RECEIVING AND STORAGE

Receiving Inspection

Upon receipt, and at the time of actual unloading, each

package should be visually inspected for any possible

damage or electrolyte leakage. If either is evident, a

more detailed inspection of the entire shipment should

be conducted and noted on the bill of lading. Record

receipt date, inspection data and notify carrier of any

damage.

Unpacking

1. Always wear eye protection.

2. Check all batteries for visible defects such as cracked

containers, loose terminal posts, or other unrepairable

problems. Batteries with these defects must be replaced.

3. Check the contents of the package against the packaging

list. Report any missing parts or shipping damage to your

MK Battery agent or MK Battery immediately.

4. Never lift batteries by the terminal posts.

5. Always lift batteries by the bottom or use the lifting handles.

Storage

1. Batteries should be stored indoors in a clean, level, dry

and cool location. Recommended storage temperature is

0°F to 90°F (– 18°C to 32°C).

2. Stored lead-acid batteries self discharge and must be

given a charge six months from date of manufacture to

prevent permanent performance degradation. Record

dates and conditions for all charges during storage.

3. Recommended charge during storage is at a constant

voltage of 13.80V (6.90V for 6V battery) for 24 hours at

77°F (25°C).

4. Do not store beyond 12 months.

INSTALLATIONS

General

Caution should be taken when installing batteries to

insure no damage occurs. The battery cabinet, tray, rack,

etc. shall be inspected for sharp edges that could cause

damage to the battery casing. Batteries shall not be

dropped, slid, placed on rough or uneven surfaces such

as tray lips or grated flooring. Mishandling of batteries

could result in equipment damage or human injury.

MK Battery will not be liable for damage or injury as a

result of mishandling or misuse of the product.

Grounding

When grounding the battery system, proper techniques

should be applied per electrical standards, such as NEC

and/or local codes, as well as User Manual of specific

application.

BATTERY ASSEMBLY

(Always wear eye protection.)

1. Set up the batteries so that the positive post (+) of one

battery is connected to the negative post (–) of the next

battery for all series connections.

2. All battery electrical contact surfaces shall be cleaned by

rubbing gently with a non-metallic brush or pad before

installing connectors. No-Ox-ID grease can be used but

is not required.

BATTERY ASSEMBLY

(con’t)

3. Install all electrical connectors / cables and bolting hard-

ware loosely to allow for final alignment of batteries.

Torque to manufacturer recommendations.

4. After torquing, read the voltage of the battery string to

ensure the individual batteries are connected correctly.

The total voltage should be approximately equal to the

number of batteries times the measured voltage of one

battery (when connected in series). If the measurement

is less, recheck the connections for proper voltage and

polarity.

5. Read and record connection resistance and note the

method of measurement. This helps determine a satis-

factory initial installation and can be used as a reference

for future maintenance requirements. See Appendix B,

recording forms, in the back of the manual. Clean,

remake and remeasure any connection having a

resistance measurement greater than 10% of the

average of all the same type of connections.

6. Battery performance is based on the output at the battery

terminals. Therefore, the shortest electrical connections

between the battery system and the operating equipment

results in maximum total system performance.

Cable size selection should be determined by current

carrying requirements as well as providing a minimum

voltage drop between battery system and operation

equipment. Proper techniques should be applied per

electrical standards, such as NEC and/or local codes.

Note: Excess voltage drop will reduce the support

time of the battery system.

