IPB-5000A

1

Table of Contents

1. Special Precautions ·········································································································1-1

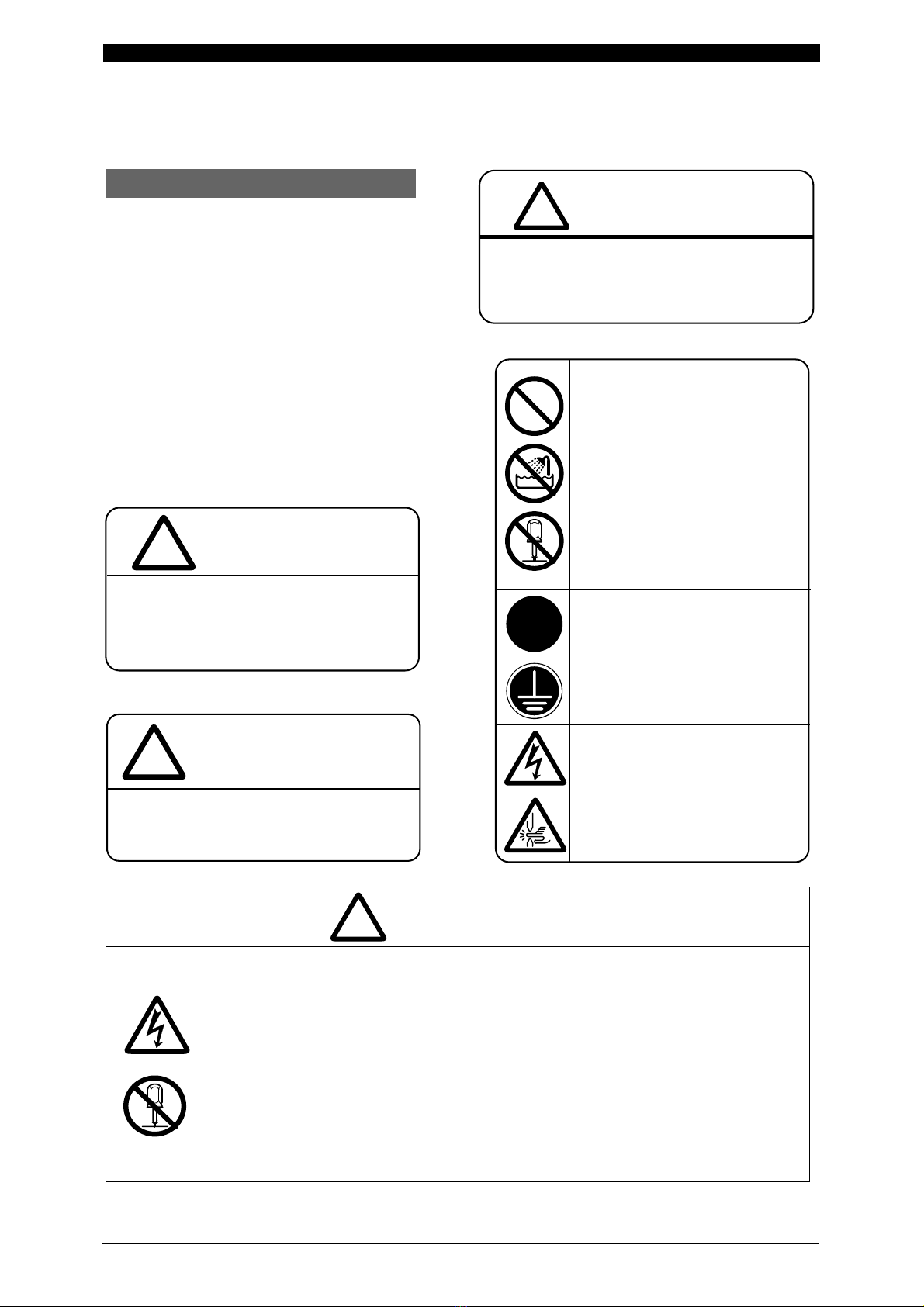

(1) Safety Precautions·······································································································1-1

(2) Precautions for Handling······························································································1-4

(3) Warning Labels for Safety···························································································· 1-5

