2

SUMMARY

1 SECURITY INSTRUCTIONS .....................................................................................................3

1.1 Safety Warnings in the Manual Contents.......................................................................3

1.2 Security Warnings on the Equipment.............................................................................3

2 INTRODUCTION........................................................................................................................4

2.1 Mogk Quality Policy..........................................................................................................4

2.2 Mogk Customers...............................................................................................................4

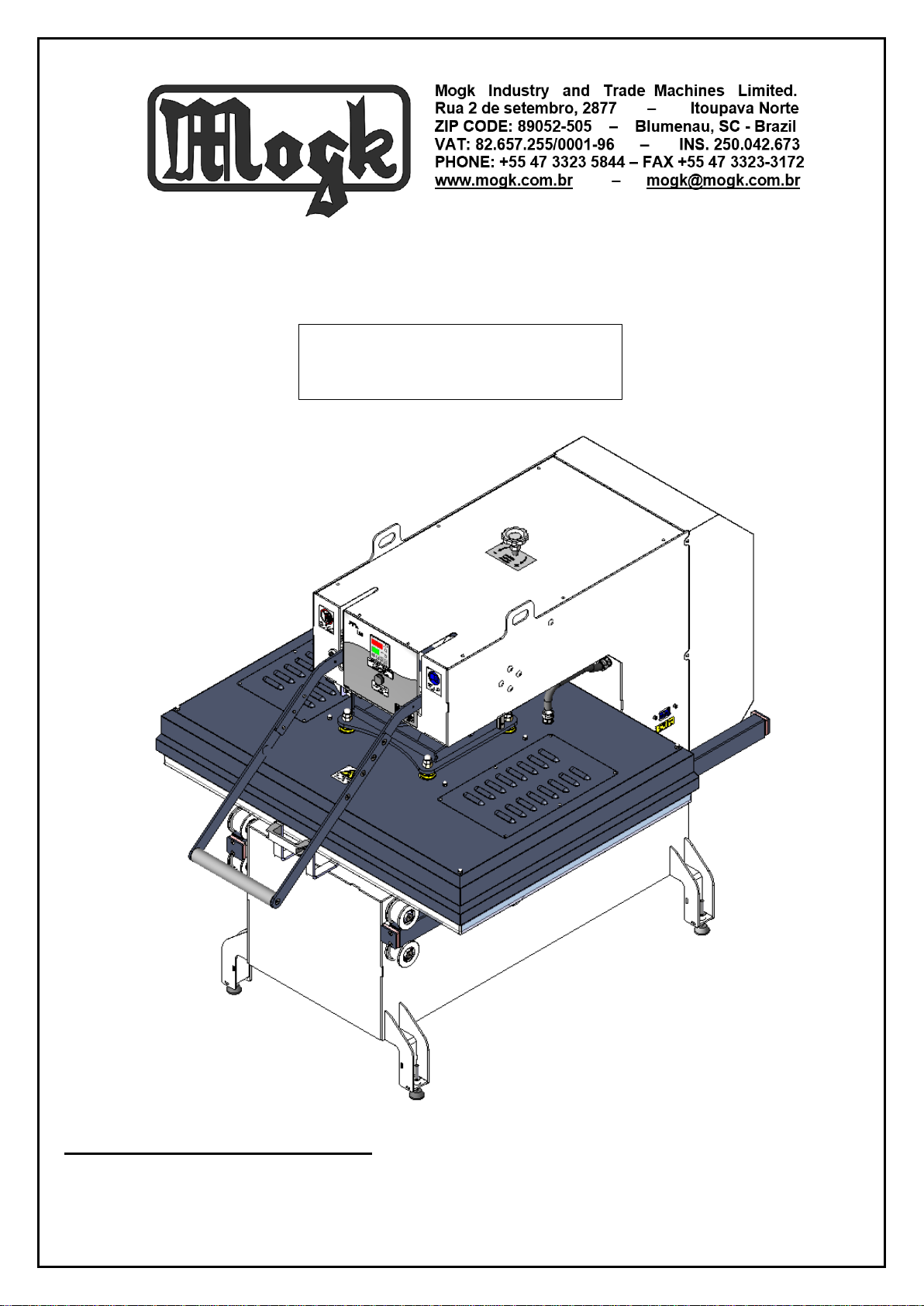

2.3 About the Equipment........................................................................................................4

2.4 About Manual ....................................................................................................................5

3 GENERAL INFORMATIONS.....................................................................................................5

3.1 Receipt and verification ...................................................................................................5

