JZ990D43601E

How to obtain manuals

How to obtain manuals

For product manuals or documents, consult with the Mitsubishi Electric dealer

from who you purchased your product.

Registration

The company names and product names described in this manual are the

trademarks or registered trademarks of their respective companies.

Safety Precaution (Read these precautions before use.)

This manual classifies the safety precautions into two categories:

and .

Depending on the circumstances, procedures indicated by may

also cause severe injury.

It is important to follow all precautions for personal safety.

In case of trouble, in spite of our best efforts in quality control, it may be

assumed to cause continuous running state due to failure of the clutch and

the brake, and hence it is advised to pay sufficient consideration to safety

measures at the machine side.

Store this manual carefully so that it can be referred to when required, and

make sure to send it to the end user.

Indicates that incorrect handling may cause

hazardous conditions, resulting in death or severe

injury.

Indicates that incorrect handling may cause

hazardous conditions, resulting in medium or slight

personal injury or physical damage.

Use protective cover.

The rotating elements are exposed outside, and the

hand or part of body may be injured if touching the

product. Install a protective cover, allowing smooth

ventilation, so that part of the body may not be in

contact with the machine. It is also recommended to

provide with a safety mechanism to stop the rotating

elements immediately when the cover is opened.

Mitsubishi Electric is not responsible for any damage or trouble caused by

repair, disassembly or modification of the product by any third party other than

Mitsubishi or specified agent.

For repair or disassembly services, therefore, please call the service network of

Mitsubishi.

Warranty

Exclusion of loss in opportunity and secondary loss from warranty liability

Regardless of the gratis warranty term, Mitsubishi shall not be liable for

compensation to:

(1) Damages caused by any cause found not to be the responsibility of Mitsubishi.

(2) Loss in opportunity, lost profits incurred to the user by Failures of Mitsubishi

products.

(3) Special damages and secondary damages whether foreseeable or not,

compensation for accidents, and compensation for damages to products other

than Mitsubishi products.

(4) Replacement by the user, maintenance of on-site equipment, start-up test run

and other tasks.

For safe use

This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in a

device or system used in purposes related to human life.

Before using the product for special purposes such as nuclear power, electric

power, aerospace, medicine or passenger movement vehicles, consult with

Mitsubishi Electric.

This product has been manufactured under strict quality control. However

when installing the product where major accidents or losses could occur if the

product fails, install appropriate backup or failsafe functions in the system.

1. Cautions before use

1) The powder is contained inside, and hence never give impact or incline the

product.

2) Don't leave the product in a damp place.

3) Don't pull or tear the lead wire, and handle with care.

Never use the unit in an atmosphere in which

inflammation or explosion is expected.

While slipping, a spark may be ignited on the internal

working surface. Never use in a flammable or explosive

atmosphere with oil or grease. Enclose the main body

when using near flammable material such as cotton.

When enclosed, however, it must be noted that the

allowable heat dissipation is lowered.

Keep the product away from water, oil, and grease.

Not only the working surface but also the product main

body should be protected from water, oil, and grease. If

water, oil, or grease is on the main body, it may flow to the

working surface and may remarkably lower the torque. As

a result, the machine may not stop at the specified point

due to inertial run, or may run at an abnormal speed.

Such abnormal operation of the machine may cause injury.

Check the environments.

Never use in a place exposed to dust, high temperature,

dew condensation, rain and wind, oil mist. Don't install

directly in a place exposed to vibration or impact. Or it

may lead to damage or malfunction of the product or

deterioration of performance.

This manual confers no industrial property rights or any rights of any other kind,

nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

held responsible for any problems involving industrial property rights which may

occur as a result of using the contents noted in this manual.

Never suspend the product by holding the leadwire.

Or the lead wire may be broken and the product may drop

to cause injury.

Hold the product itself when attaching or detaching.

If the product is not used for a long time, store the brake

at a non-humid place, or take measures to protect the

brake from moisture.

