MIURA_CONFIDENTIAL

Document No.: S827-088-4010

2

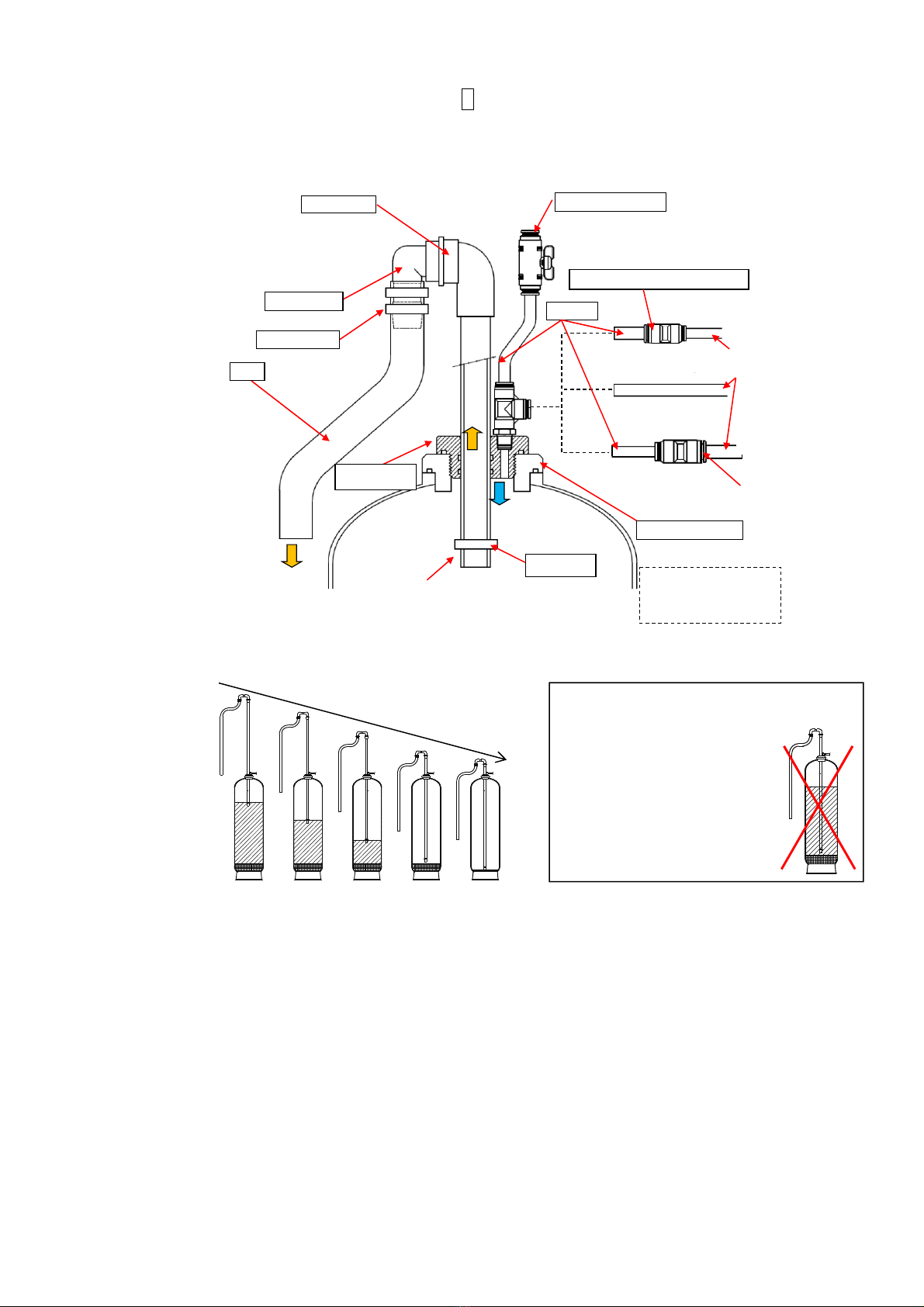

●Seal parts(If necessary)

Replace the seal parts such as O-rings together, if damage or deterioration is found.

The seal parts that could require replacement in this work are shown below.

