INSTALLATION GUIDELINES

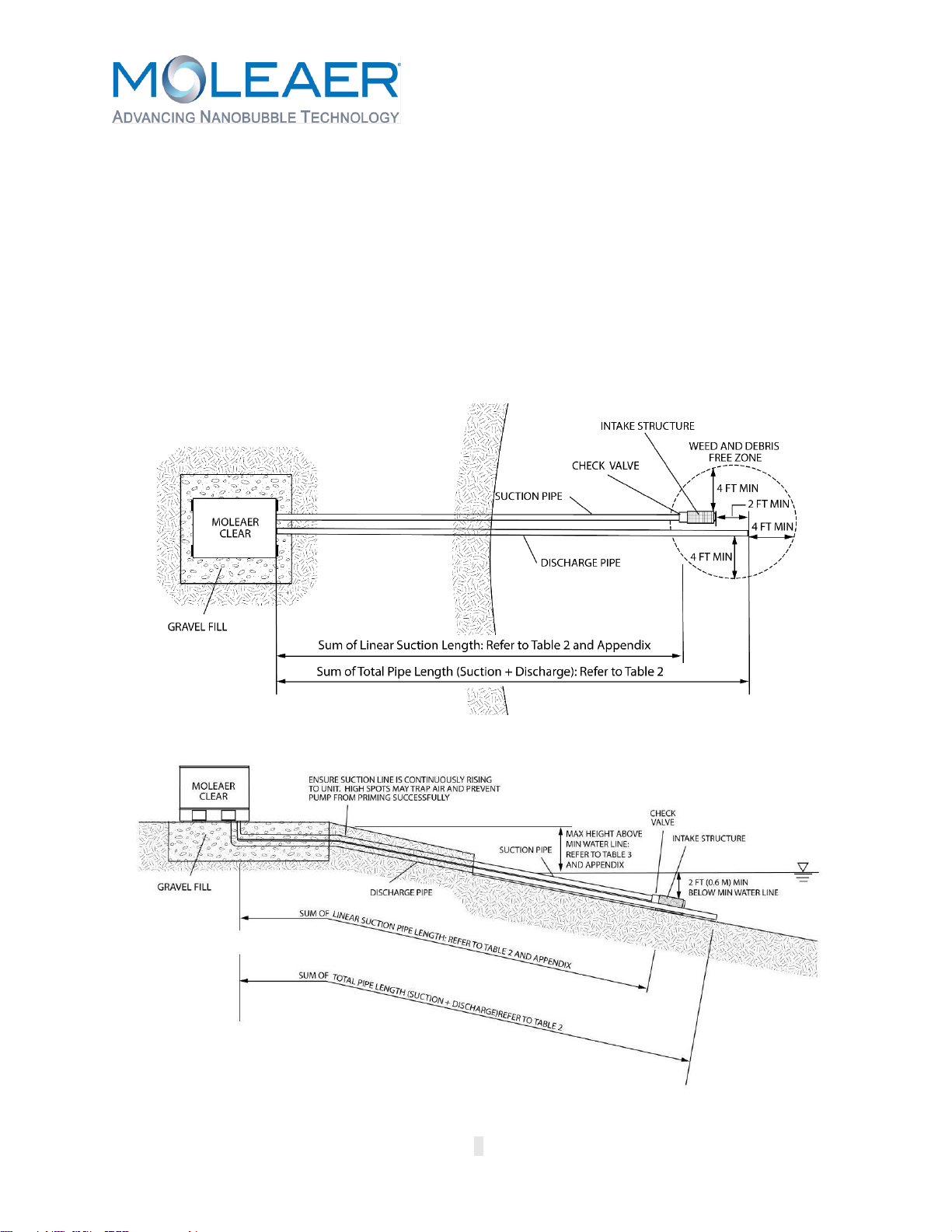

The unique site conditions for each waterbody should be carefully considered when identifying

the Clear installation location. Refer to the Location Requirements section of this guide for

addition details.

The guidelines herein are recommended for calm waterbodies with intake structure depths less

than 10 ft (3 m). For deeper water intakes or high current waterbodies, contact a Moleaer

sales representative or call (424) 558-3567 prior to purchasing a Clear.

Upon delivery, unscrew the shipping screws to remove the Clear from the shipping crate. Inspect

the Clear for any damage or loose parts that may have occurred during transport. Hand tighten

any loose parts.

