2

SUMMARY

1 SECURITY INSTRUCTIONS .....................................................................................................3

1.1 Safety Warnings in the Manual Contents.......................................................................3

1.2 Security Warnings on the Equipment.............................................................................3

2 INTRODUCTION........................................................................................................................ 4

2.1 Mogk Quality Policy.......................................................................................................... 4

2.2 Mogk Customers...............................................................................................................4

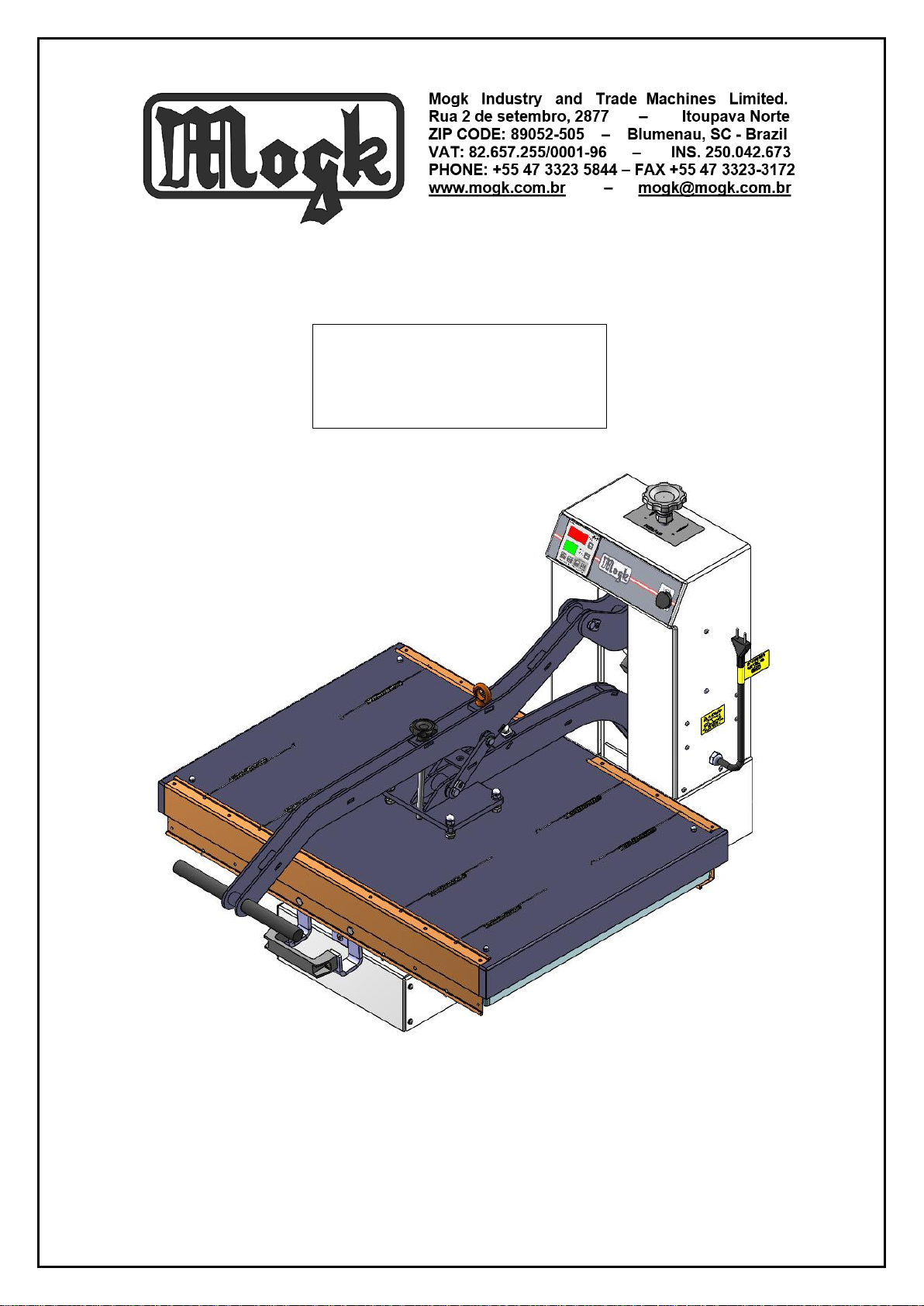

2.3 About the Equipment........................................................................................................4

2.4 About Manual ....................................................................................................................5

3 GENERAL INFORMATIONS..................................................................................................... 5

3.1 Receipt and verification ...................................................................................................5

