MFP250 / 400 / 800

Content

76609594EN-MFP-NH-V2.0.docx 3/40

Content

1General Information ............................................................................................. 5

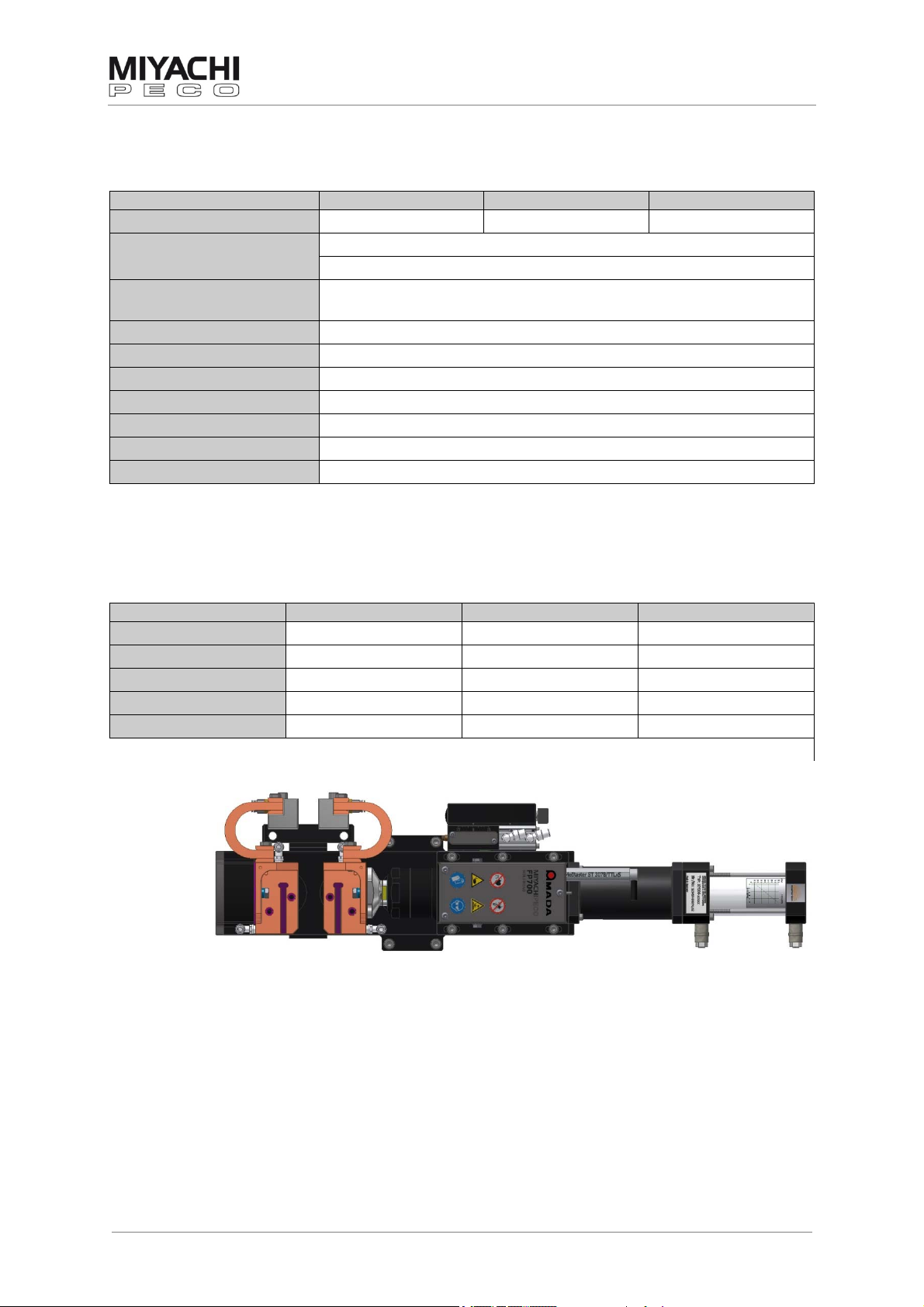

2Description Weld Heads ...................................................................................... 6

2.1Technical Data Weld Heads .............................................................................................. 6

2.2Type Overview Weld Heads .............................................................................................. 6

2.3Structure of Weld Heads and Weld Pincers .................................................................... 7

