Index:

CE Declaration of conformity:...................................................................................................................................................................................1

Electrical connection to the grid:.............................................................................................................................................................................4

Description:...................................................................................................................................................................................................................4

Characteristics:............................................................................................................................................................................................................4

User instructions:........................................................................................................................................................................................................5

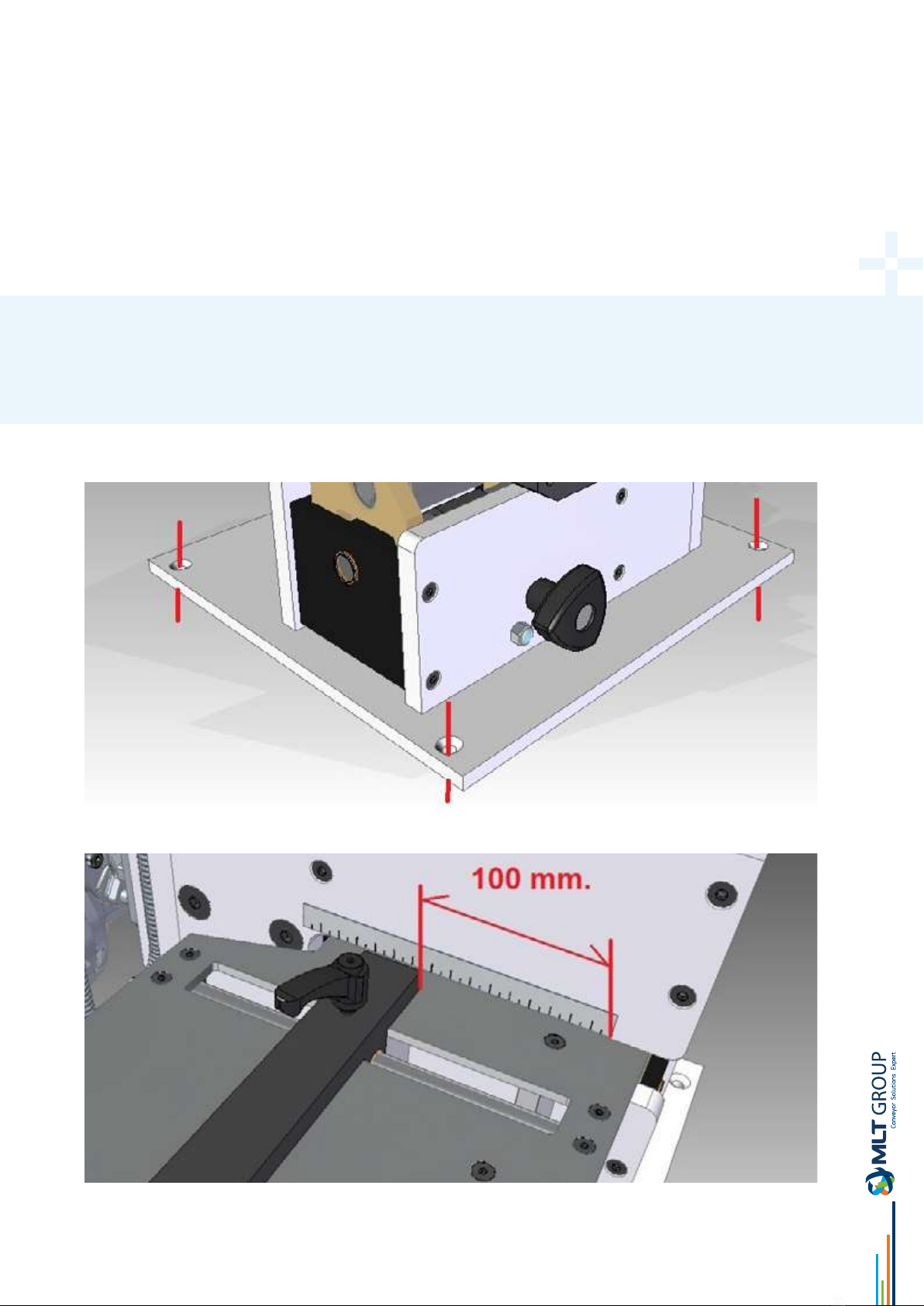

Changing and adjusting the blade:..........................................................................................................................................................................6

Stroke adjustment of rollers:...................................................................................................................................................................................8

Electrical diagram:....................................................................................................................................................................................................10

Parts list:.....................................................................................................................................................................................................................10