Table 4. Seal parts with possibility of replacement

Model Seal parts with possibility of replacement Reference

page

MW-35U,65U

【Connection part of resin tank and control valve】

・O-ring Old JIS W1516 AN6227(Material:NBR)

【Tip of connection pipe ASSY(Refer to P9 figure)】

・O-ring P21(Material:NBR)

【Connection part of bypass valve and control valve】

・O-ring D=23.5mm W=2.5mm(Material:NBR)

P4,8

MW-65H~150H

MW-150C~400C

MW-100U~400U

【Connection part of resin tank and tank adaptor】

・O-ring P105(Material:NBR)

【Connection part of tank adaptor and control valve】

・O-ring AS568-349(Material:NBR)

・O-ring P65(Material:NBR)

・Backup ring for P65

P15

MW-600C/U,

1000C/U

【Connection part of resin tank】

・O-ring P185(Material:NBR) P19

Note: Refer to the parts catalog for the parts code.

2. Tools and protective equipment

●Tools, parts

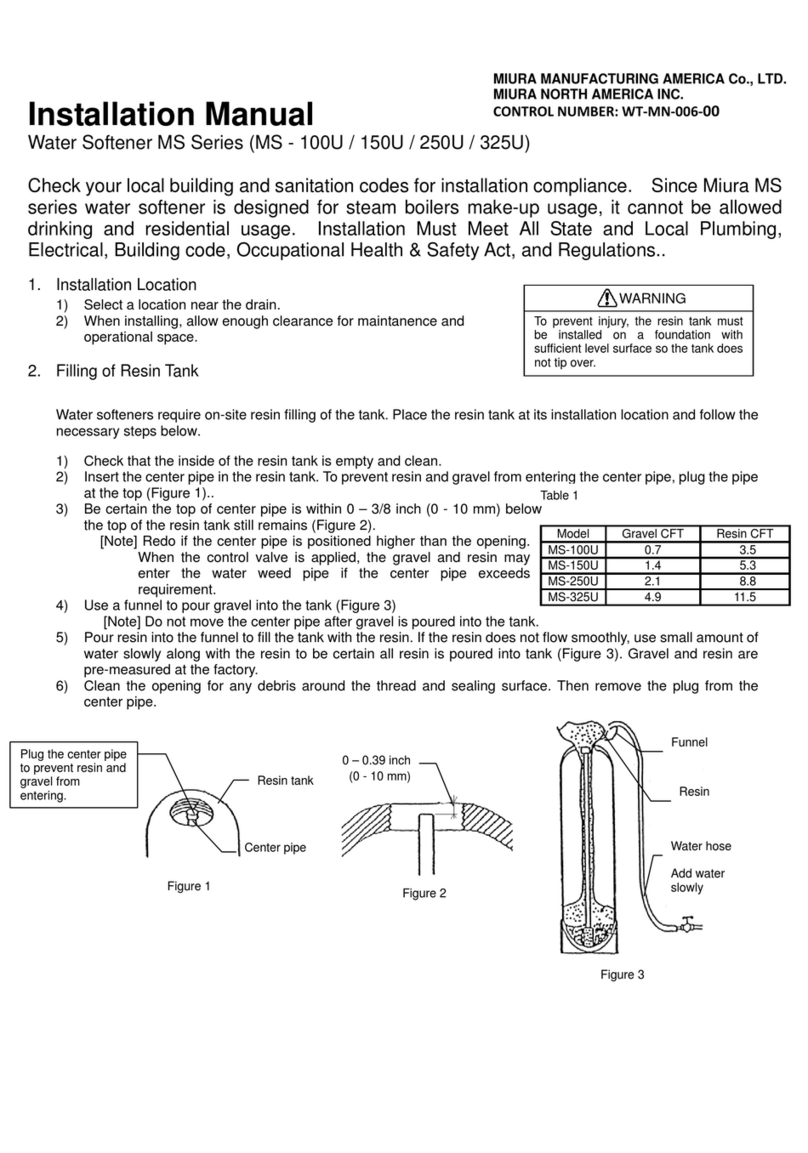

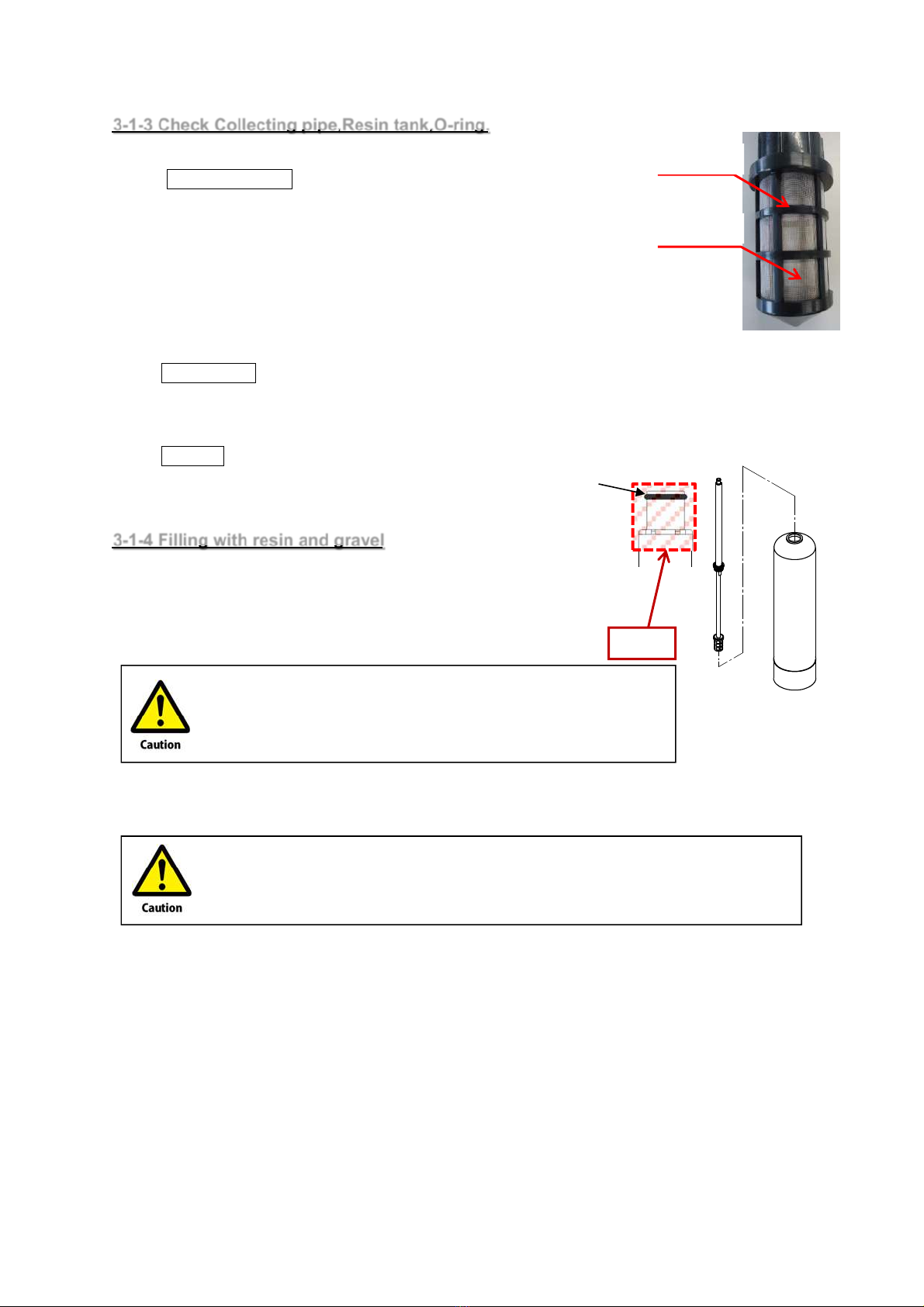

・PVC pipe 2m-2.5m about φ32 (For leveling the gravel layer after filling the gravel)

・Tank adaptor spanner (For MW-65H-150H,150C-400C,100U-400U)

CHINA, AMERICA・・・ Use the tool provided with the product. Alternatively, prepare your own tool.

