SECTION 2

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

SECTION 3

SERVICING DIAGRAMS

1. STANDING PC BOARDS FOR SERVICING ......................... 3-1

2. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION ..................................... 3-2

2-1. Precautions for Part Replacement .................................... 3-2

2-2. Solid Resistor Indication .................................................... 3-2

2-3. Capacitance Indication ....................................................... 3-2

2-4. Inductor Indication ............................................................. 3-3

2-5. Waveform and Voltage Measurement .............................. 3-3

2-6. When Replaced ROM ICs or Upgraded Firmware ........ 3-4

3. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM .......................................................... 3-5

4. BLOCK DIAGRAMS .................................................................. 3-7

4-1. Overall Block Diagram ...................................................... 3-7

4-2. Power Supply Block Diagram ........................................... 3-9

4-3. Front Display, Power Switch Block Diagram ................ 3-10

4-4. Main Block Diagrams ....................................................... 3-13

4-5. Output Block Diagram ..................................................... 3-17

5. CIRCUIT DIAGRAMS ............................................................. 3-18

5-1. Power Supply Circuit Diagram ....................................... 3-18

5-2. Front Display, Power Switch Circuit Diagram .............. 3-21

5-3. Main Circuit Diagram ...................................................... 3-24

5-4. Output Circuit Diagram ................................................... 3-41

5-5. Motor System Circuit Diagrams ..................................... 3-47

6. PC BOARDS .............................................................................. 3-49

6-1. Power Supply PC Board ................................................... 3-49

6-2. Main PC Board ................................................................. 3-50

6-3. Output PC Board .............................................................. 3-55

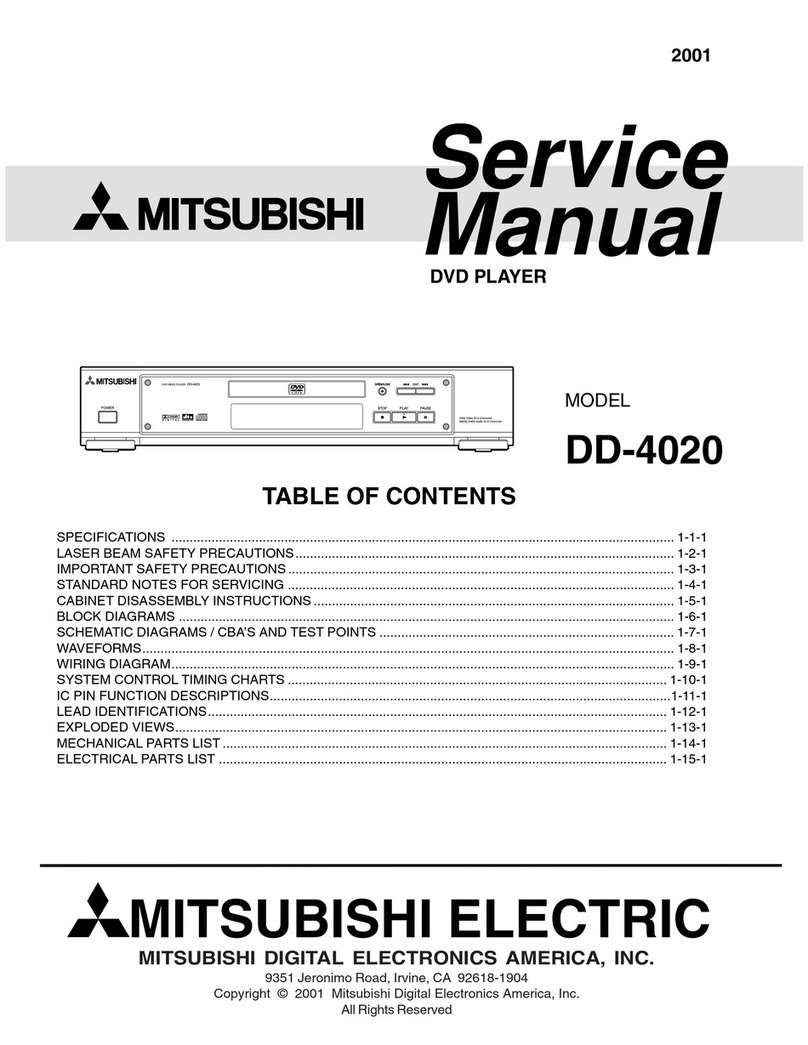

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

1. PREPARATION FOR SERVICING ......................................... 1-1

2. LOCATION OF MAIN PARTS AND

MECHANISM PARTS ............................................................... 1-2

2-1. Location of Main Parts ....................................................... 1-2

2-2. Location of Mechanism Parts ............................................ 1-3