3.2 Identification......................................................................................................................5

4 INSTALLATION......................................................................................................................... 6

4.1 Operation of machine.......................................................................................................6

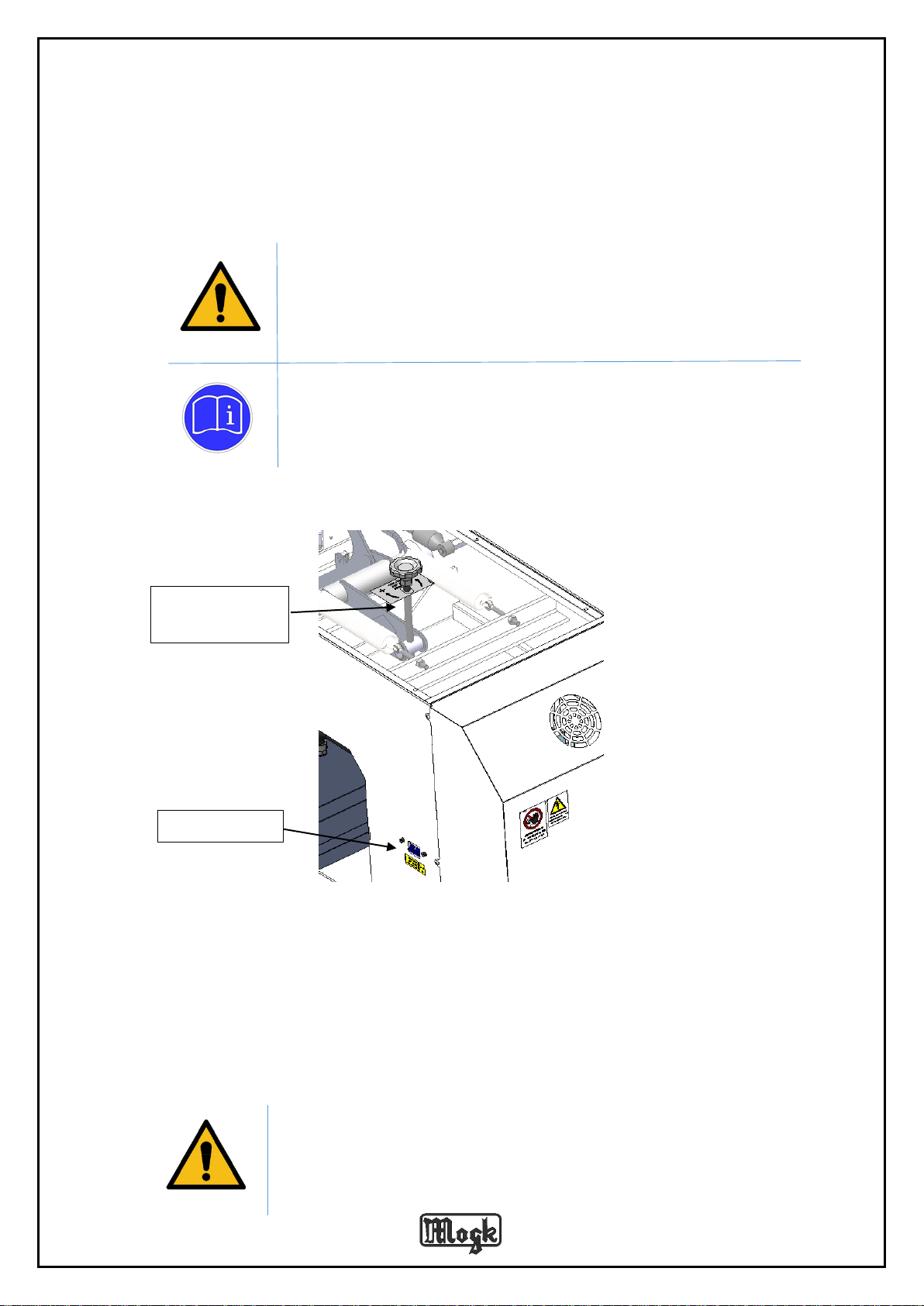

4.2 Pressure Control............................................................................................................... 7