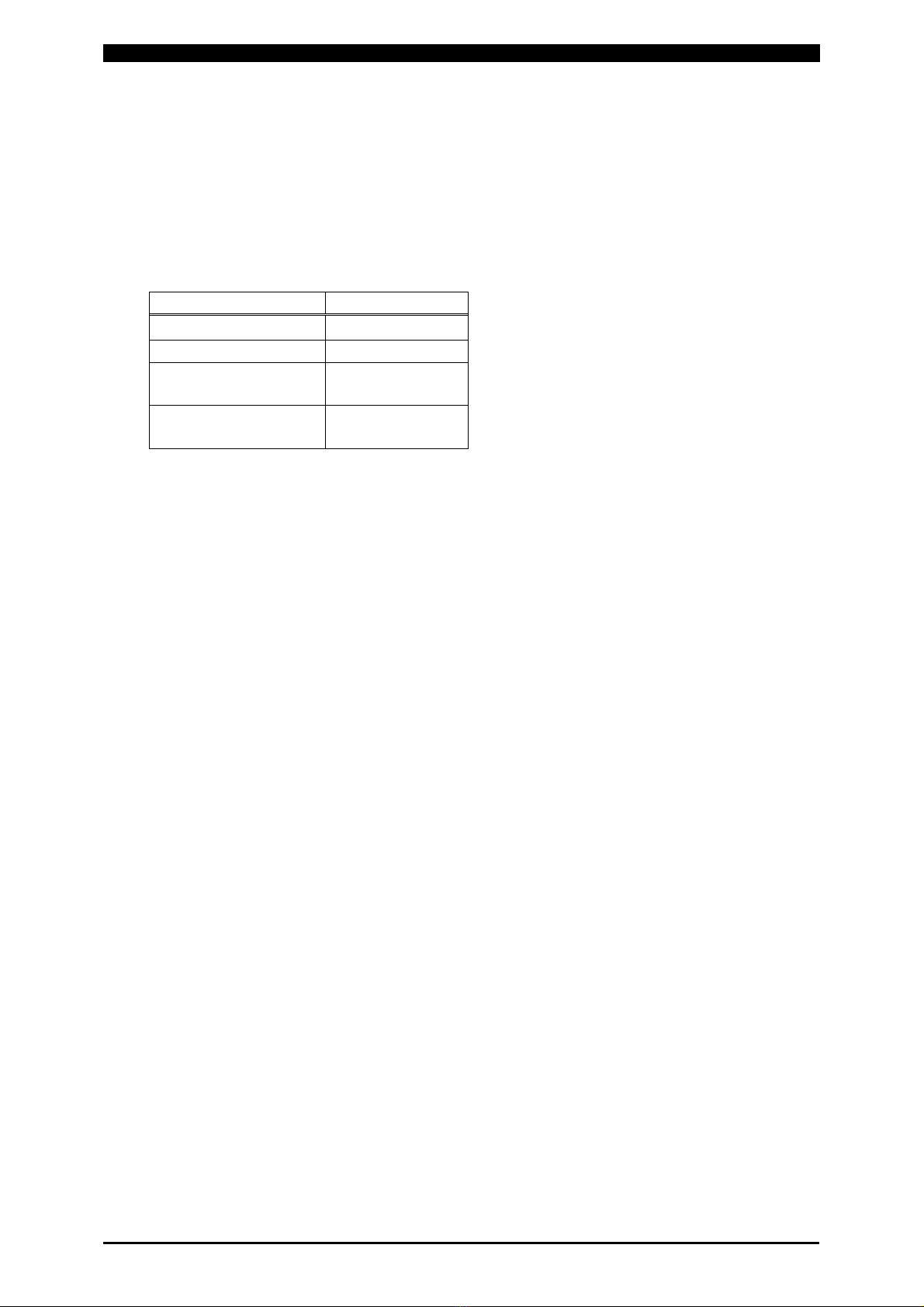

2. Features ····························································································································2-1

3. Packaging ·························································································································3-1

4. Name and Functions of Each Section············································································4-1

(1) Front Panel ··················································································································4-1

(2) Rear Panel ···················································································································4-3

5. Installation and Connection ····························································································5-1

(1) Installation····················································································································5-1

(2) Connection···················································································································5-2

6. Description of Display Screens ······················································································6-1

(1) Operation Flow·············································································································6-1

(2) MENU Screen ··············································································································6-2

(3) SCHEDULE Screen ·····································································································6-2

(4) MONITOR Screen········································································································6-5

(5) COMPARATOR Screen ······························································································· 6-7

(6) ENVELOPE Screen ·····································································································6-8

(7) PRECHECK Screen·····································································································6-12

(8) STATUS Screen ·········································································································· 6-13

①STATUS (1/2) Screen ·····························································································6-13

②STATUS (2/2) Screen ·····························································································6-14

③ERROR SETTING Screen ······················································································6-16

④MISC Screen ··········································································································· 6-16

7. Basic Operation················································································································7-1

8. External Interface ·············································································································8-1

(1) Connection Diagram for External Input/Output Signals ···············································8-1

①When contacts on PLC are used as input signal ····················································8-1

②When NPN transistor (sink type) on PLC is used as input signal ··························· 8-2

③When PNP transistor (source type) on PLC is used as input signal ·······················8-3

④When solenoid valves are activated by the use of an external power supply·········8-4

⑤When solenoid valves are activated by the use of an internal power supply··········8-4

(2) External Input/Output Signals ······················································································8-4

(3) Schedule No. and Schedule Select Terminals····························································· 8-8