Page 5 of 6

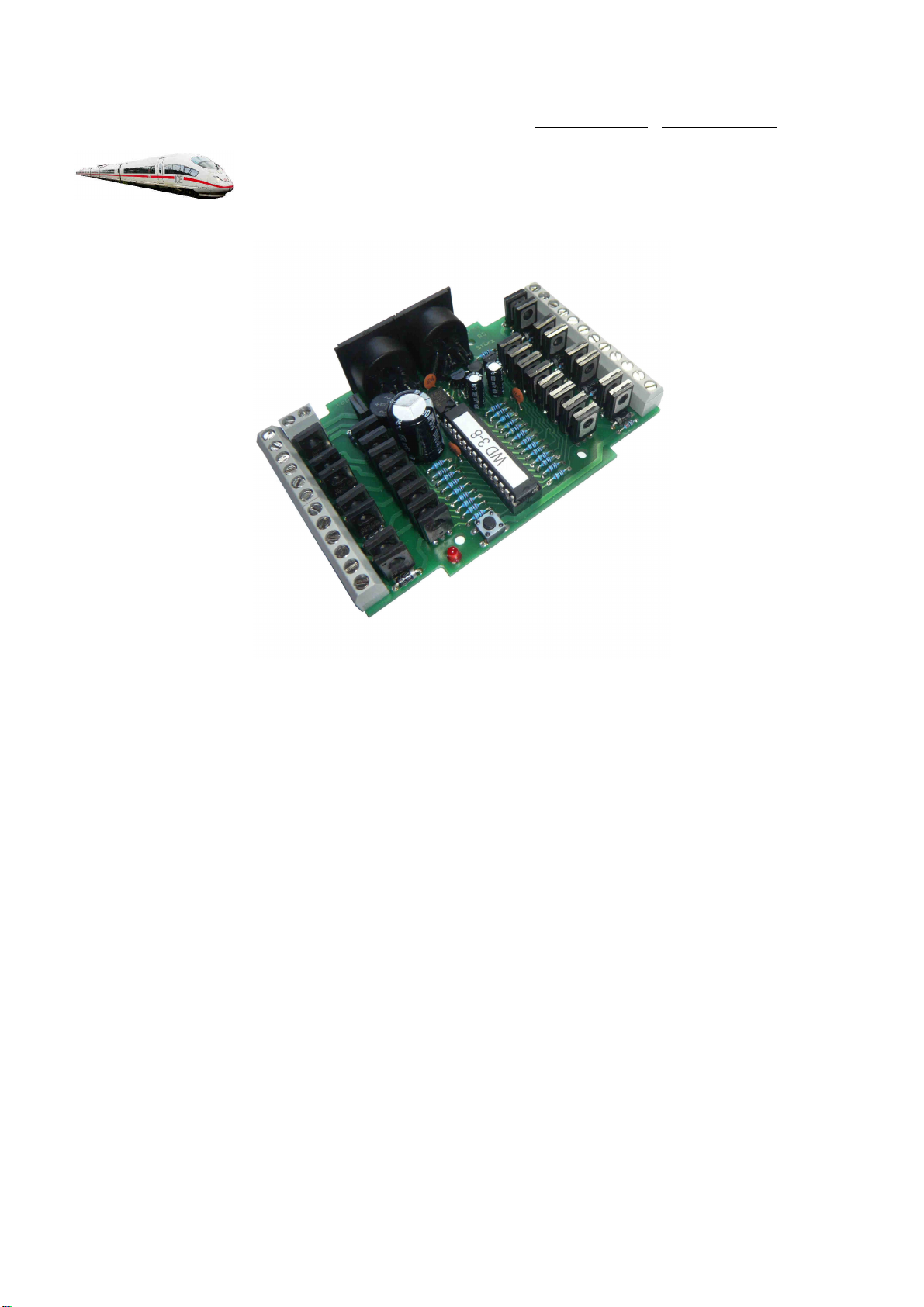

Connection of motorized turnouts

When connecting motorized turnouts, the

extension kit ESMot must be populated (for

the concerned outputs). Basically the connec-

tion of all motorized turnouts is the same: Both

contacts of the motor are directly connected to

the outputs of the Accessory Decoder

WDMiba, each at terminals a and c – terminal

b is left unconnected.