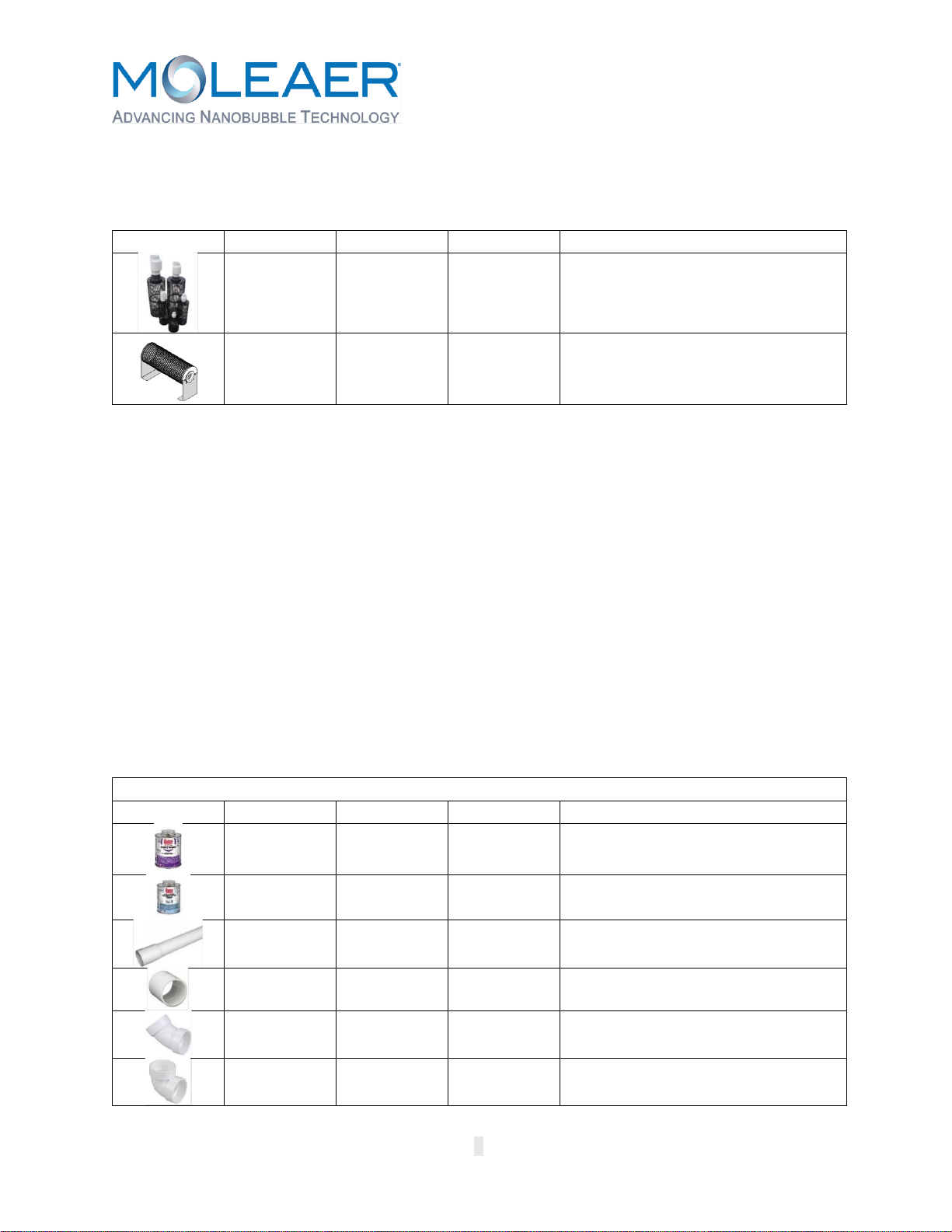

Installation Parts and Materials

The parts and materials required to install the Clear include:

•A shovel

•25 cubic feet (0.7 cubic meters) of all-purpose gravel

•PVC saw

•PVC pipe primer and PVC pipe cement

•Clear Installation Kit or installation kit parts listed in Table 5

Pipe Assembly

Completely bury or submerge all PVC pipe and fittings to avoid ultraviolet (UV)

degradation. All PVC pipe connections must be solvent welded using PVC cement. Use

only Schedule 40 polyvinyl chloride (PVC) pipe and fittings. Use only PVC cement formulated for

wet condition and fast installation to connect PVC pipe to PVC fittings. Do not use black,

acrylonitrile butadiene styrene (ABS) piping or mix ABS pipe or fittings with PVC pipe or fittings.

