10 11

OCH673C

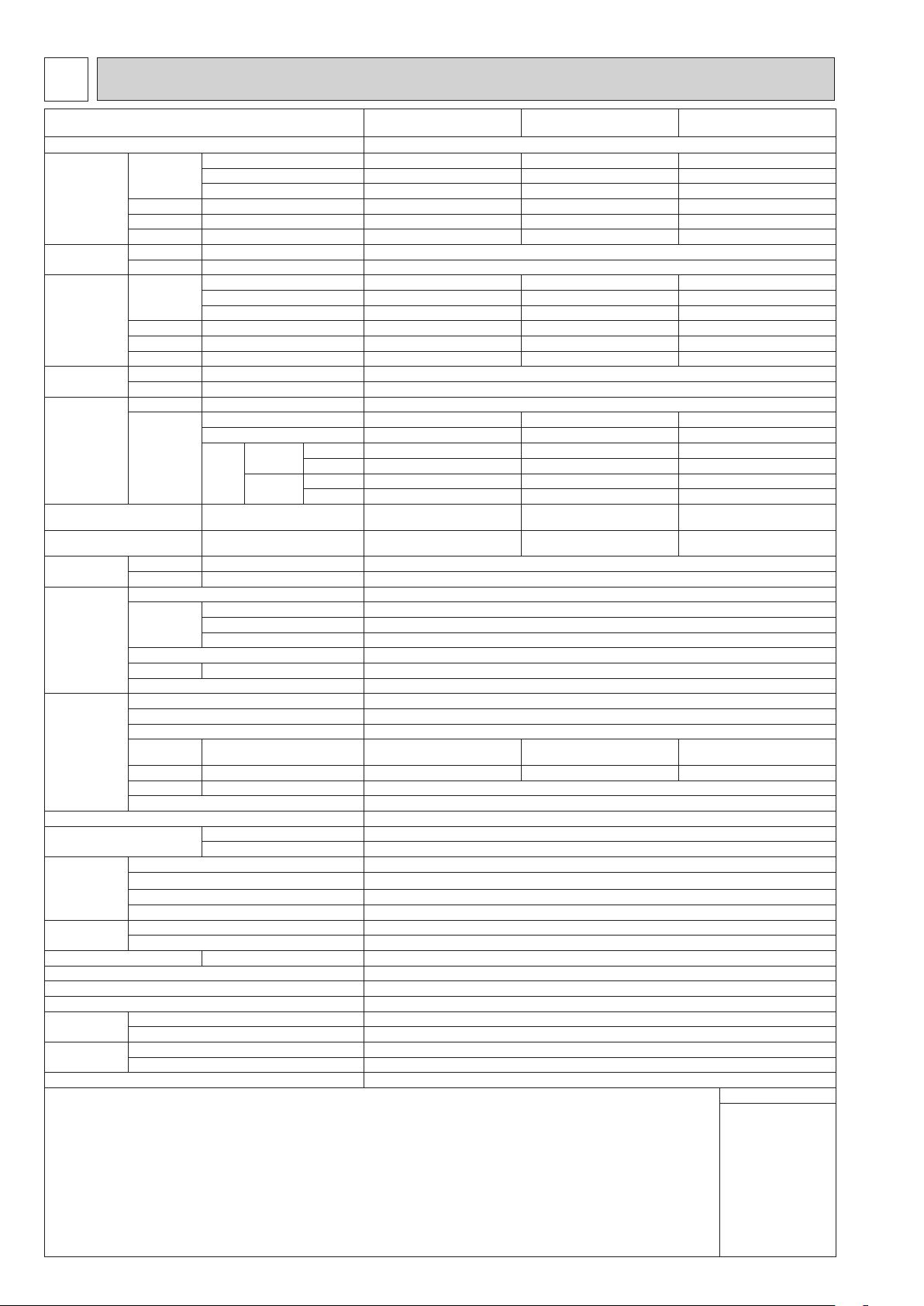

3SPECIFICATIONS

Model PUMY-P112VKM4(-BS)

PUMY-P112VKM4R1(-BS) PUMY-P125VKM4(-BS)

PUMY-P125VKM4R1(-BS) PUMY-P140VKM4(-BS)

PUMY-P140VKM4R1(-BS)

Power source 1-phase 220-230-240 V, 50 Hz; 1-phase 220-230 V, 60 Hz

Cooling capacity

(Nominal) kW*112.5 14.0 15.5

kcal/h*110,750 12,040 13,330

Btu/h*142,650 47,768 52,886

Power input kW 2.79 3.46 4.52

Current input A 12.87-12.32-11.80, 12.87-12.32 15.97-15.27-14.64, 15.97-15.27 20.86-19.95-19.12, 20.86-19.95

