2Your company internal use only.Copyright (C) Mitsubishi Electric Corporation.

NR-242UM-13LND0,13-WS

FEATURES

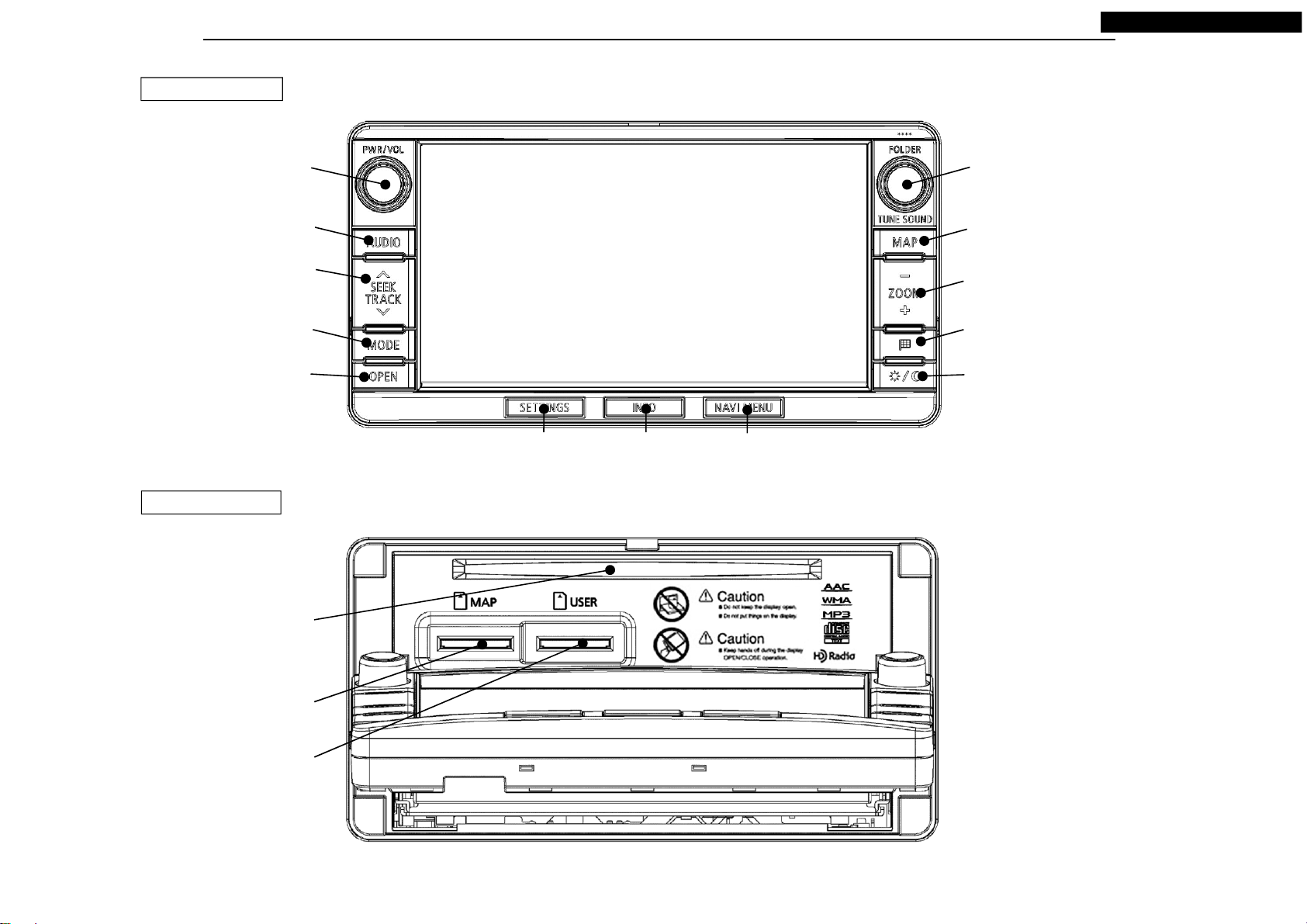

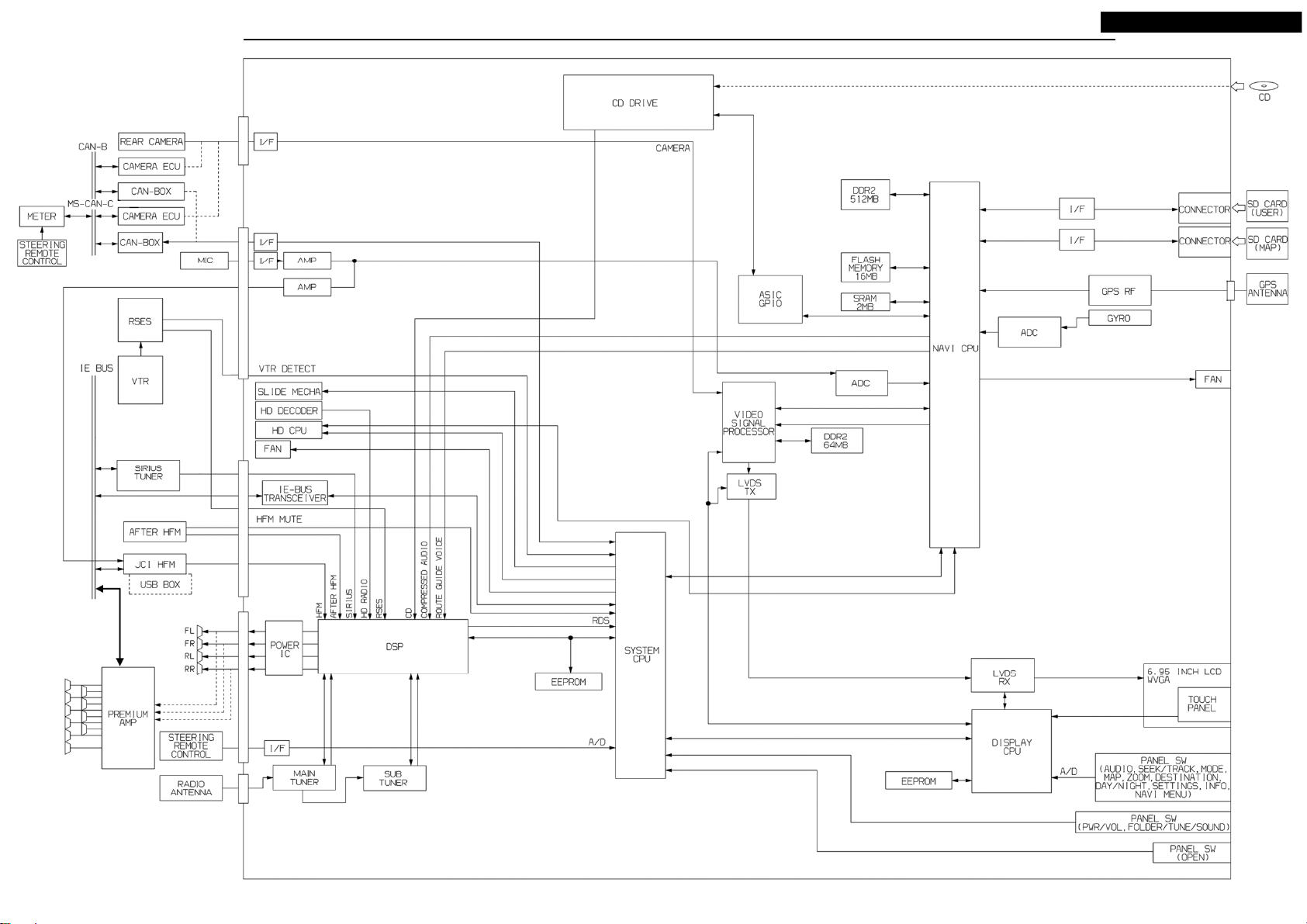

< Display Part >

●Panel design : Wide 2DIN size

●Button illumination : Umber

●LCD : 6.95inch WVGA

●Touch panel : Resistive type (Glass-Glass, Retardation film)

●Display U-com : M16C

< Navigation Part >

●Navi U-com : NaviJ3 (Working frequency : 533MHz)

●Work / Program memory

: DDR2-SDRAM 512MB

●Boot memory : Flash memory 16MB

●Back up memory : SRAM 2MB

●SD card (MAP data)

: Panasonic RP-SDP16G Series (16GB)

●GPS receiver : Built-in GPS-IP

●Gyro sensor : MEMS Gyro (Murata manufacturing)

●Voice recognition function

< Audio Part >

●Audio U-com : V850ES / SJ3

●DSP : SAF7741HV / N125 (DiRaNa2)

●Radio tuner : TEF7000HV / V3 (LeafDice x2)

●RBDS

●Traffic Information : NAVTEQ Traffic RDS

: HD-Traffic

●HD Radio : SAF3560HV / V1102 HD1.5 (Cayman)

●CD drive : Mitsubishi 8th CD mecha (8cm disc not supported)

(Supported Media : CD, CD-R, CD-RW)

(Supported Format : CD-DA, CD-ROM)

