off and on in

the same direction. Stop when the turning tool is slightly

touching the counterbore seat (spotting). Gently tighten the

locking screw.

9. Press the clamp down and position the turning tool just

before the counterbore seat. Release the clamp.

10. Release the locking screw. Set the desired seat depth

using the feed nut. Gently tighten the locking screw once

again. Do not feed more than 0,1mm in a single step!

11. Hold the gear sleeve on the knurled surface with your

thumb and index finger. Turn the crank handle evenly

clockwise. Once the turning tool has reached the wall of the

counterbore, slow down the rotation slightly and allow the

gear sleeve to gently make contact with your fingers. As

soon as the cutting edge is reaching the sidewall of the

counterbore, the cutting pressure and therefore the

rotational resistance will increase. Do not turn the crank

handle anticlockwise in this step!

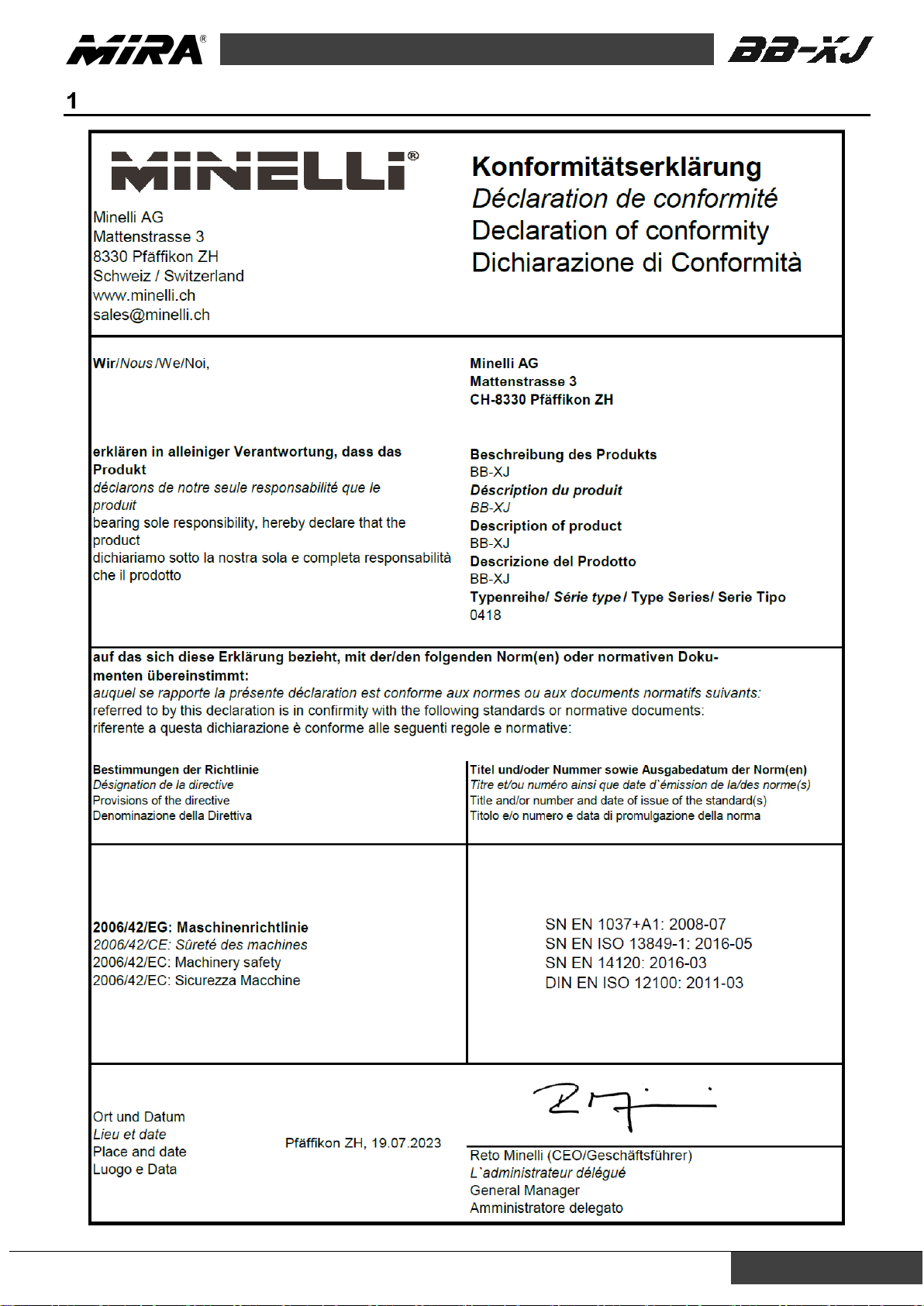

12. Check the deployment of the BB-XJ using a depth

gauge bolt. Reference height (gauge slide) to contact

surface => 60,000mm. The measurement is made to check

the depth of the counterbore after refacing the seat.

13. If final depth has not been achieved yet, repeat steps

9-12. If the final depth has been achieved, press the clamp

down and carefully slide back the turning tool up to the front

of the counterbore seat.

For further refacing of outstanding counterbore seats:

Repeat steps 3-13