molex 200218-2600 User guide

Other molex Crimping Tools manuals

molex

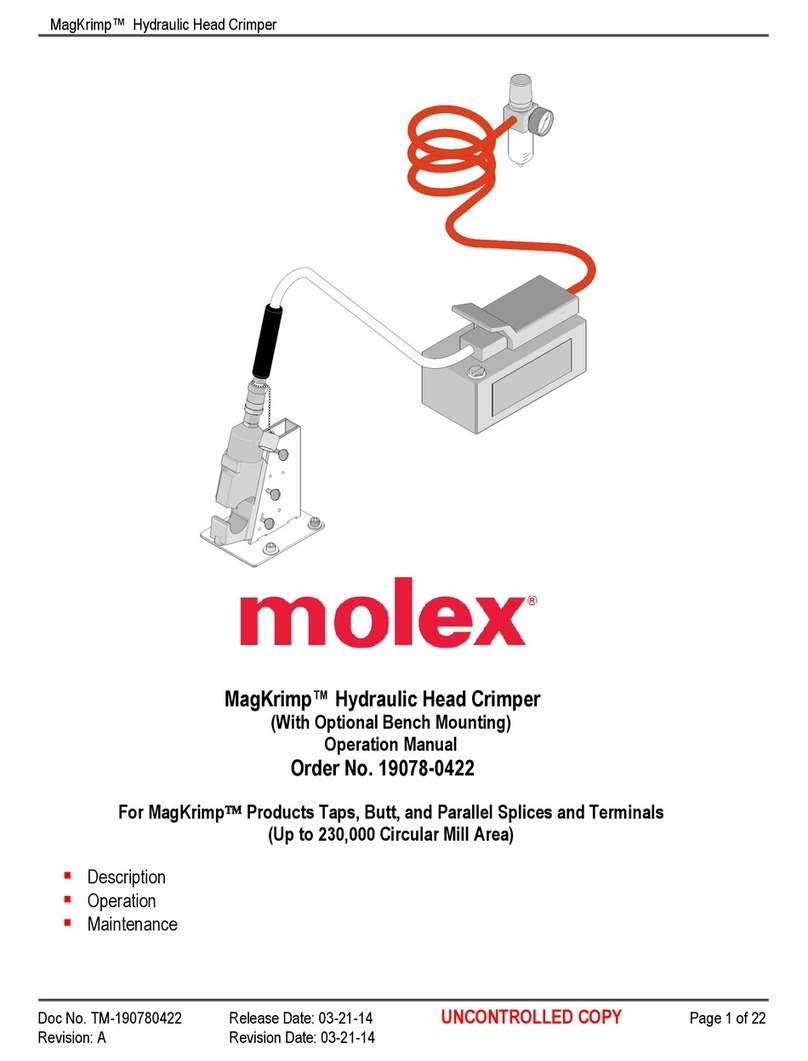

molex MagKrimp 19078-0422 User manual

molex