Some vendors of motorized turnouts equip their motors with an

additional circuitry (in most cases two diodes) which leads to more

than just two contacts. Usually there is one common ground (or

voltage supply) which is to be connected to terminal a. Additionally

there should be a contact for each turning direction which are to be

both connected to terminal c. There might be further wires but they

are not of interest for the connection to the Accessory Decoder

WDMiba.

Parameters and Programming

Programming

By programming the address of this module and all further pa-

rameters are set. In this section all parameters are explained.

Refer to the last page of these instructions for an example for the

programming procedure.

Convention Bit and Key

In information technology “Bit 0” to “Bit 7” is common.

For model railroaders a numbering of “bit 1” to “bit 8” is much more

convenient, as “Bit 1” becomes equal to “Key 1” or “position 1”.

This convention is used in these instructions.

Overview of parameters

Address 0: Address of this module 1 to 103 / 111 (80)

see table of addresses

Address 1: Timer assignment):

Bit value 0 (Off, “0” or “-“) assigns timer 1

Bit value 1 (On, “1” or “/”) assigns timer 2

Address 2: Timer 1 1 to 254, 255 (16)

Pulse length: 1 to 254: (80ms increments)

Continuous current: 255 (all bits 1)

Factory setting: 16 = pulse length 1.2 seconds.

Address 3: Timer 2 1 to 254, 255 (255)

Pulse length: 1 to 254: (80ms increments)

Continuous current: 255 (all bits 1)

Factory setting: 255 = continuous current

Address of this module

The address of this module can be set to any value in the range

from 1 to 111. Note that at certain central units addresses 104 to

111 are reserved for internal purposes during operation and should

thus not be used.

Also, addresses 0 to 3 are often used for programming parameters

of modules. Therefore these addresses should also not be used.

