iv

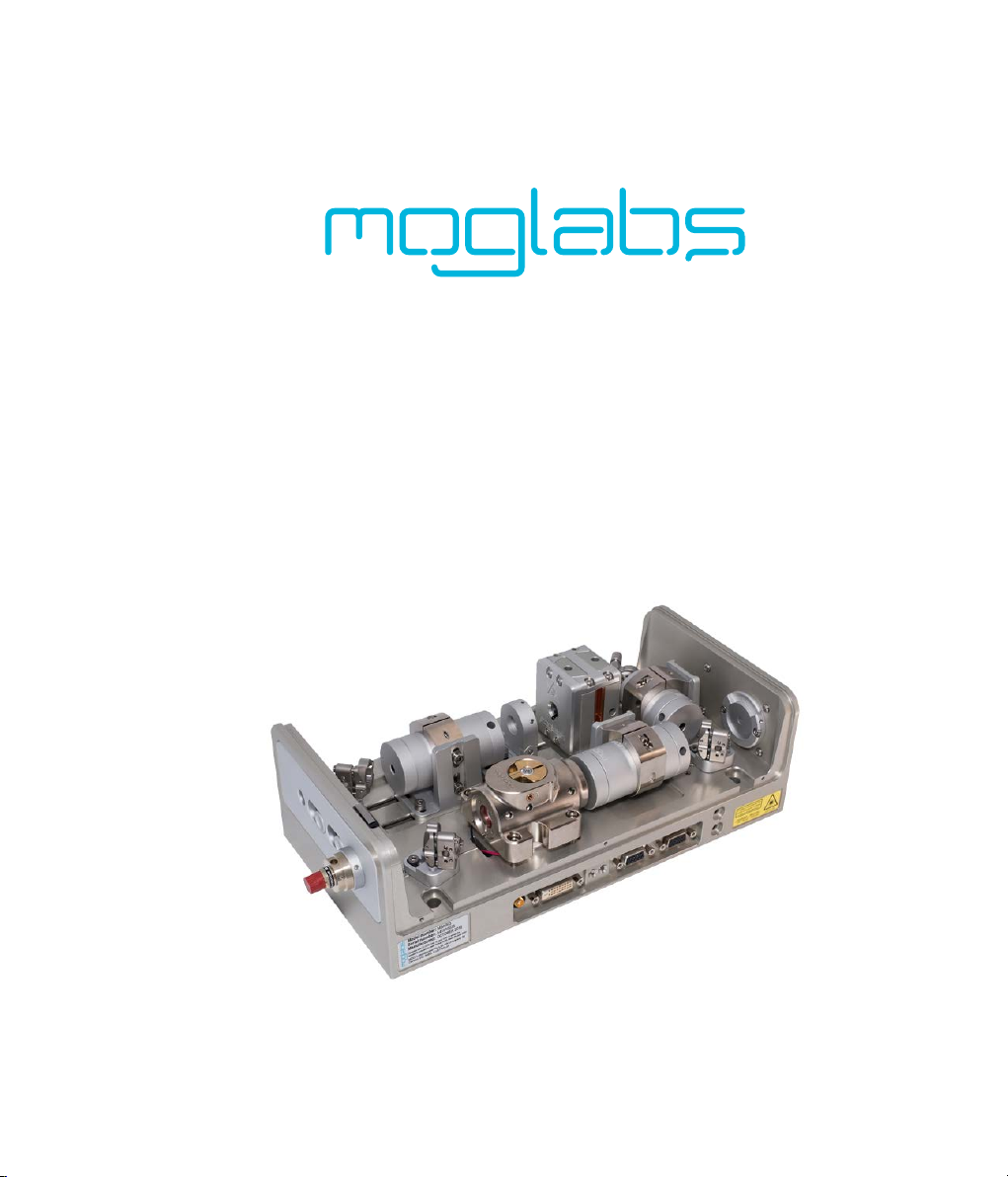

•Note the safety labels (examples shown in figure 1) and heed their

warnings.

•The MSA or MOA must be operated with a controller with keyswitch

interlock. The MSA must not be powered unless the keyswitch is

inserted and switched on. It should not be possible to remove the

keyswitch without turning off the power to the MSA or MOA.

•When the seed laser and amplifier are switched on, there should

be a delay of two seconds before the emission of laser radiation,

mandated by European laser safety regulations (IEC 60825-1).

WARNING Do not operate the amplifier without sufficient seed laser input. It is

important that an injection seed laser beam is coupled into the ta-

pered amplifier (TA) diode so that most of the electrical input energy

is converted to optical output rather than lost as heat, which would

damage the TA diode.

NOTE The MOGLabs MSA and MOA are designed for use in scientific re-

search laboratories. They should not be used for consumer or medical

applications.

Protection Features

The MOGLabs MSA and MOA include a number of features to protect you

and the device. They should be used with a power supply that provides

additional safety features such as key lock operation, current limit, tem-

perature limit, cable continuity and short-circuit detection, soft-start and

turn-on delay.

Protection relay When the power is off, or the temperature controller is

off, the amplifier diode is shorted via a normally-closed relay.

LEDsSeparate LED indicators illuminate when the seed laser and amplifier

diode current supplies are enabled.