Mitsubishi Electric Mr. Slim PSA-RP71KA User manual

Other Mitsubishi Electric Air Conditioner manuals

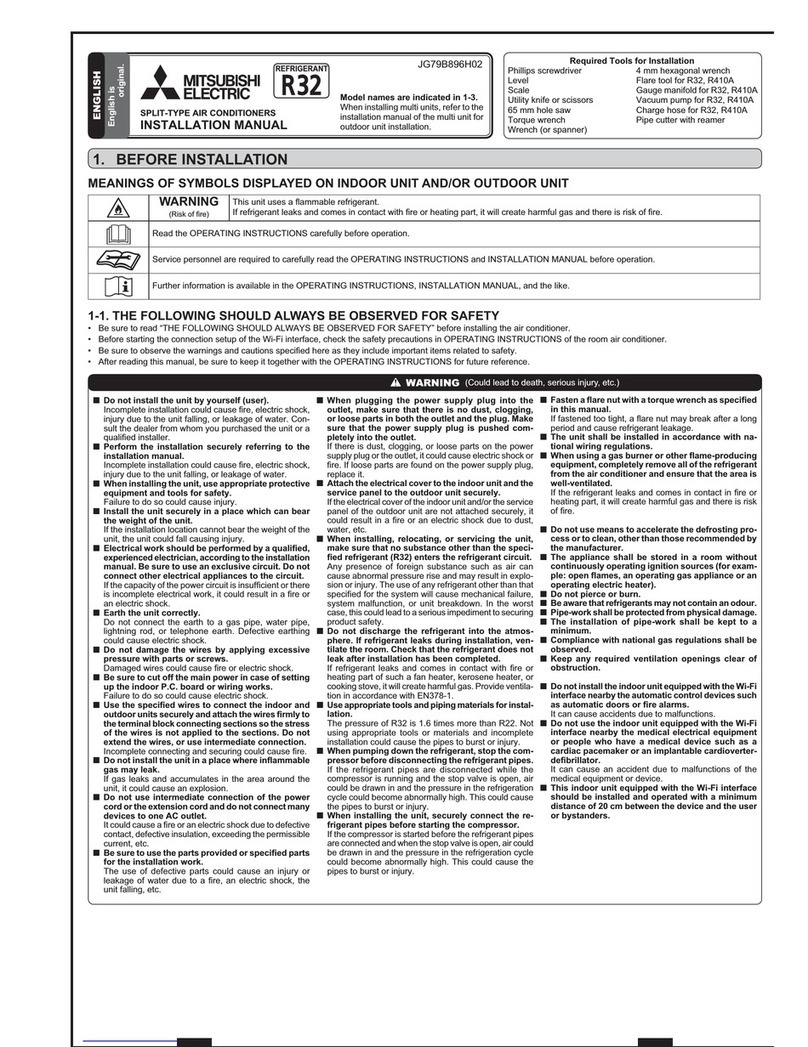

Mitsubishi Electric

Mitsubishi Electric PEAD-A24AA4 User manual

Mitsubishi Electric

Mitsubishi Electric MSZ-HA25VA-E1 User manual

Mitsubishi Electric

Mitsubishi Electric PU-P71VHA 2.UK Series User manual

Mitsubishi Electric

Mitsubishi Electric MSZ-AP60VG User manual

Mitsubishi Electric

Mitsubishi Electric PEA-RP250WKA Installation manual

Mitsubishi Electric

Mitsubishi Electric MSZ-SF35VE3 User manual

Mitsubishi Electric

Mitsubishi Electric PAC-YG21CDA User manual

Mitsubishi Electric

Mitsubishi Electric PLA-RP35EA User manual

Mitsubishi Electric

Mitsubishi Electric MSC-GA20VB- E1 User manual

Mitsubishi Electric

Mitsubishi Electric t-NEXT DF DX 011 P1 S User manual

Mitsubishi Electric

Mitsubishi Electric PLFY-P08NBMU-E2 Operating manual

Mitsubishi Electric

Mitsubishi Electric MUZ-HR VF Series User manual

Mitsubishi Electric

Mitsubishi Electric MSZ-AP50VGK User manual

Mitsubishi Electric

Mitsubishi Electric BRANCH BOX PAC-MKA53BC User manual

Mitsubishi Electric

Mitsubishi Electric MSZ-EF25VEW User manual

Mitsubishi Electric

Mitsubishi Electric Mr.Slim PCA-A-KA4 User manual

Mitsubishi Electric

Mitsubishi Electric MXZ-8B140VA Operating manual

Mitsubishi Electric

Mitsubishi Electric CMB-WM350F-AA User manual

Mitsubishi Electric

Mitsubishi Electric PAC-MKA50BC User manual

Mitsubishi Electric

Mitsubishi Electric Mr. Slim MSZ-FD09NA User manual