All PVC pipe connections must be airtight and leakproof. Failure to provide airtight suction

pipe connections may negatively impact nanobubble generator performance. Large

bubbles visible at the pump strainer basket is an indication of suction pipe leaks. Difficulty with

pump priming may also be an indication of suction pipe leaks. Check and correct for all suction

and discharge pipe leaks prior to burying or submerging pipe.

Proper technique must be used when gluing PVC pipe and fittings to ensure an airtight, leakproof

connection. For proper technique, refer to the Appendix. Allow for proper cure time to lapse

before wet testing suction and discharge pipes. Refer to Appendix, Item 8 for cure times.

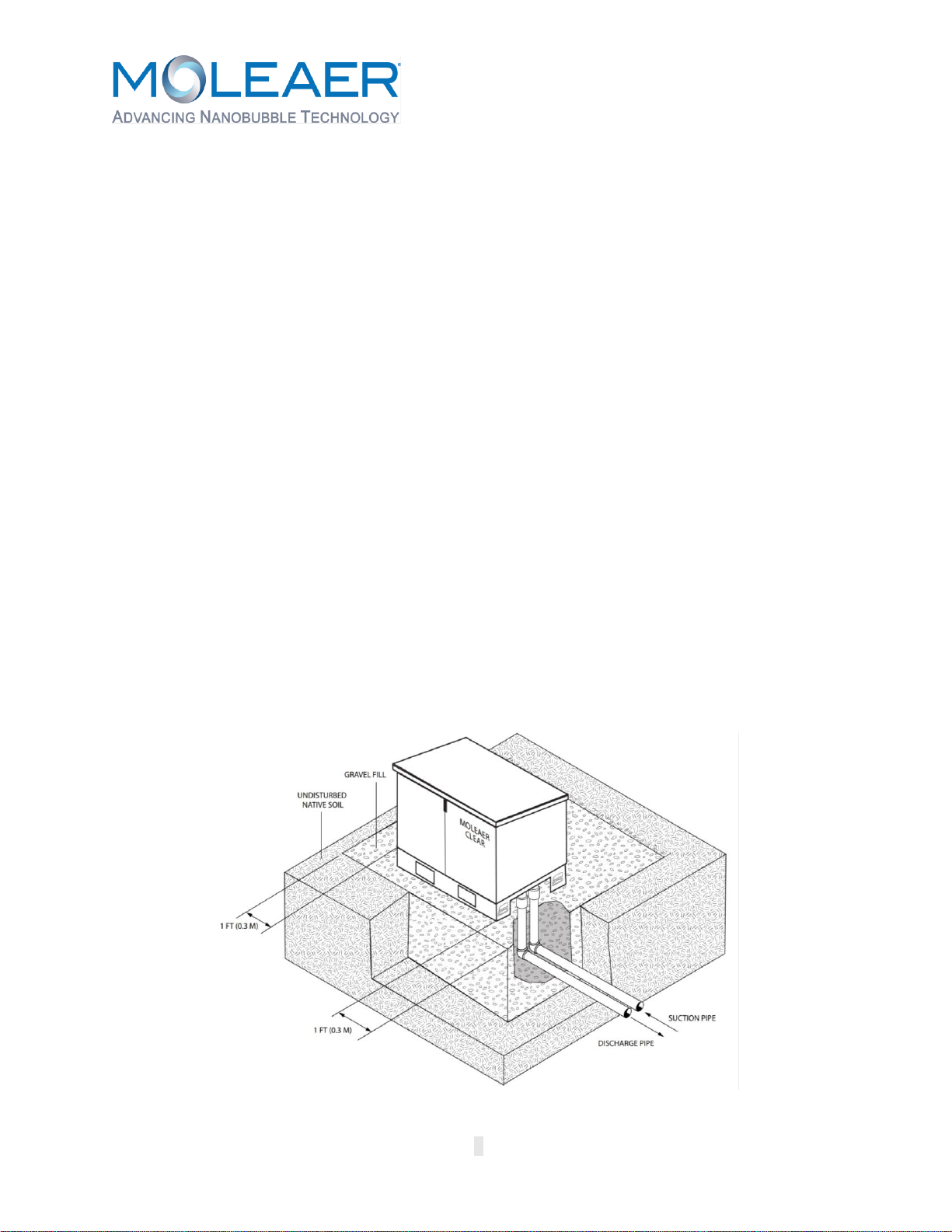

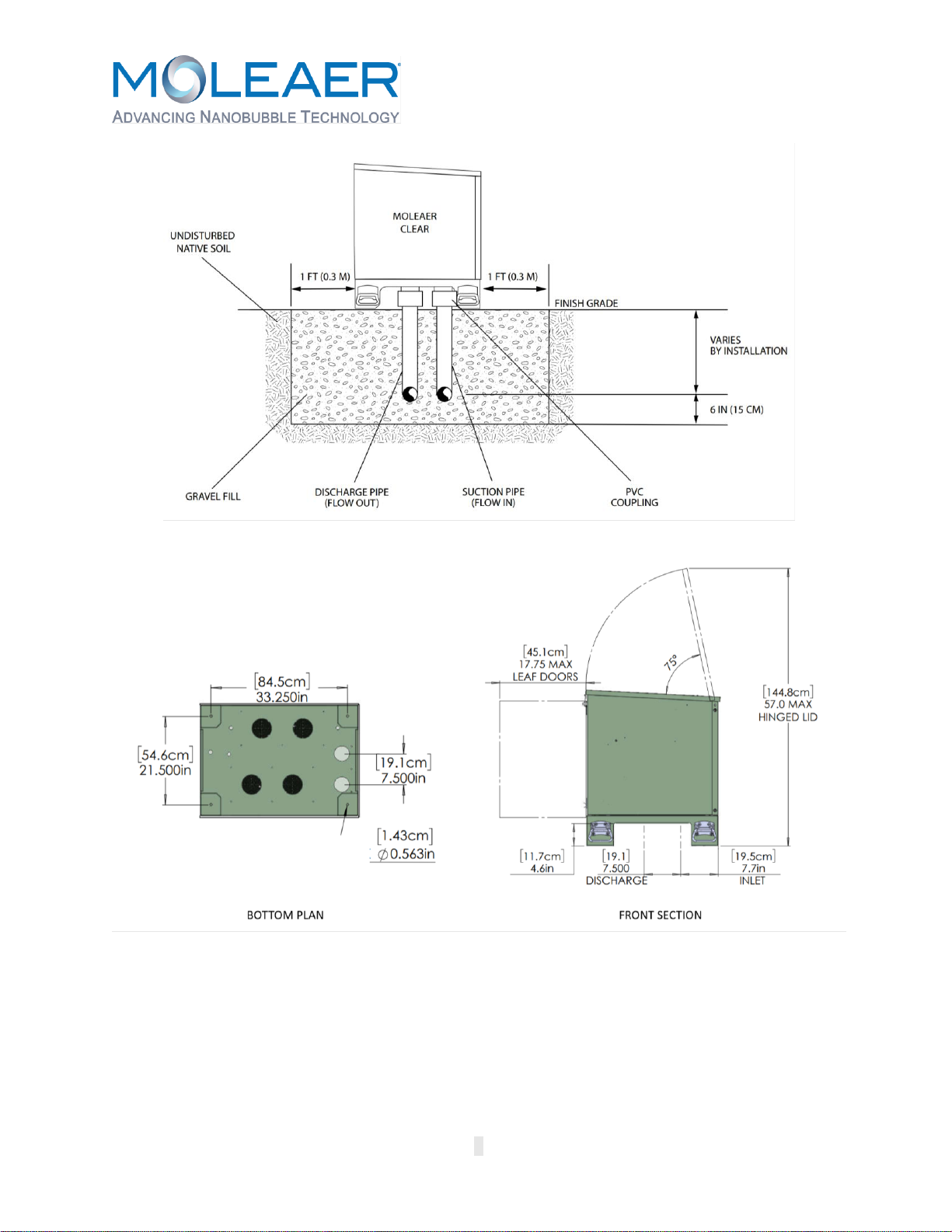

Clear Installation

The installation diagrams for the Clear are shown in Figures 3 and 4. Using a shovel, dig a hole

approximately 5 ft (1.5 m) Long (L) x 5 ft (1.5 m) Wide (W) x 1 ft (0.3 m) Deep (D). The Clear will

be installed with the pressure gauges facing away from the waterbody. Near the edge of the hole