3

1. GENERAL INFORMATION

1.1 PRODUCER

The firm Alfamacchine - ITW/AMP can boast more than 10

years of experience in the construction of Woodworking

Machines. It is the acquired technological know-how,

developed during years of researches in strict touch with

manufacturing department and international

commercialization the best warranty that Alfamacchine can

grant to its customers.

TEL 1-800-322-4204 FAX 1-800-426-7019

1.3 CERTIFICATION

The machine is produced in conformity to the pertinent

European Community Norms in force at the moment of its

introduction on the market.

1.4 WARRANTY

ITW/AMP’s products are constructed to have a long life and

are tested one by one.

If, in spite of this if any damages or malfunctioning would

occur, the replacement of defective parts is warranted

(counting from the date written on the delivery bill) for a

period of:

- 24 months for mechanical components

- 12 months for pneumatic part

The driver blade is tested for about 1.000.000 working

cycles.

The Warranty does not include the sending of technical staff.

The repair interventions will be performed at ITW/AMP and

the freight of shipment will be entirely charged to the

Customer.

The warranty does not cover the damages caused by an

inappropriate use of the machine or not corresponding to

the instructions described in this handbook.

The warranty decays in case of unauthorized modifications

or because of accidental damages or tampering performed

by unqualified personnel.

1.2 ASSISTANCE CENTERS

ITW/AMP is represented both in North and South America

by a numerous and prepared sales organization. Contact

our firm to get the number of your local distributor.

For every need regarding Use, Maintenance or Request of

Spare Parts, the Customer should call the authorized service

centers or directly to ITW/AMP, specifying the machine

identification data impressed on the plate.

The warranty also decays in case you use V-nails different

from the original ITW/AMP ones.

To take advantage of warranty services, it is necessary at the

moment you receive your machine to completely fill out

the warranty card and send it back as soon as possible to

ITW/AMP.

The warranty will be valid after the ITW/AMP records it.

1.5 PRE-ARRANGEMENTS CHARGED TO

THE CUSTOMER

It is the customer’s duty, on times agreed with the producer,

to execute what is indicated in our documentation.

Things normally charged to the customer:

•Premises predisposition, included building works and/

or canalization eventually requested

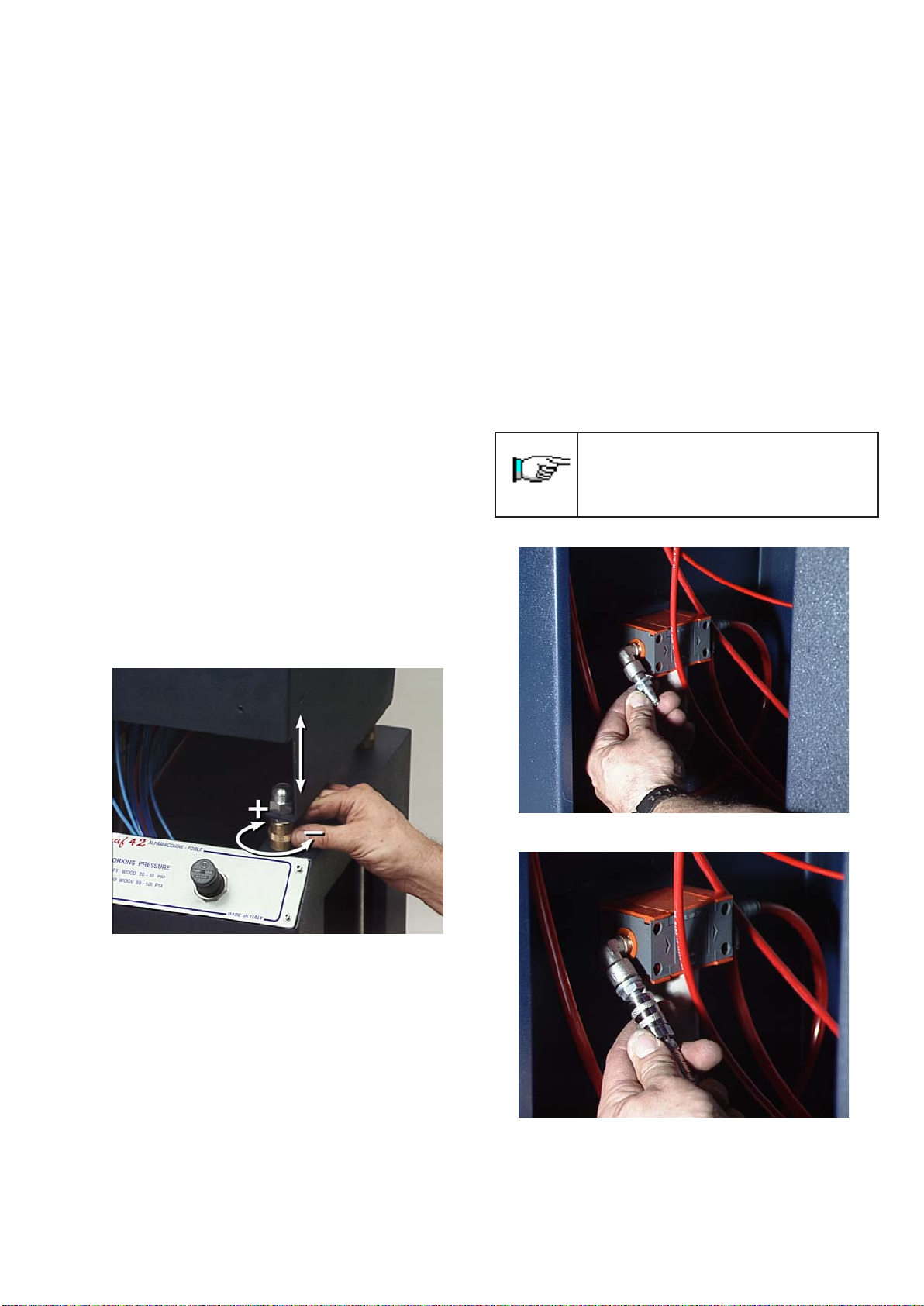

•Pneumatic supply of compressed air (see the paragraph

4.9.6)

1.6 HANDBOOK STRUCTURE

The customer must pay an extreme attention to the

indications reported in this handbook. The proper Pre-

Arrangement, Installation and Use of the Machine,

constitute the basis of a correct customer-distributor

relationship.

1.6.1 Object and contents

The goal of this handbook is to provide to the customer all

the necessary information so that, besides the proper use of

the machine, He would be able to run it in complete

autonomy and safety. The handbook contains information

concerning the technical aspects, machine working and

standstill, maintenance, spare parts and safety. Before making

any operation on the machine, the qualified technicians

and operators must carefully read these instructions. In case

you are in doubt about the correct interpretation of these

instructions, call your distributor & have them explanation

it to you.

1.6.2 Users

This handbook is made both for operators and technicians

authorized to the machine maintenance.

The operators can not execute operations reserved to the

maintainence staff or to the qualified technicians.

The producer does not answer to damages derived from not-

observing this prohibition.

1.6.3 Preservation

The instruction handbook must be kept very closed to the

machine & in a special container protecting it from liquids

and whatever could compromise its legibility