Contents

FOREWORD .......................................................................................................................................................i

PRECAITIONS....................................................................................................................................................i

WARRANTY........................................................................................................................................................i

NOTES ON OVERSEAS TRANSFER................................................................................................................i

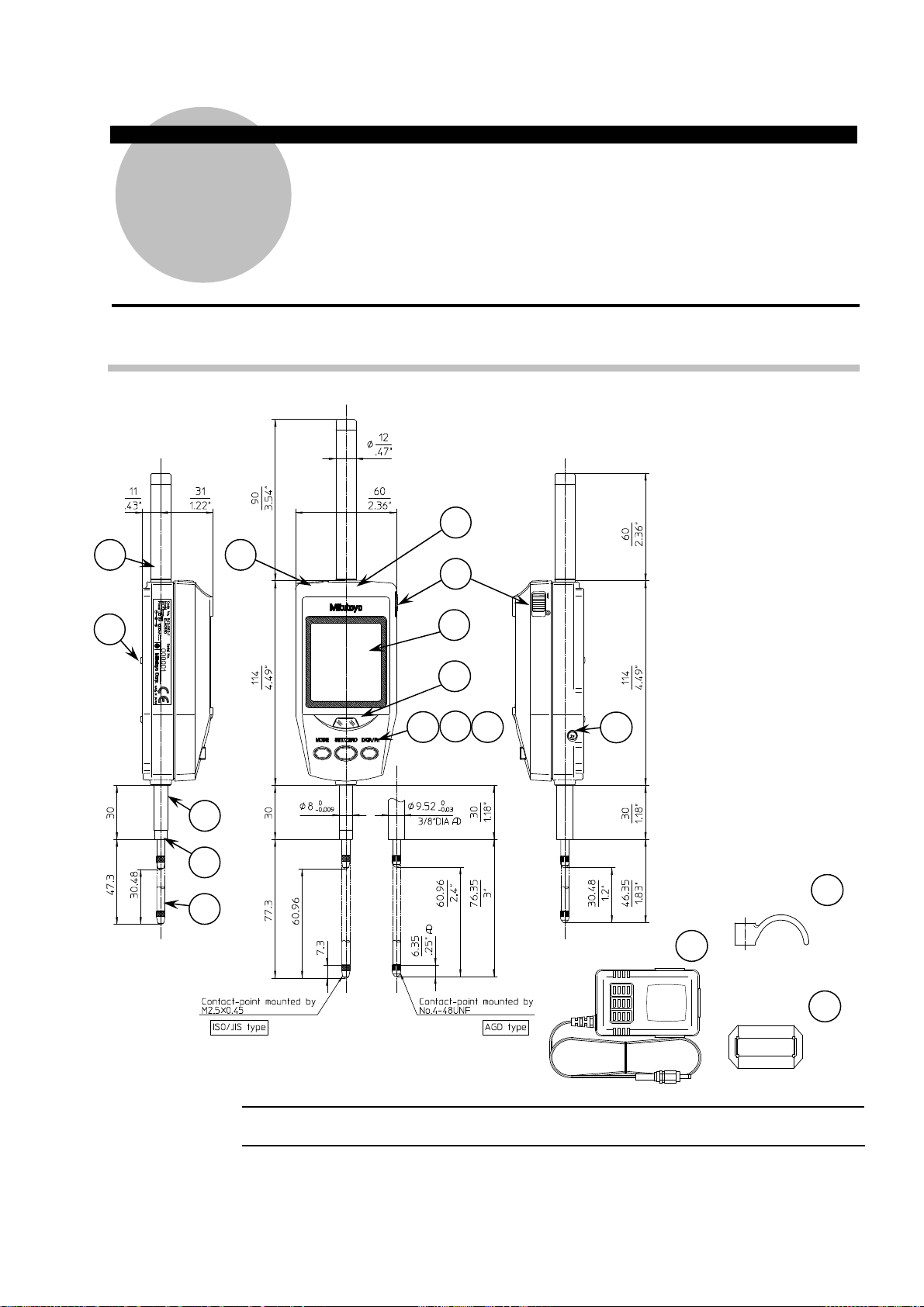

1 NAME OF RACH PART......................................................................................................................... 1-1

1.1 Part Names of the Main Unit......................................................................................................... 1-1