If the inside of the product is moistened, the product may

be corroded and operation may not be possible, or the

performance may be deteriorated.

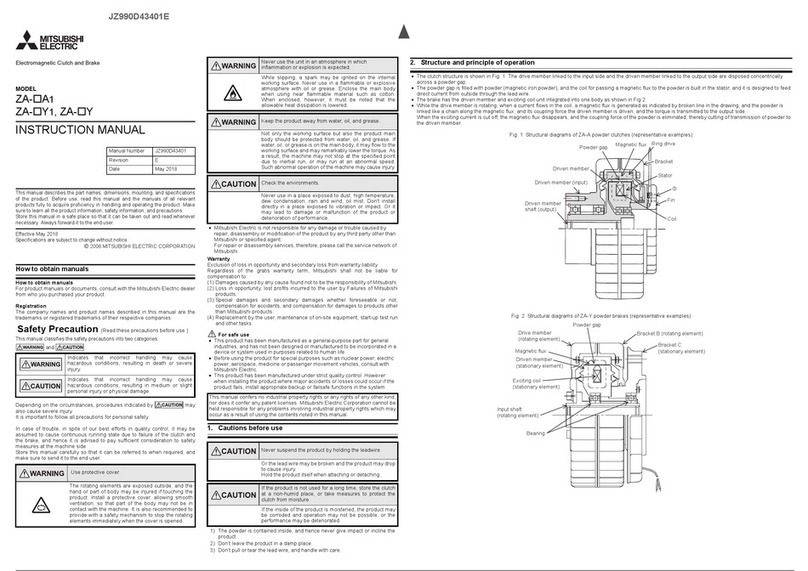

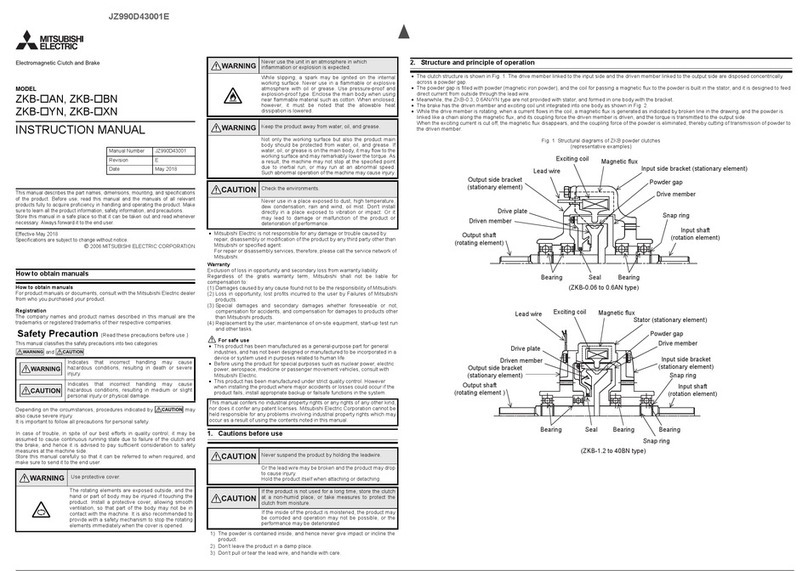

2. Structure and principle of operation

ZX-YN powder brake structure is shown in Fig. 1. The drive member fixed to the shafts and the stator, which has a coil for generating a magnetic flux around the

drive member, are disposed concentrically across a powder gap.

The powder gap is filled with powder (magnetic iron powder) that transmits the torque.

When a current flows in the coil, a magnetic flux is generated as indicated by broken line in the drawing, the powder is linked like a chain along the magnetic flux,

and its coupling force generates torque corresponding to the current. When the exciting current is cut off, the magnetic flux disappears, the coupling force of the

powder is eliminated, and torque is no longer generated.