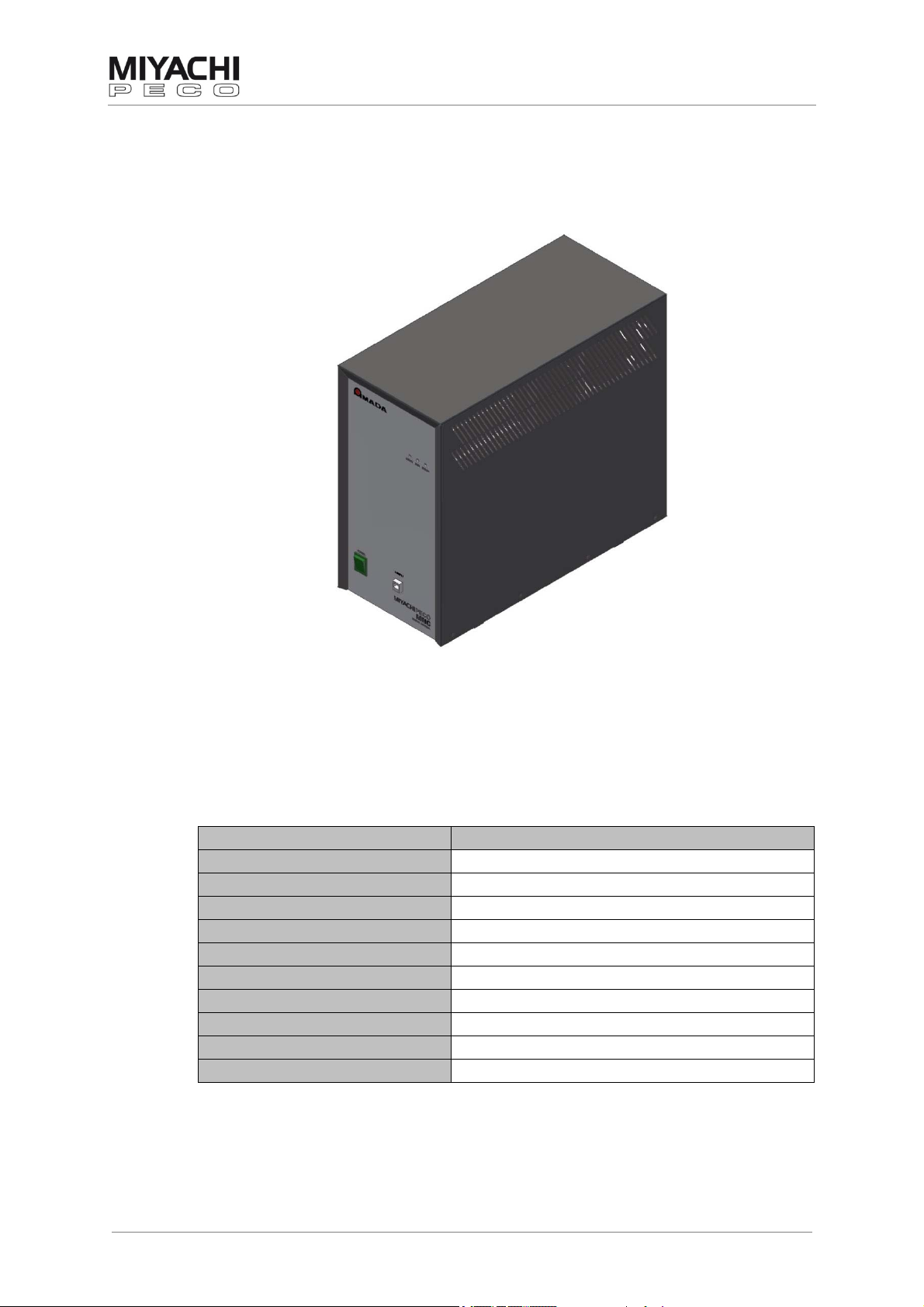

3Description Motor Head Control ........................................................................ 8

3.1Technical Data Motor Head Control ................................................................................. 8

3.2Design and Mode of Action Motor Head Control ............................................................ 9

3.2.1Rear Panel Motor Head Control .................................................................................................... 10

3.3Connector Overview MNC ............................................................................................... 12

3.3.1X6: I/O-ISQ one-axis operation ..................................................................................................... 12

3.3.2X8A: CANOPEN-IN, X8B: CANOPEN-OUT one-axis operation ................................................... 12

3.3.3X12: PROFIBUS, one-axis operation (optional) ........................................................................... 13

3.3.4X17: RS232 one-axis operation ..................................................................................................... 13

3.3.5X18: Industrial Ethernet one-axis operation (optional) ............................................................... 13

3.3.6X31: I/O-MNC OUT two-axis operation ......................................................................................... 13

3.3.7X112A, X112B, X113A, X113B: Programmable Plugs ................................................................. 14

3.3.8X112A, X112B: E/A Digital one-axis operation ............................................................................ 14

3.3.9X113A, X113B: E/A Digital two-axis operation ............................................................................ 16

3.3.10X112, X113: Default Assignment .................................................................................................. 17

3.3.11X114: ENABLE ................................................................................................................................ 20

3.3.12Plugs Motor Heads and Pincers ................................................................................................... 20

4Initial Start Up .................................................................................................... 21

4.1Electrical Connections .................................................................................................... 21

4.1.1Mains Connection .......................................................................................................................... 21

4.1.2Connecting Components .............................................................................................................. 22

4.1.3Connecting Safety Circuit (ENABLE) ........................................................................................... 2 3

4.1.4Connecting Secondary Cable ....................................................................................................... 24

4.1.5Connecting Voltage Measurement ............................................................................................... 2 5

4.1.6Connecting Locking Cylinder (Pincers only) ............................................................................... 26

4.1.7Connecting Stroke Cylinder .......................................................................................................... 26

4.1.8Connecting Proximity Switches ................................................................................................... 27

4.2Mounting Scheme ............................................................................................................ 30

4.3Initial Commissioning ...................................................................................................... 31

4.4Setup ................................................................................................................................. 31

4.4.1Setting the Electrodes ................................................................................................................... 31

4.4.2Setting the Welding Force ............................................................................................................. 31

4.5Integration in Automated Installations .......................................................................... 31

4.5.1Connection to Field Bus Systems ................................................................................................ 31