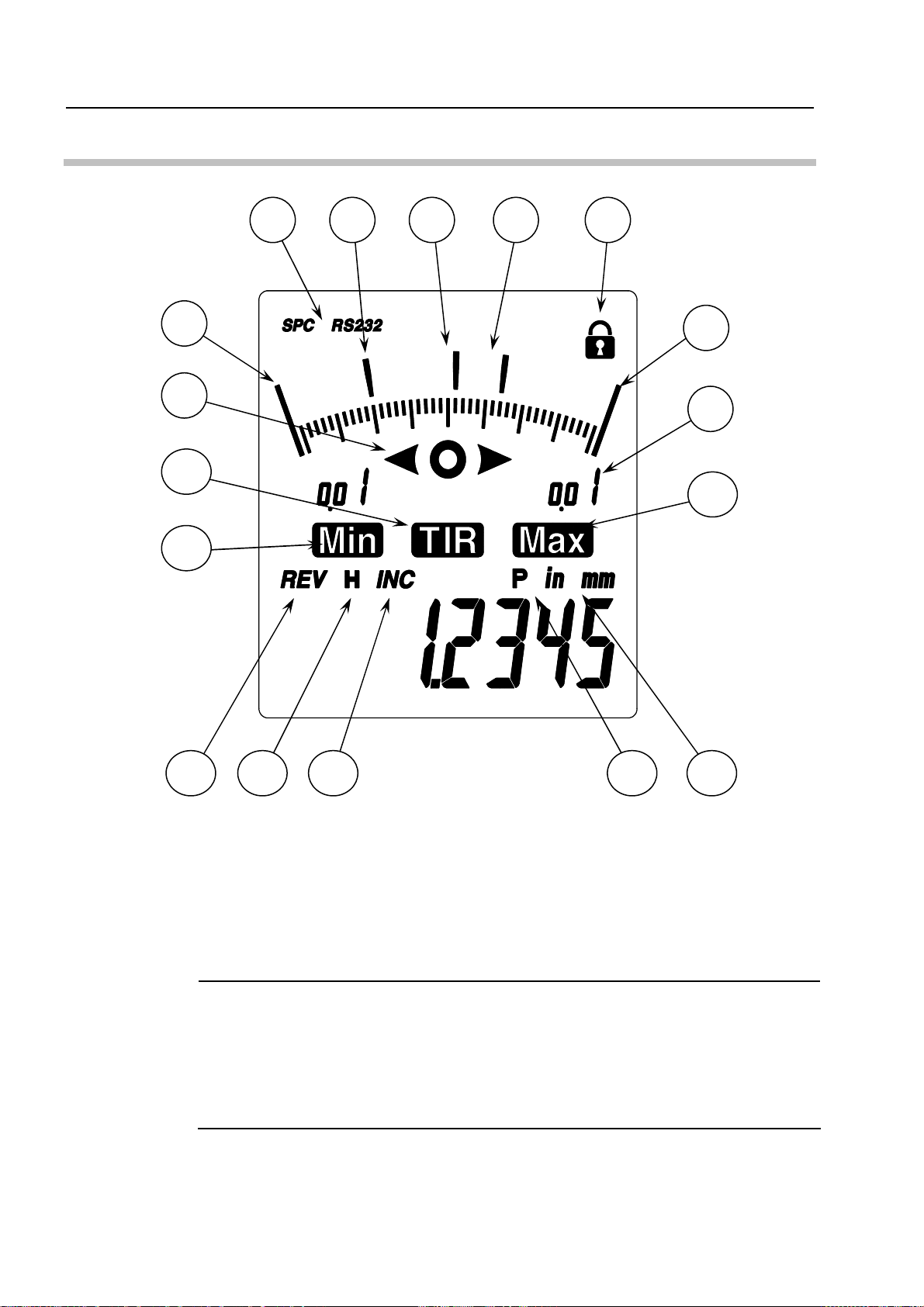

1.2 Details of the LCD Unit ................................................................................................................. 1-2

2 INSTALLATION...................................................................................................................................... 2-1

2.1 Attaching the Clamp Filter............................................................................................................ 2-1

2.2 Mounting on a Stand or a Jig....................................................................................................... 2-1

2.2 Attaching the Lifting Lever........................................................................................................... 2-1

2.3 Attaching the Release................................................................................................................... 2-2

2.4 Mounting the Lug or Special Back .............................................................................................. 2-2

2.5 Replacing the Contact Point ........................................................................................................ 2-2

3 OPERATING PROCEDURE.................................................................................................................. 3-1

3.1 Starting/Stopping This Instrument .............................................................................................. 3-1

3.1.1 Connecting to the power supply.......................................................................................... 3-1

3.1.2 Start / Stop.............................................................................................................................. 3-1

3.2 Parameter Setup Mode ................................................................................................................. 3-1

3.2.1 Switching the unit system between inch and mm during display of “unit” (only in inch spec)....3-2

3.2.2 Switching the digital resolution during display of “res.”.................................................. 3-2

3.2.3 Switching the analog range (analog resolution) during display of “range”.................... 3-3

3.2.4 Switching the count direction during display of “dir”....................................................... 3-3

3.2.5 Switching the I/O format between SPC(digimatic) and RS232 during display of “output” .......... 3-3

3.2.5.1 RS-232 setup....................................................................................................................3-3

3.2.6 Setting ID No. for RS232 communication and remote control during display of “id”.... 3-4

3.2.7 Switching the length measuring system during display of “start”.................................. 3-4

3.2.8 Returning all parameters to factory defaults during display of “reset”........................... 3-4

3.3 Measurement Mode....................................................................................................................... 3-5

3.3.1 Setting the length measuring system and reference point............................................... 3-5

3.3.1.1 INC system (Zero set) ...................................................................................................... 3-5

3.3.1.2 Preset system (setting the preset value).......................................................................... 3-5

3.3.2 Switching a measurement type in the measurement mode.............................................. 3-6

3.3.2.1 Tolerance judgment (setting/checking the upper and lower limit values)......................... 3-6

3.3.2.2 Run-out peak hold during display of “TIR” ....................................................................... 3-7

3.3.2.3 Maximum value peak hold during display of “Max”.......................................................... 3-7

3.3.2.4 Minimum value peak hold during display of “Min”............................................................ 3-8

3.3.3 Data output / Data hold.......................................................................................................... 3-9

No. 99MAH016B iii