Fig. 1 ZX-YN powder brakes (representative examples)

Magnetic flux

Drive member

Powder gap

Lead wire

Exciting coil Stator

(stationary element)

Input shaft

(trotating element)

3. Assembling of clutch, brake

1) Make sure there is enough clearance when installing the product to

prevent impact and undue force from being applied to the product

during assembly work.

Especially, when inserting the shaft, make sure to fix the shaft part of

the drive member.

2) Install the brake so that the shafts become horizontal.

3) Pay sufficient attention to the height of set bolts. (The depth is 6mm in

all bolts.)

4) The voltage polarity is not specified.

Turn off the power, and make sure rotating elements

are stopped.

Never work while rotating, or it may cause electric

shock or injury. When mounting, dismounting, or

adjusting, turn off the power source, and make sure

the rotating elements are stopped still. At this time,

be careful not to have fingers or hand pinched.

Tighten bolts to specified torque, and lock securely.

Depending on the degree of tightening, the bolts may

be broken to cause injury. Using specified bolt

material, tighten bolts to specified torque, and lock

securely with adhesive, spring washer or the like as

specified. Besides, since the parts composing the

product rotate relatively to each other, the tightened

parts must be fixed securely for the safety of

operation.

The bolt strength and tightening torque are

designated in the specification.

Connect lead wires securely.

Otherwise it may lead to an electric shock.

Connect securely, both electrically and mechanically,

and insulate appropriately.

Be sure to connect a surge absorber parallel to the

exciting coil to cut off the direct current.

Cutting off the current may cause a large surge

voltage, and the surge voltage may deteriorate the

peripheral units.

For this reason, be sure to use a surge absorber,

such as a diode, varistor, and protective resister.

Use wire size suited to current capacity.

If wire of smaller current capacity is used, the

insulating coating may melt down to cause insulation

failure, possibly leading to electric shock, current

leak, or fire.

The specified current of the product is designated in

the specification.

4. Operation

If a shock is applied to the brake and brake during transportation, powder may

be scattered inside the brake. For this reason, before starting regular operation,

perform running-in while following the procedure below to collect powder into

the powder gap, if necessary.

1) Running-in procedure

Rotate the input shaft at approximately 200 r/min. for one minute and set

the excitation current to a value that is one quarter to three quarters of the

rated excitation current. Excite the brake approximately 10 times using a 5

seconds ON, 10 seconds OFF cycle.

If running-in is not adequate and powder is distributed unevenly, repeat 5

seconds ON, 10 seconds OFF cycle at rated excitation for approximately

10 times.

2) End of running-in

While the running-in is insufficient, the torque output may be low or the

torque may fluctuate, but as the running-in becomes sufficient and the

powder comes to work effectively, a stable torque corresponding to the

exciting current is produced.

After the running-in, start regular operation.

Depending on the conditions of use, the drive member surface temperature

may rise considerably. Use the brake while keeping the surface

temperature below 100°C. If the surface temperature exceeds 100°C, relax

the operation conditions, and prevent overheat of the brake.

The above-described surface temperature is a reference value. Be sure to

use the brake within the allowable heat dissipation.

(Herein, the surface temperature is mentioned on the basis of the ambient

temperature of 30°C. The allowable ambient temperature range is 0 to

40°C.)

Never touch the product during operation.

The rotating elements are exposed outside, and the hand

or part of body may be injured if touching the product.

Install a protective cover, allowing smooth ventilation, so

that the hand or fingers may not be in contact with the

machine during operation, and also a safety mechanism

to stop the rotating elements immediately when the cover

is opened.

Never increase the rotating speed more than allowable.

If the rotating speed is raised more than allowable,

vibration increases to cause breakage and scattering of

powder, and it is very dangerous. Rotate within allowable

speed, and install protective cover.

Use thermometer when measuring temperature.

Don't touch directly by hand to avoid burns. Turn off the

power source, and make sure the rotating elements are

stopped still, and measure with thermometer.

Measure promptly.

5. Torque adjustment

The relation of torque and exciting current is almost proportional as shown in

Fig. 2, and therefore by adjusting the current, the torque can be easily adjusted.

