–1–

1 PRECAUTIONS FOR DEVICES THAT USE R407C REFRIGERANT

Caution

Do not use the existing refrigerant piping.

• The old refrigerant and refrigerator oil in the existing

piping contains a large amount of chlorine which may

cause the refrigerator oil of the new unit to deterio-

rate.

Use refrigerant piping made of C1220 (CU-DHP) phos-

phorus deoxidized copper as specified in the *JIS

H3300 “Copper and copper alloy seamless pipes and

tubes”. In addition, be sure that the inner and outer

surfaces of the pipes are clean and free of hazard-

ous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

• Contaminants on the inside of the refrigerant piping

may cause the refrigerant residual oil to deteriorate.

*JIS: Japanese Industrial Standard

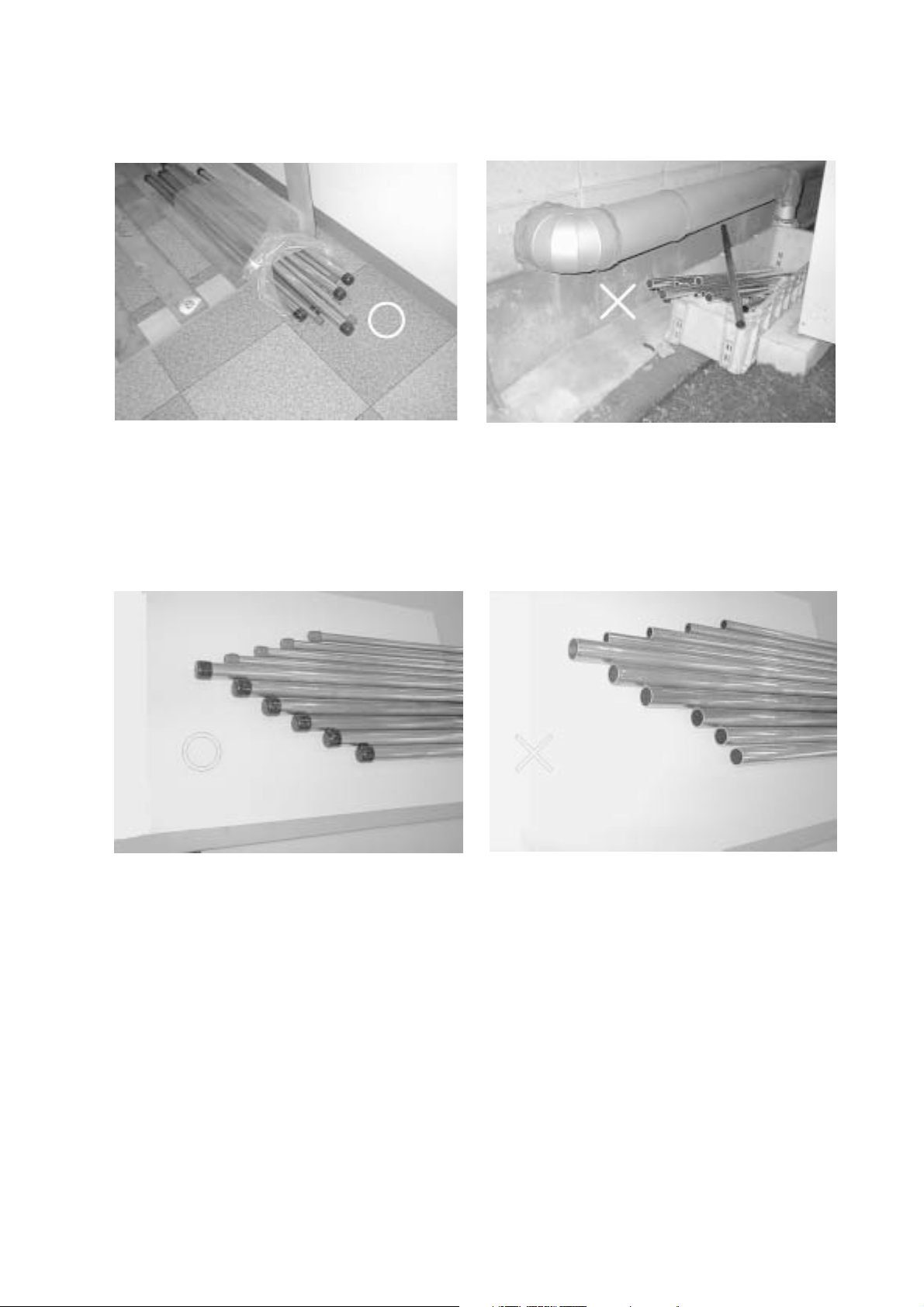

Store the piping to be used during installation indoors

and keep both ends of the piping sealed until just

before brazing. (Store elbows and other joints in a

plastic bag.)

• If dust, dirt, or water enters the refrigerant cycle, de-

terioration of the oil and compressor trouble may re-

sult.

Use ester oil, ether oil or alkylbenzene (small amount)

as the refrigerator oil to coat flares and flange con-

nections.

• The refrigerator oil will degrade if it is mixed with a

large amount of mineral oil.

Use liquid refrigerant to seal the system.

• If gas refrigerant is used to seal the system, the com-

position of the refrigerant in the cylinder will change

and performance may drop.