(Supported File : MP3, WMA, AAC)

●SD card (USER) : (Supported Media : SD, SDHC)

(Supported File : MP3, WMA, AAC, WAV)

●USB Audio play : via JCI external hands free module, or via Mitsubishi USB-BOX

●iPod Audio play : via JCI external hands free module, or via Mitsubishi USB-BOX

●Bluetooth Audio play

: via JCI external hands free module

< External Connect Part >

●Steering switch

●Cell phone : via JCI external hands free module

●iPod : via JCI external hands free module, or via Mitsubishi USB-BOX

●USB memory : via JCI external hands free module, or via Mitsubishi USB-BOX

●Rear camera

●Camera ECU connector (OUTLANDER and OUTLANDER PHEV)

: via outside CAN-BOX (MS-CAN-C)

Camera ECU connector (OUTLANDER SPORT, LANCER and LANCER SPORT BACK)

: via outside CAN-BOX (CAN-B)

●Premium amp : CV-0MW3R45-2, CV-0MW3R45-4, CV-0MW3R45-5,

CV-0MW3B45

●RSES : Built-in DISC drive

●VTR : via RSES

●Sirius tuner : CQ-0MU3IEB, CQ-0MU3IEB-C

●Hands free module

: JCI external hands free module,

For after JCI external hands free module

●USB-BOX : Mitsubishi