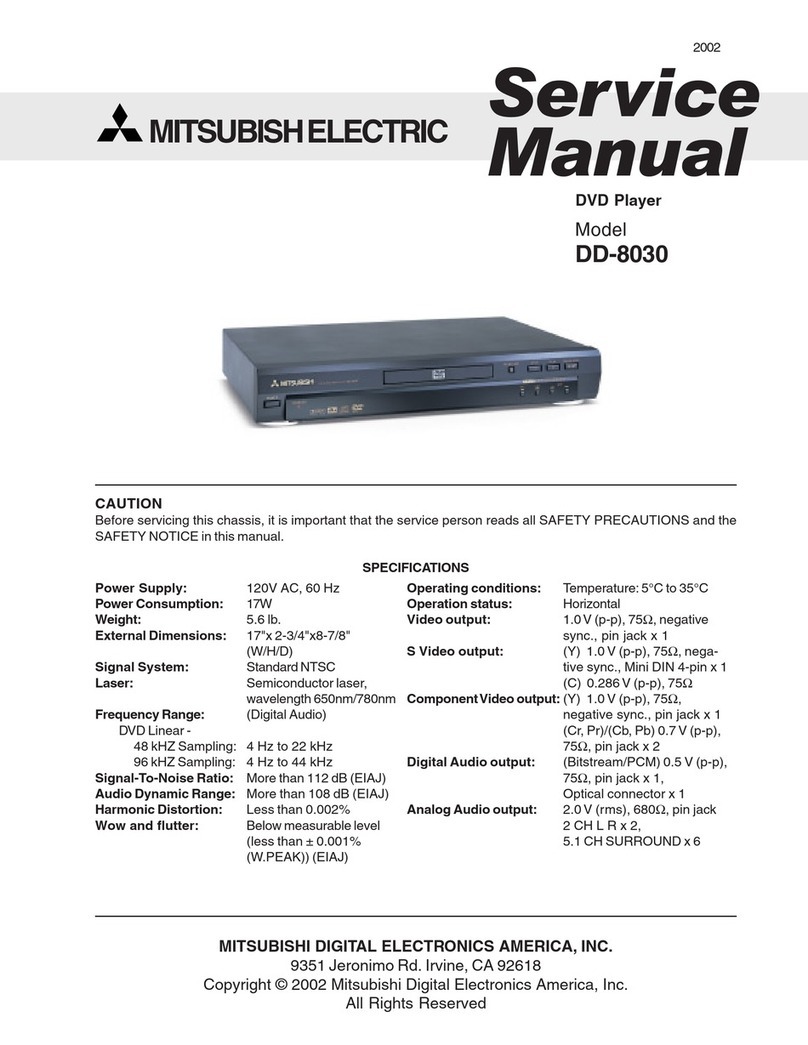

1. REPLACEMENT OF MECHANICAL PARTS ...................... 2-1

1-1. Cabinet Replacement .......................................................... 2-1

1-1-1. Top Cover ........................................................................ 2-1

1-1-2. Clamper Stay ................................................................... 2-1

1-1-3. Tray Panel ....................................................................... 2-2

1-1-4. Front Panel and Tray ..................................................... 2-3

1-1-5. Rear Panel ....................................................................... 2-3

1-2. PC Board Replacement ...................................................... 2-4

1-2-1. Main PC Board ............................................................... 2-4

1-2-2. Output PC Board ............................................................ 2-4

1-2-3. Power PC board .............................................................. 2-5

1-2-4. Front PC Board ............................................................... 2-5

1-3. Mechanism Parts ................................................................. 2-6

1-3-1. Mechanism Chassis Assembly ....................................... 2-6

1-3-2. Loading Belt .................................................................... 2-6

1-3-3. Loading Motor ................................................................ 2-7

1-3-4. Sub Chassis (with a pickup mechanism) ...................... 2-7

1-3-5. Pickup Mechanism Assembly ........................................ 2-8

1-3-6. Gear A Assembly, Gear B and

Rack Gear Assembly ...................................................... 2-8

1-3-7. Feed Motor ...................................................................... 2-9

3. TROUBLESHOOTING .............................................................. 1-6

3-1. Main Circuit ........................................................................ 1-6

3-1-1. Servo System ................................................................... 1-6

3-1-2. Location Diagram of Servo Test Point ....................... 1-13

SECTION 4

PARTS LIST

SAFETY PRECAUTION ................................................................. 4-1

NOTICE ............................................................................................. 4-1

ABBREVIATIONS ........................................................................... 4-1

1. Integrated Circuit (IC) ............................................................ 4-1

2. Capacitor (Cap) ....................................................................... 4-1

3. Resistor (Res) ........................................................................... 4-1

4. EXPLODED VIEWS ................................................................... 4-2

4-1. Packing Assembly ............................................................... 4-2

4-2. Chassis Assembly ................................................................ 4-3

4-3. Mechanism Assembly ......................................................... 4-4

5. PARTS LIST ................................................................................ 4-5