KOREA・・・Japan parts code:S827-008-6101-6

• Funnel for filling the resin

For MW-35U,65U

Japan parts code:S827-001-7700-4

For MW-65H-150H, 150C-400C, 00U-400U

Japan parts code:S827-001-7800-4

・MW resin replacement kit S427-920-0010-7 (For MW-65H-150H,150C-400C,100U-400U)

*The following parts are required separately. (refer to P7)

JIS standard PVC pipe:Pipe TS VP25X2000L PVC(J140-125-2000-0)

φ16-φ12 conversion tube fitting: Different diameter tube fitting(SA27-000-0490-0)

・Resin receiving container (Tank etc.), Soil bag ,Water receiving container (Poly beaker etc.)

・Hose(If drain the resin by siphon),Commercial vacuum cleaner (Both dry and humid),Bus pump etc.

・Measuring cup (2L) ・Silicone oil ( or grease)

・Standard tool set

●Wearing of protective equipment

Depending on the work, wear a safety hat, safety glasses, safety mask, safety shoes, leather gloves,

etc.

When performing work in a high place, wear a safety belt to prevent a fall.

If necessary, arrange the funnel for filling the resin.

Resin replacement is possible without the resin

replacement kit. Work efficiency can be improved by using

resin replacement kit. Please arrange as necessary.