Set to a proper value in consideration of the finish of the product or working

condition.

Fig.2 Exciting current vs. torque characteristics

(representative examples)

Use within rated torque.

If used over the rated torque, not only the performance

deteriorates, but also mechanical breakage or injury may

be caused. Hence, use with rated torque. In particular, it

must be noted that a torque over the rating may be cause

even if used at the rated current, and therefore check the

current-torque characteristic, and adjust the exciting

current.

(In the course of use, the torque gradually declines, and

therefore in manufacturing, a proper allowance is

considered initially.)

Use within the allowable heat dissipation.

If used over allowable heat dissipation, the brake may be

extremely heated, and the working surface may be

extremely hot and red. As a result, a fire may be caused.

In addition, the performance may be deteriorated. Be sure

to use within the allowable heat dissipation.

0

2

4

6

8

10

12

14

16

0 0.1 0.2 0.3 0.4 0.5 0.6

Exciting current (A)

Torque (N

·

m)

ZX-1.2YN-24

Rated voltage: DC24V

ZX-0.6YN-24

ZX-0.3YN-24

0

2

4

6

8

10

12

14

16

0 0.04 0.08 0.12 0.16

Rated voltage: DC80V

Exciting current (A)

Torque (N

·

m)

ZX-1.2YN-80

ZX-0.6YN-80

ZX-0.3YN-80

6. Maintenance

Check the following items.

1) When the powder is moist, the expected performance may not be

exhibited.

Be careful not to admit water or oily material inside the brake.

In particular, if used near the gear box, the oil may invade through the

shaft, and therefore perfect oil sealing is advised.

2) Replace the product when its life is expired. (Powder and bearing can

not be replaced.)

The product replacement timing cannot be indicated clearly because

the powder life varies depending on the conditions of use (slip rotation

speed, heat dissipation). Judge the replacement timing when the torque

decreases to 70% or less of the initial value. However, it is actually

difficult to check the torque.

Even if the torque has decreased, it increases when the exciting current

increases. Therefore, if the specified torque cannot be obtained at the

rated current, replace the product.

3) Check the coupling mounting bolts and others for looseness..

7. Troubleshooting

This product is replaced with a new product when its life span terminates

(powder and bearing can not be replaced).

Mitsubishi Electric is not responsible for any damage or trouble caused by

repair, disassembly or modification of the product by any third party other

than Mitsubishi or specified agent.

Turn off the power, and make sure rotating elements

are stopped.

Never work while rotating, or it may cause injury.

When checking, turn off the power source, and make

sure the rotating elements are stopped still. At this

time, be careful not to have fingers or hand pinched.

When disposing of this product at the end of its

service life, please follow local and national guideline

for the disposal of industrial products.

Trouble Cause Remedy

Torque output is low.

Torque is not

generated by

passing exciting

current.

Insufficient running-

in.

Powder is

moistened by water

or oil.

Deterioration of

powder.

Run in again.

Change product.

Torque is generated

without passing

current.

Torque fluctuates on

every rotation.

Defective bearing.

Deterioration or

sintering of powder.

Change product.

Surface temperature

exceeds 100°C. Overload. Relax the conditions

of use.

Use thermometer when measuring temperature.

Don't touch directly by hand to avoid burns. Turn off

the power source, and make sure the rotating

elements are stopped still, and measure with

thermometer.

Measure promptly.

MODEL

ZX-YN

INSTRUCTION MANUAL

This manual describes the part names, dimensions, mounting, and specifications

of the product. Before use, read this manual and the manuals of all relevant

products fully to acquire proficiency in handling and operating the product. Make

sure to learn all the product information, safety information, and precautions.

Store this manual in a safe place so that it can be taken out and read whenever

necessary. Always forward it to the end user.

Effective May 2018

Specifications are subject to change without notice.

2006 MITSUBISHI ELECTRIC CORPORATION

Manual Number JZ990D43601

Revision E

Date May 2018