SYSTEM OPERATION

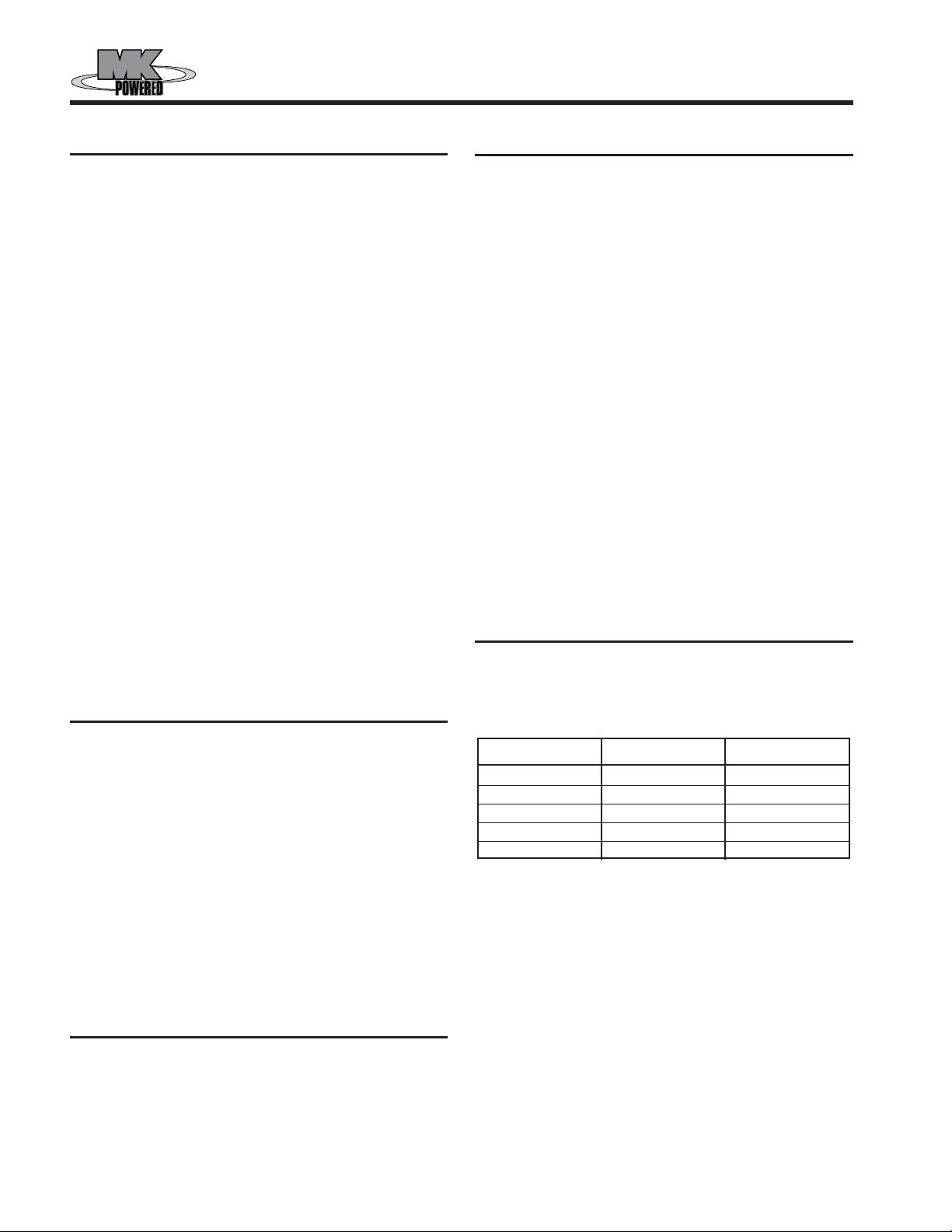

State of Charge

Battery state of charge can be determined by measuring

the open circuit voltage. Consult the below table.

NOTE: Divide values in half for 6-volt battery(ies)

*The “true” O.C.V. of a battery can only be determined

after the battery has been removed from the load (charge

/ discharge) for 24 hours.

Charging

Consult Charger User Manual of specific application

for Safety and Operating requirements.

For cyclic applications it is important that the battery(ies)

be charged fully after each discharge. It is recommended

that 108% to 115% of the Ah (Amp Hour) capacity

removed from the battery(ies) be replaced after each

discharge. This additional Ah is to compensate for

any efficiency losses between the battery charger and

the battery(ies)

% Charge Gel AGM

100 12.85 or higher 12.80 or higher

75 12.65 12.60

50 12.35 12.30

25 12.00 12.00

0 11.80 11.80

State of Charge vs. Open Circuit Voltage*

®