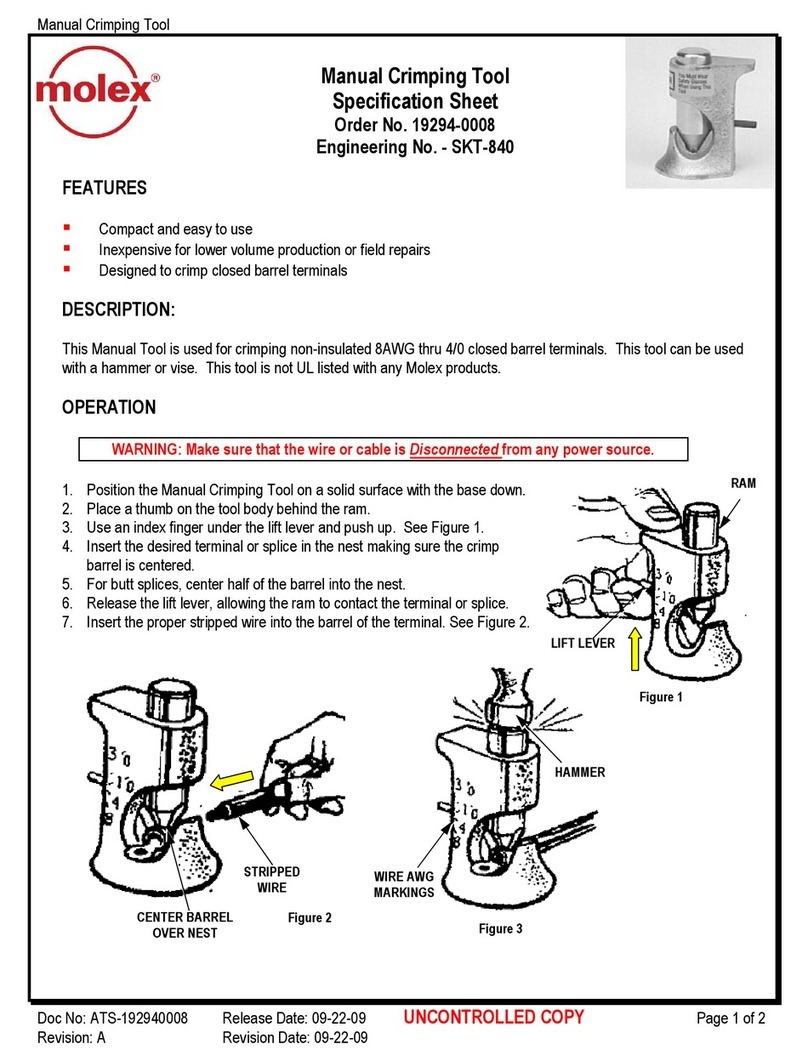

molex 19294-0008 User manual

molex

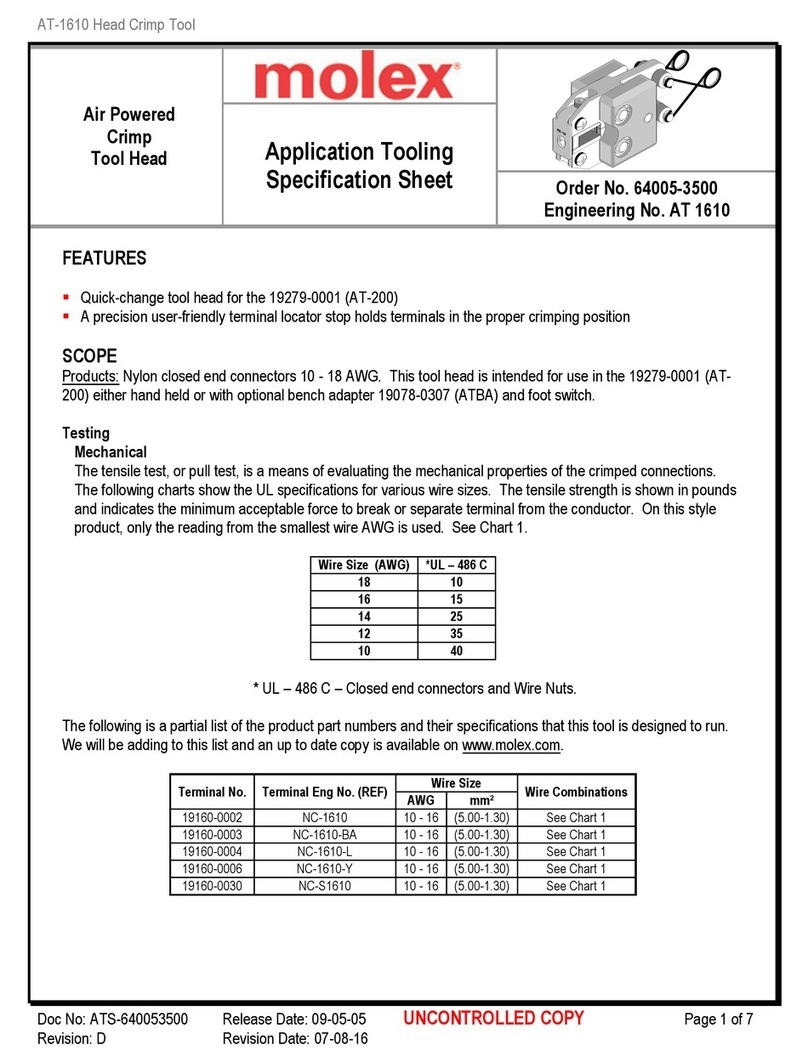

molex AT 1610 User manual

molex