Do not use a refrigerant other than R407C.

• If another refrigerant (R22, etc.) is used, the chlorine

in the refrigerant may cause the refrigerator oil to de-

teriorate.

Use a vacuum pump with a reverse flow check valve.

• The vacuum pump oil may flow back into the refriger-

ant cycle and cause the refrigerator oil to deteriorate.

Do not use the following tools that have been used

with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, re-

verse flow check valve, refrigerant charge base,

vacuum gauge, refrigerant recovery equipment)

• If the conventional refrigerant and refrigerator oil are

mixed in the R407C, the refrigerant may deteriorated.

• If water is mixed in the R407C, the refrigerator oil may

deteriorate.

• Since R407C does not contain any chlorine, gas leak

detectors for conventional refrigerants will not react to

it.

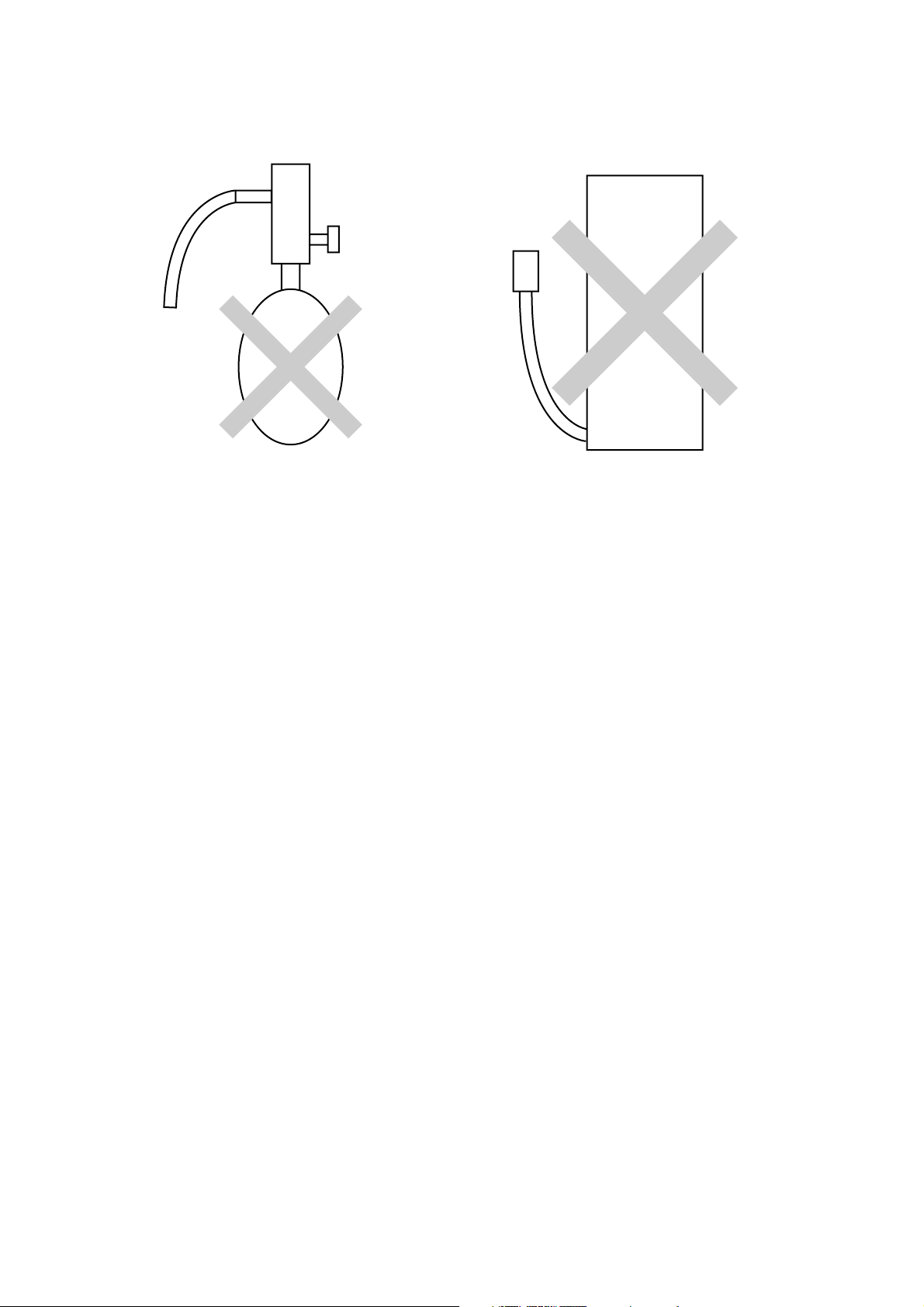

Do not use a charging cylinder.

• Using a charging cylinder may cause the refrigerant

to deteriorate.

Be especially careful when managing the tools.

• If dust, dirt, or water gets in the refrigerant cycle, the

refrigerant may deteriorate.

If the refrigerant leaks, recover the refrigerant in the

refrigerant cycle, then recharge the cycle with the

specified amount of the liquid refrigerant indicated

on the air conditioner.

• Since R407C is a nonazeotropic refrigerant, if addi-

tionally charged when the refrigerant leaked, the com-

position of the refrigerant in the refrigerant cycle will

change and result in a drop in performance or abnor-

mal stopping.