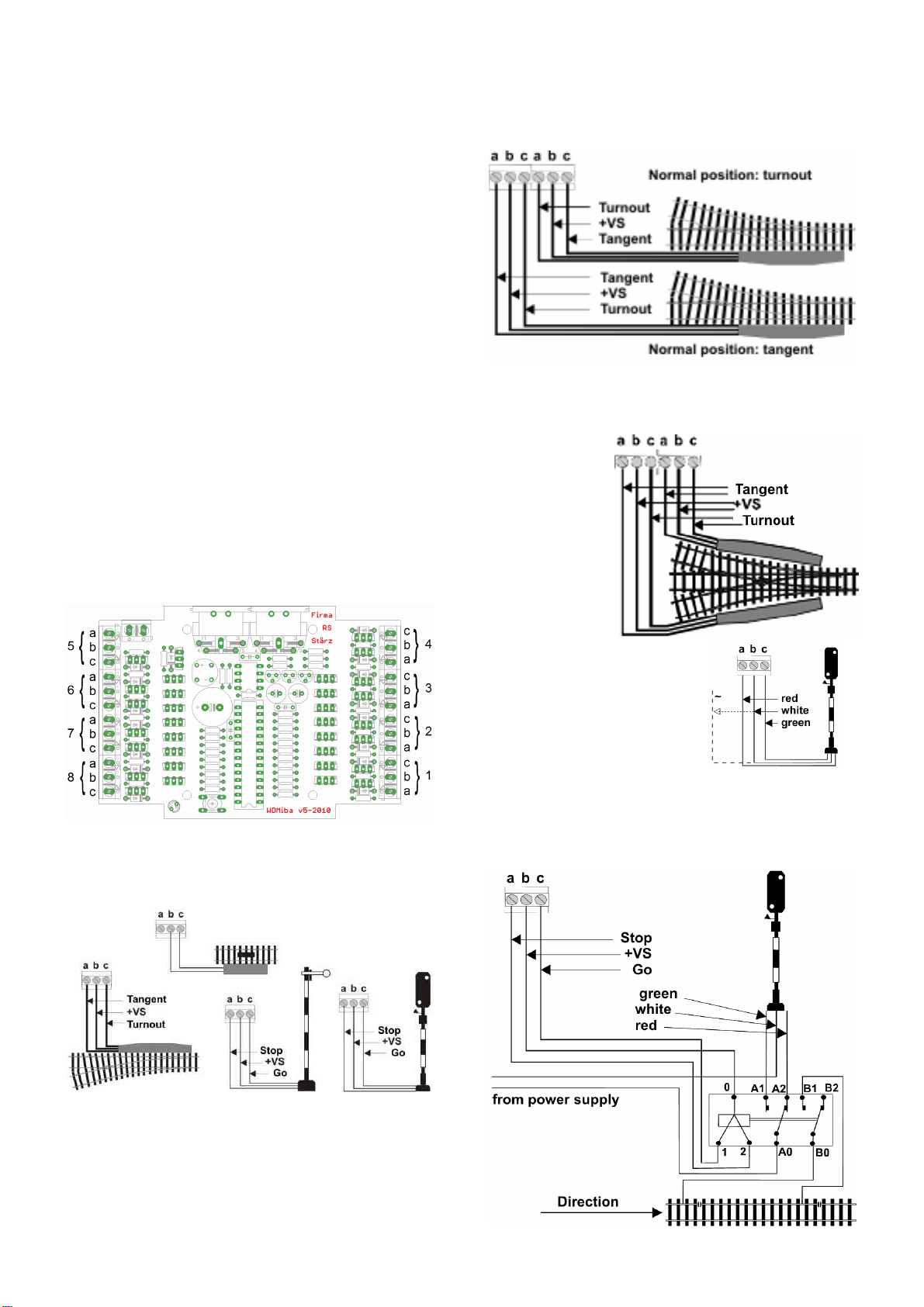

Operation mode

The Accessory Decoder WDMiba offers 2 operation modes:

Pulsed current and continuous current.

To allow controlling accessory types with different current require-

ments, for each of decoder’s eight output channels one of two

timers can be selected individually. Both timers (1 and 2) can have

either a pre-determined pulse length value or set to continuous

current.

Operation mode pulsed current

The operation mode pulsed current enables the output current only

for a specific time (set by the timer) after switching to this direction.

Afterwards, the output is off.

Not all solenoid powered accessories have the same requirements

for the duration of pulsed current to operate them. For instance, a

turnout with a double solenoid and limit stop can usually be oper-

ated with a 0.5 to 1 second pulse length. Theoretically it is possible

to operate this type of turnout with continuous current, but if the

limit stop is not working, the solenoid will get damaged. Solenoid

turnouts without limit stop should be controlled with pulses lasting

0.2 to 0.5 seconds.

On the other hand, there are slowly moving turnouts and sema-

phore signals. These might require pulse lengths of 4 to 8 sec-

onds.

Uncoupler tracks should as well not be operated with continuous

current. Instead, select a pulse with a length of up to 20 seconds

for uncouplers.

Operation mode continuous current

The operation mode continuous current enables the output current

permanently, so one of the dual-port outputs is always active.

For a light signal an output of continuous current is required which

lights up red on Stop but lights up green on Go instead. Only one

of the two lights is activated at the same time.

Timers 1 and 2

Both timers of the Accessory Decoder WDMiba are equal which

means that they can be programmed independently to any pulse

length between 0.08s (80ms) and 20 seconds with 80ms incre-

ments, by selecting values from 1 to 254. Both timers can also be

set to identical pulse lengths or continuous current mode (by pro-

gramming value 255).

For each of the 8 decoder output channels one of those 2 timers is

assigned.

Timer 1 is assigned for all output channels where operation mode

0 is selected; timer 2 is assigned for all output channels where

operation mode 1 is selected, respectively.