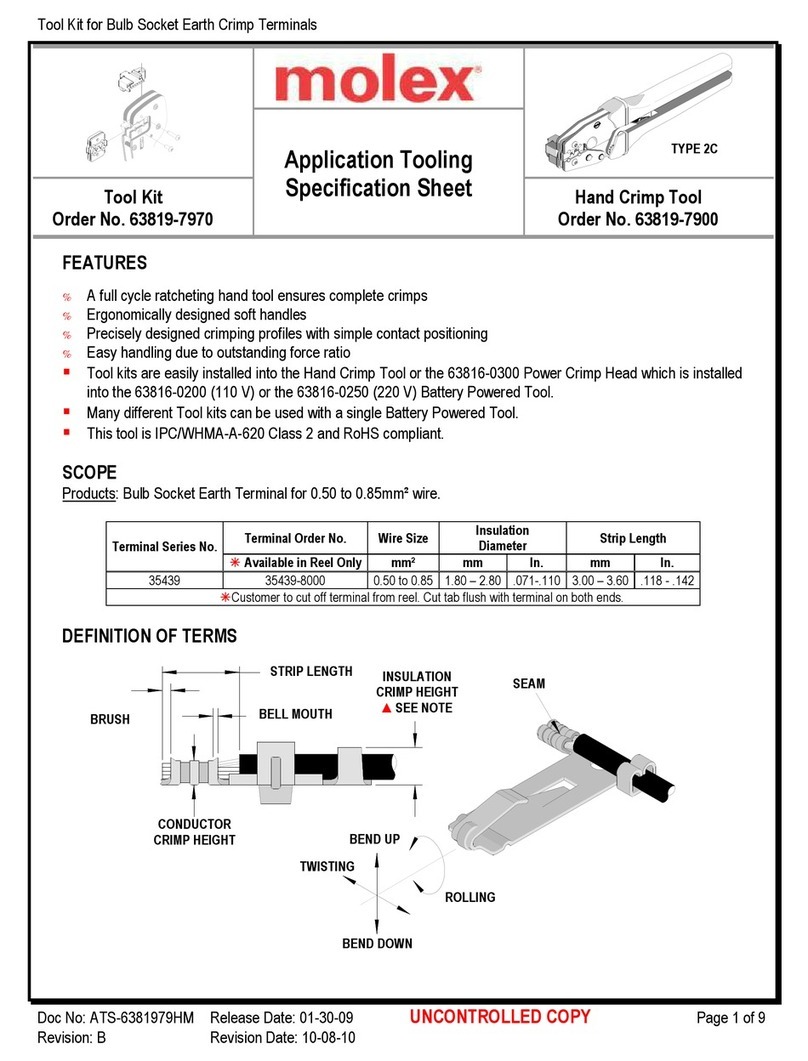

molex 207129 Series User manual

molex

molex 63825-9400 User guide

molex

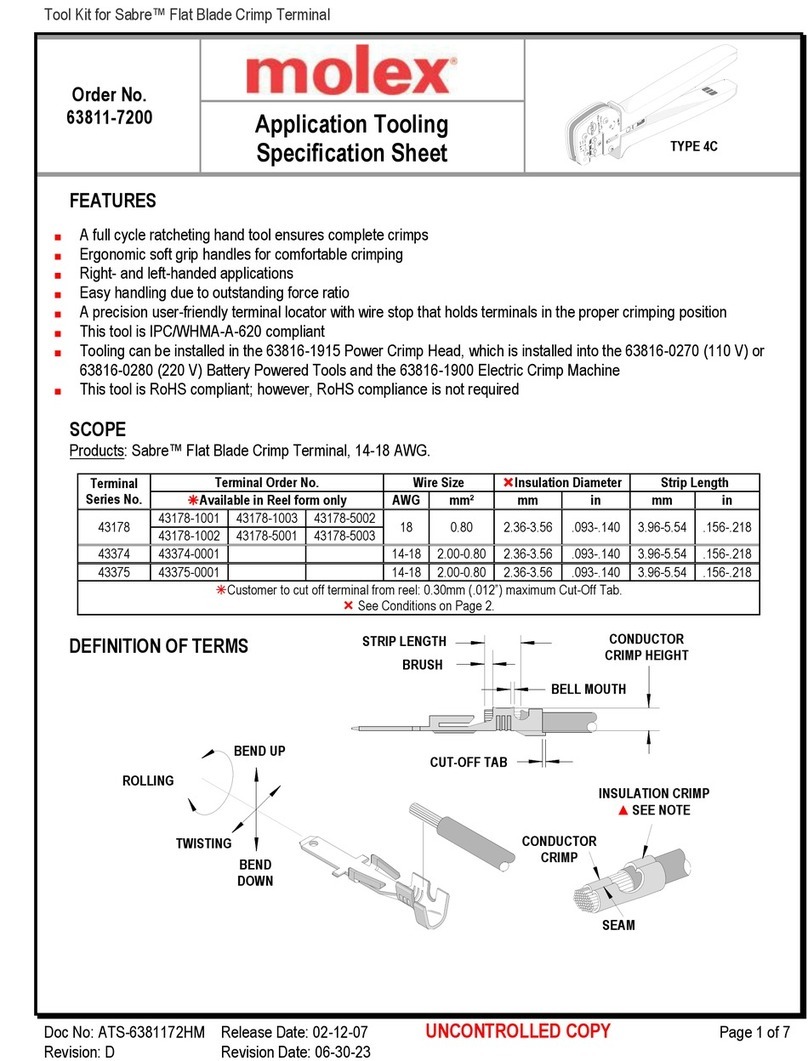