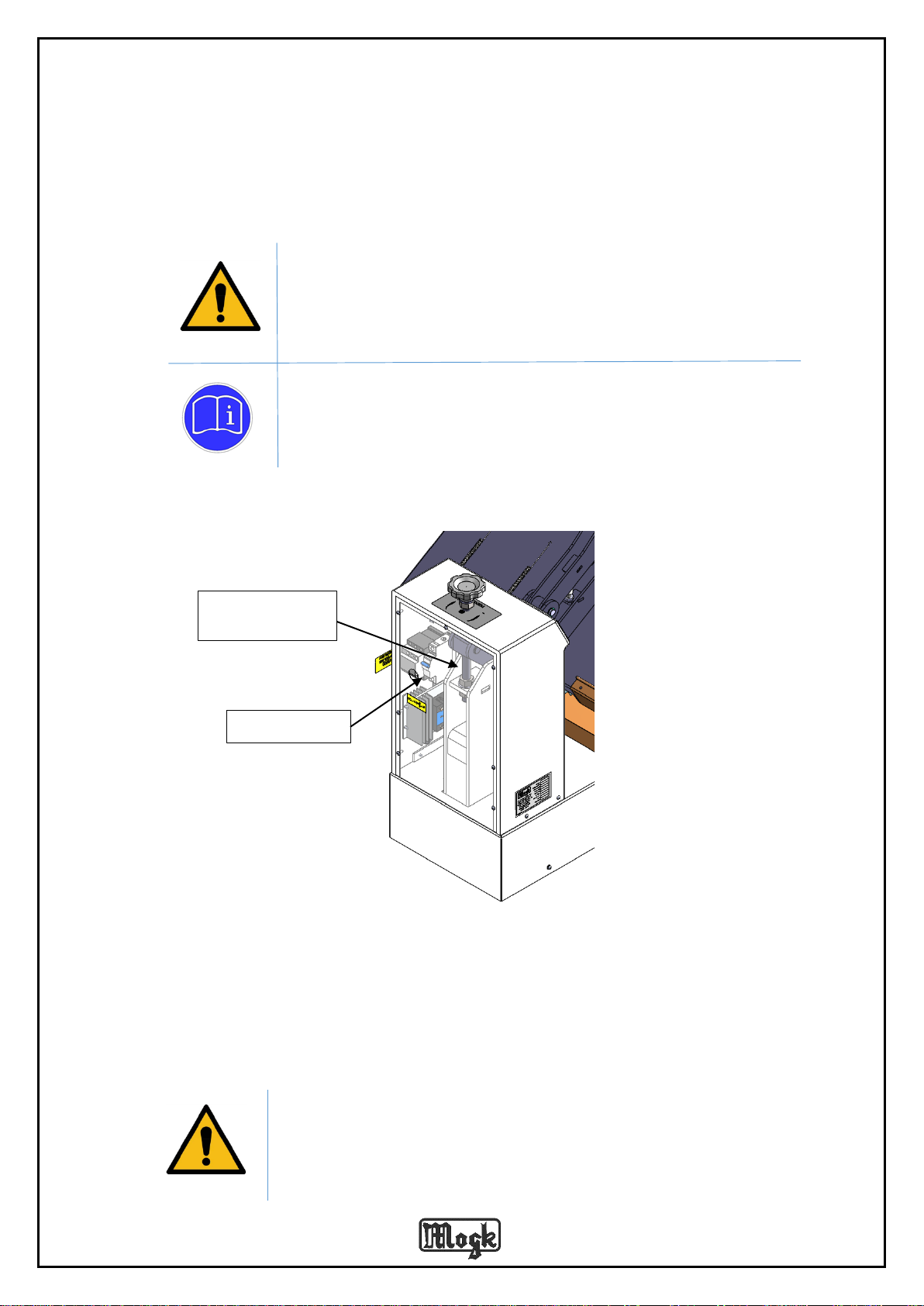

3.2 Identification......................................................................................................................5

4 INSTALLATION.........................................................................................................................6

4.1 Operation of machine.......................................................................................................6

4.2 Pressure Control...............................................................................................................7

4.3 Control Panel - Programming Parameters .....................................................................7

5 MAINTENANCE......................................................................................................................... 9

5.1 Cleaning.............................................................................................................................9

5.2 Spare parts ........................................................................................................................9

5.3 Technical assistance......................................................................................................10

6 TECHNICAL DATA AND INFORMATION ..............................................................................11

7 ELECTRICAL SCHEMATIC....................................................................................................12

8 ASSEMBLY DRAWINGS AND SPARE PARTS.....................................................................13

8.1 PTM -80 With Top Platen Heating..................................................................................13

8.1.1 Parts list.....................................................................................................................14

8.1.2 Top platen assembly..................................................................................................18

8.1.3 Lower platen assembly..............................................................................................19

8.2 PTM-80 With Lower Platen Heating...............................................................................20

8.2.1 Top platen assembly..................................................................................................20

8.2.2 Lower plate assembly................................................................................................21

9 CERTIFICATE OF WARRANTY.............................................................................................. 23

10 APPENDIX.............................................................................................................................24

11 MOGK PRODUCTS............................................................................................................... 25