2

INDEX

1 SAFETY INSTRUCTIONS .........................................................................................................4

1.1 Safety Warnings found in this Manual............................................................................4

1.2 Safety Warnings (Equipment)..........................................................................................4

2 INTRODUCTION........................................................................................................................5

2.1 MOGK's QUALITY POLICE...............................................................................................5

2.2 MOGK's Costumers ..........................................................................................................5

2.3 About the Equipment........................................................................................................ 6

2.4 About the manual..............................................................................................................6

3 GENERAL GUIDELINES...........................................................................................................6

3.1 Receiving, Verifying and Storing.....................................................................................6

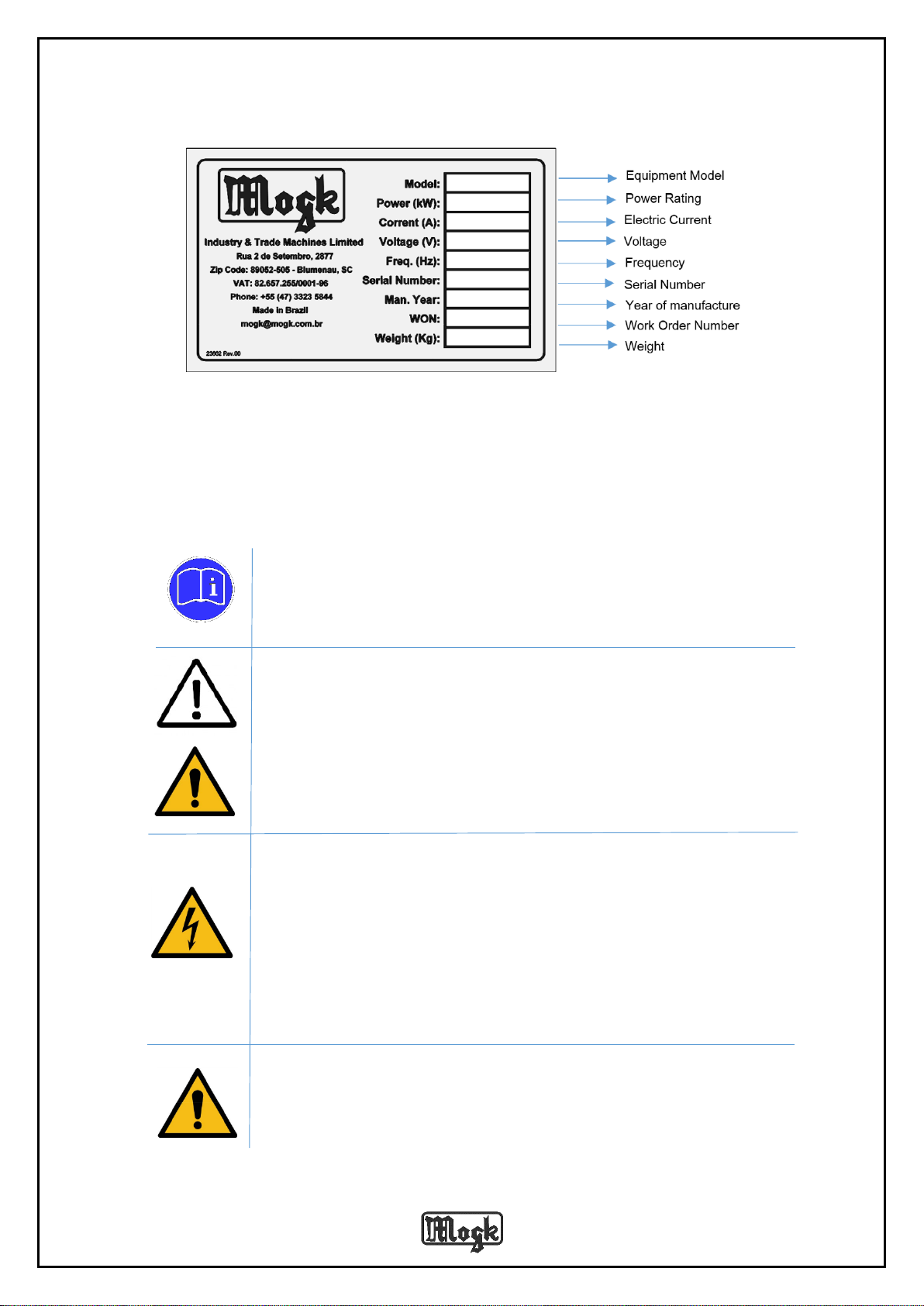

3.2 Identification......................................................................................................................6

4 INSTALLING..............................................................................................................................7

5 COMPRESSED AIR NETWORK CONDITIONS.......................................................................8

5.1 Pneumatic Conexions –Regulating Filter......................................................................8

6 SAFETY (MACHINE).................................................................................................................8

7 OPERATION..............................................................................................................................9

7.1 Operating warning ..........................................................................................................10

7.2 Operating Procedures ....................................................................................................10

7.3 Speed and Pressure Control..........................................................................................11

7.4 Digital Controller –Setting Parameters........................................................................12

8 SECURITY ADHESIVE SIGNS................................................................................................13

9 MAINTENANCE.......................................................................................................................14

9.1 Cleaning...........................................................................................................................14

9.2 Spare Parts ......................................................................................................................14

9.3 Technical Assistance .....................................................................................................15

10 TECHNICAL DATA AND INFORMATION ............................................................................16

11 Pneumatic Scheme ..............................................................................................................17

12 Electric Scheme....................................................................................................................18

12.1 Electric diagram –biphasic 220V................................................................................18

12.2 Electric diagram –three-phase 220V..........................................................................19

12.3 Electric diagram –three-phase 380V..........................................................................20

13 ASSEMBLY DRAWINGS AND SPARE PARTS...................................................................21

13.1 Parts list.........................................................................................................................21

13.2 General Set....................................................................................................................23