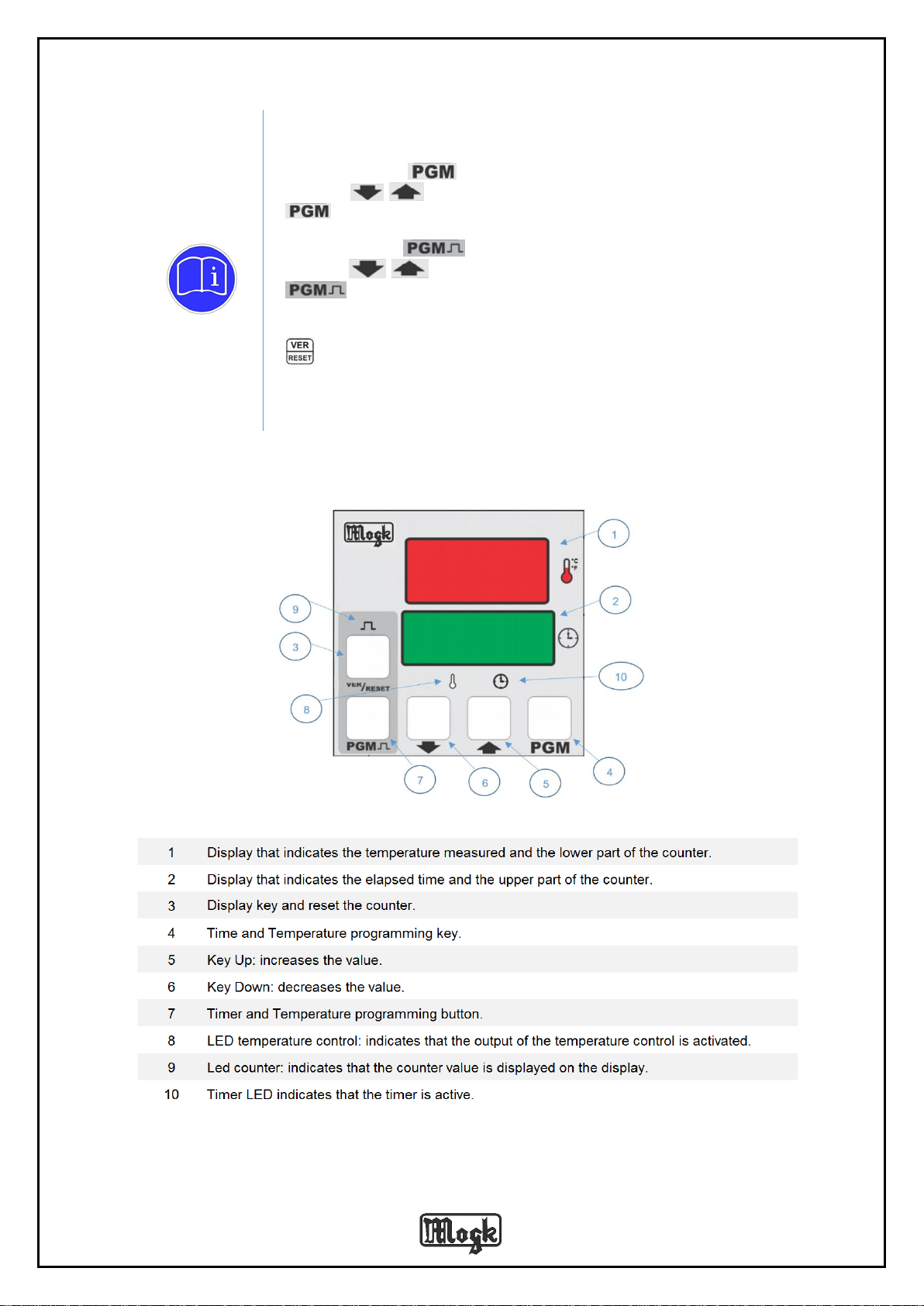

4.3 Control Panel - Programming Parameters .....................................................................7

5 MAINTENANCE.........................................................................................................................9

5.1 Cleaning.............................................................................................................................9

5.2 Spare Parts ........................................................................................................................9

5.3 Technical Assistance .....................................................................................................10

6 TECHNICAL DATA AND INFORMATION ..............................................................................11

7 ELECTRICAL SCHEMATIC....................................................................................................12

8 ASSEMBLY DRAWINGS AND SPARE PARTS.....................................................................13

8.1 List of Materials...............................................................................................................13

8.2 General Assembly...........................................................................................................14

8.3 Top platen assembly ......................................................................................................19

8.4 Lower platen assembly ..................................................................................................20

9 WARRANTY CERTIFICATE....................................................................................................21

10 APPENDIX.............................................................................................................................22

10.1 Procedimento Iniciais –Remoção da Trava de Transporte .....................................22

10.2 Procedimentos para Ligar............................................................................................22

10.3 Digital controller ...........................................................................................................22