COP kW/kW 4.48 4.05 3.43

Temp. range of

cooling Indoor temp. W.B. 15 to 24°C

Outdoor temp. D.B. −5 to 52°C *3, *4

Heating capacity

(Nominal) kW*214.0 16.0 18.0

kcal/h*212,040 13,760 15,480

Btu/h*247,768 54,592 61,416

Power input kW 3.04 3.74 4.47

Current input A 14.03-13.42-12.86,14.03-13.42 17.26-16.51-15.82,17.26-16.51 20.63-19.73-18.91,20.63-19.73

COP kW/kW 4.61 4.28 4.03

Temp. range of

heating Indoor temp. D.B. 15 to 27°C

Outdoor temp. W.B. −20 to 15°C

Indoor unit

connectable Total capacity 50 to 130% of outdoor unit capacity

Model/

Quantity CITY MULTI P10 - P140 / 9 P10 - P140 / 10 P10 - P140 / 12

Branch box*6P15 - P100 / 8 P15 - P100 / 8 P15 - P100 / 8

Mixed

system Branch box

1unit

*6CITY MULTI P15 - P140 / 5 P15 - P140 / 5 P15 - P140 / 5

Branch box P15 - P100 / 5 P15 - P100 / 5 P15 - P100 / 5

Branch box

2unit

*6CITY MULTI P15 - P140 / 3 or 2*5P15 - P140 / 3 P15 - P140 / 3

Branch box P15 - P100 / 7 or 8*5P15 - P100 / 8 P15 - P100 / 8

Sound pressure level (SPL)

(measured in anechoic room) dB <A> 49/51 50/52 51/53

Sound power level (PWL)

(measured in anechoic room) dB <A> 69/71 70/72 71/73

Refrigerant

piping diameter Liquid pipe mm (inch) 9.52 (3/8)

Gas pipe mm (inch) 15.88 (5/8)

FAN *2 Type × Quantity Propeller Fan x 2

Airow rate m³/min 110

L/s 1,833

cfm 3,884

Control, Driving mechanism DC control

Motor output kW 0.074+0.074

External static press. 0

Compressor Type × Quantity Scroll hermetic compressor x 1

Manufacture Mitsubishi Electric Corporation

Starting method Inverter

Capacity

control % Cooling 26 to 100

Heating 20 to 100 Cooling 24 to 100

Heating 18 to 100 Cooling 21 to 100

Heating 17 to 100

Motor output kW 2.9 3.5 3.9

Case heater kW 0

Lubricant FV50S (2.3litter)

External nish Galvanized Steel Sheet Munsell No. 3Y 7.8/1.1

External dimension H × W × D mm 1,338×1,050×330(+40)

inch 52-11/16 × 41-11/32 × 13(+1-9/16)

Protection

devices High pressure protection High pressure Switch

Inverter circuit (COMP./FAN) Overcurrent detection, Overheat detection(Heat sink thermistor)

Compressor Compressor thermistor, Overcurrent detection

Fan motor Overheating, Voltage protection, Overcurrent detection

Refrigerant Type × original charge R410A 4.8 kg

Control Linear expansion valve

Net weight kg (lb) 122 (269)

Heat exchanger Cross Fin and Copper tube

HIC circuit (HIC: Heat Inter-Changer) HIC circuit

Defrosting method Reversed refrigerant circuit

Drawing External BK01N346

Wiring BH78B813

Standard

attachment Document Installation Manual

Accessory Grounded lead wire ×1

Optional parts Joint: CMY-Y62-G-E, Header: CMY-Y64/68-G-E, Branch box: PAC-MK31/32/33/51/52/53BC(B)

Remarks *1 Nominal cooling conditions *2 Nominal heating conditions

Indoor : 27°C D.B./19°C W.B. [81°F D.B/66°F W.B.] 20°C D.B. [68°F D.B.]

Outdoor : 35°C D.B. [95°F D.B.] 7°C DB/6°C W.B. [45°F D.B./43°F W.B.]

Pipe length : 7.5 m [24-9/16 ft] 7.5 m [24-9/16 ft]

Level difference : 0 m [0 ft] 0 m [0 ft]

*3 10 to 52:D.B. [50 to 126_F D.B.], when connecting following models: PKFY-P15/20/25VBM, PKFY-P10/15/20/25/32VLM, PFFY-P20/25/32VLE(R)

M, PFFY-P20/25/32VKM, PFFY-P20/25/32VCM, PEFY-P25/32/40VMA3; and M series, S series, and P series type indoor unit.

*4 −15 to 52:D.B. [50 to 126_F D.B.], when using an optional air protect guide [PAC-SH95AG-E]. However, this condition does not apply to the indoor

unit listed in *3.

*5 When connecting 7 indoor units via branch box, connectable CITY MULTI indoor units are 3; connecting 8 indoor units via branch box, connectable

CITY MULTI indoor units are 2.

*6 At least two indoor unit must be connected when using branch box.

Notes : 1. Nominal conditions *1, *2 are subject to ISO 15042.

2. Due to continuing improvement, above specications may be subject to change without notice.

Unit converter

kcal/h = kW × 860

Btu/h = kW × 3,412

cfm = m³/min × 35.31

lb = kg/0.4536

Above specication data

is subject to rounding

variation.