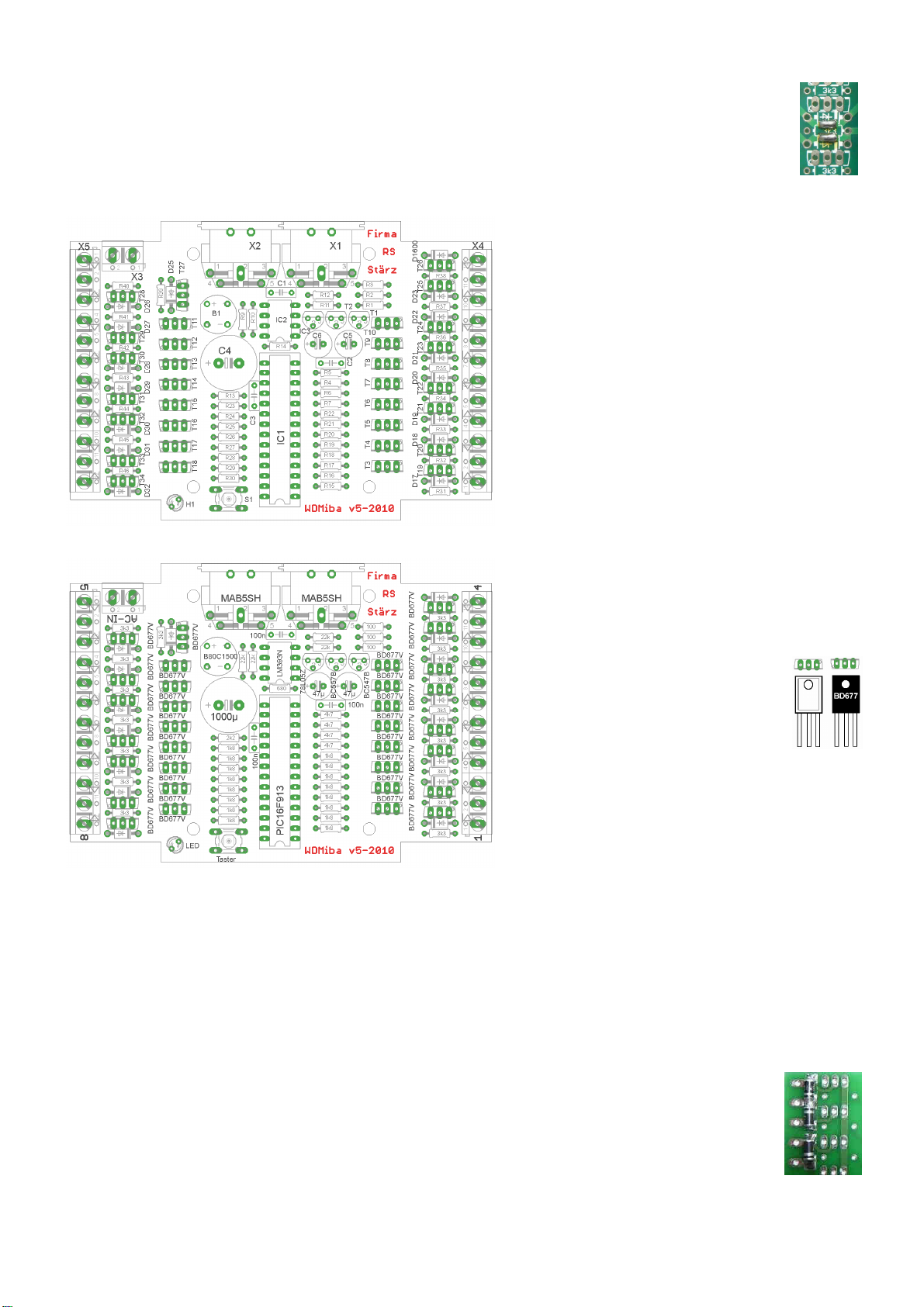

Overview of timers

The pulse length is calculated by summation of the separate bit

values (1 to 254) multiplied with the increment (0.08 s = 80 ms)

Bit 1 2 3 4 5 6 7 8

Value 1 2 4 8 16 32 64 128

Pulse 0,08 0,16 0,32 0,64 1,28 2,56 5,12 10,24

Value 255 (all bits ON) selects continuous current.

On the next page you’ll find a table with some examples.

Delayed output

In computer controlled and other automatic layouts several turn-

outs or signals are typically switched simultaneously. This could

result in excessive power consumption which exceeds the output

capacity of the decoder.

To prevent problems due to current peaks decoder outputs config-

ured for pulse type outputs are activated with 80 ms delay between

them when operated simultaneously. For channels set to continu-

ous current output, there is no delay between them in simultane-

ous operation.

Security monitoring system

Poorly laid wiring or malfunctions of system components may

result in a situation where a pulse type output is not switched off in

time. This can cause overheating or even burn a solenoid con-

nected to decoder output.

The Accessory Decoder WDMiba is equipped with a security

monitoring system (Watchdog) which cuts off the output current of

all output channels after about 2 seconds when an output pulse is

not terminated in time normally due to SX system malfunctions.

Factory default settings

Address of this module: 80

Operation mode: 0 0 0 0 0 0 0 0

(all output channels use timer 1)

Timer 1: 16 (1.28 seconds)

Timer 2: 255 (continuous current output)

If the address of this module is set to a value greater than 111, it

will be reset to the factory default setting (90).

Setting the address of this module to the value of 255 will reset all

parameters to their factory default settings.

Revert back to previous settings

Entering 0 as address, response or dropout delay reverts the

corresponding value to its previously programmed one.