10

Locate the battery clip. Connect the red wire to the positive-switch lug of the DC power jack.

Connect the black wire to the ring lug of the input jack. Solder both connections now.

Connect a 2N5088 transistor to #11, #10, and #9. Make sure the

flat side of the transistor is facing up with the body pointing towards

the footswitch. The orientation must match drawing 7. Solder

connections on #11 and #9 now.

#9: Emitter

#10: Base

#11: Collector

2N

5088

EBC

SECTION 8

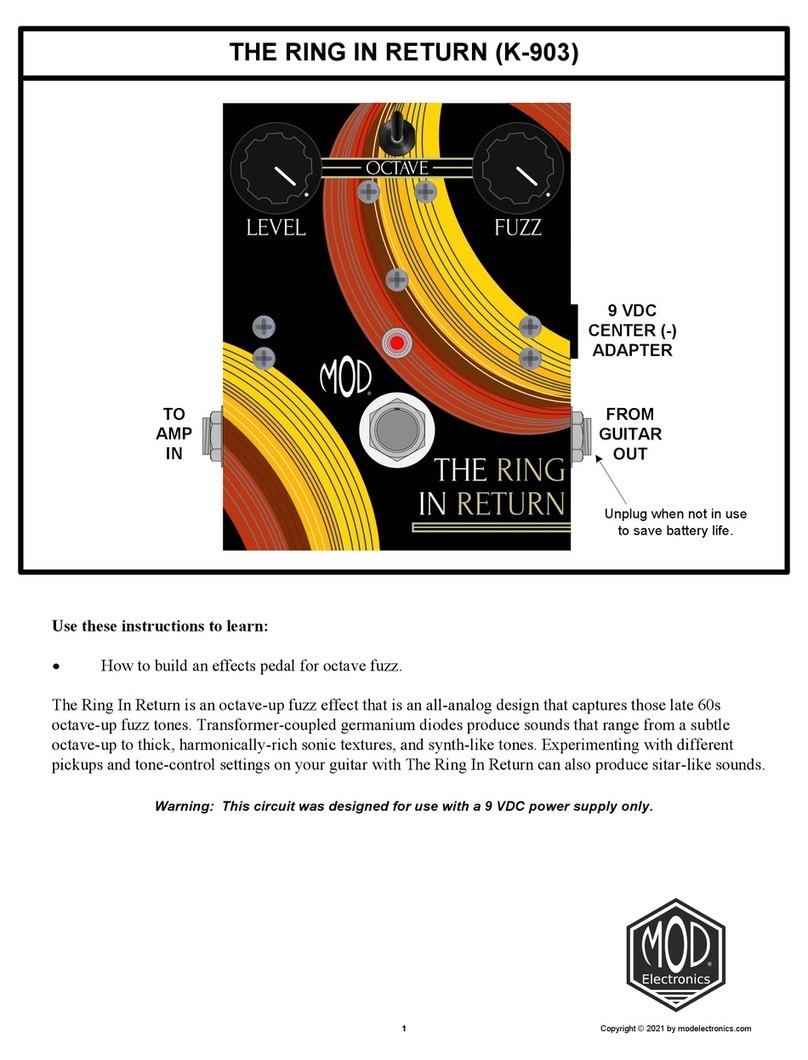

Attach the knobs provided to the potentiometer shafts. Install a 9 volt battery, close the cover using

the screws provided (battery not required when using 9v DC power supply). Plug a guitar into input

jack on right. This turns the unit on. Plug a cable into output jack and plug it into your amplifier.

-Unplug from the input jack of the unit to turn it off and save power.

It’s always a good idea to thoroughly double-check your connections before applying power.

Connect a 0.01µF capacitor from #5 to #14.

Connect a 0.01µF capacitor from #14 to #12.

Connect a 1M resistor from #5 to #6.

Connect a 1M resistor from #12 to #11.

SECTION 7

Please refer to DRAWING 8.

Connect a 2N5088 transistor to #16, #15, and #14. Make sure the

flat side of the transistor is facing down with the body pointing

towards the footswitch. The orientation must match drawing 8.

Solder connections on #16, #15, and #14 now.

#16: Emitter

#15: Base

#14: Collector

2N

3906

CBE

Connect a diode from #5 to #7 with the black band connecting to #5. Solder connection at #5 now.

Connect a diode from #12 to #10 with the black band connecting to #12. Solder both connections now.

Connect a 2N5088 transistor to #6, #7, and #8. Make sure the flat

side of the transistor is facing down with the body pointing towards

the pots. The orientation must match drawing 8. Solder

connections on #6, #7, and #8 now.

#6: Emitter

#7: Base

#8: Collector

2N

3906

C B E

black band

SECTION 6

Please refer to DRAWING 7.

Connect a 2N5088 transistor to #1, #2, and #3. Make sure the flat

side of the transistor is facing up with the body pointing towards

the pots. The orientation must match drawing 7. Solder

connections on #1, #2, and #3 now.

#1: Emitter

#2: Base

#3: Collector

2N

5088

E B C

SECTION 5

Please refer to DRAWING 6.

Connect a 330pF capacitor from #7 to #11.

Connect a 330pF capacitor from #6 to #10. Be careful not to short these two capacitors.

Connect the 680k resistor from #19 to lug 1 of the left 100KA pot. Solder both connections now.

Connect a 240k resistor from #22 to lug 1 of the right 100KA pot. Solder both connections now.

1 2 3 4 5 6 7 8

14 13 12 11 10 91516

18 19 20 21 22 23 2417

123

Finishing Up