molex 63811-7200 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

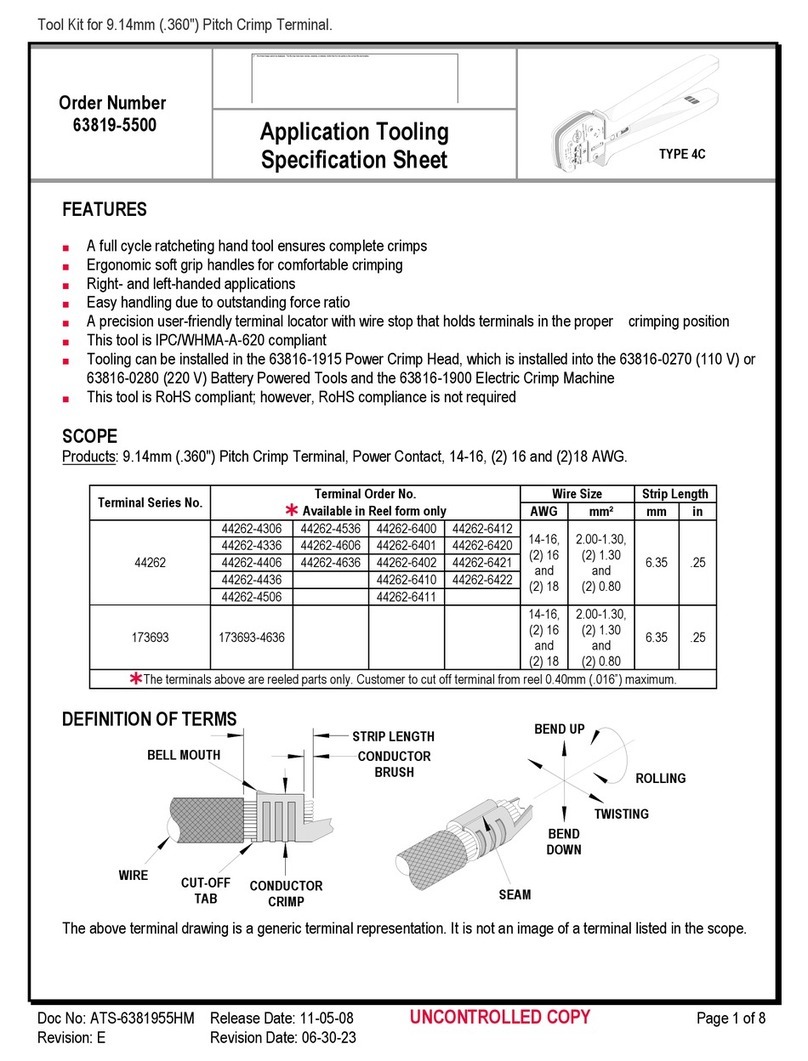

molex 44262-4306 User manual

molex

molex 63811-5500 User manual

molex

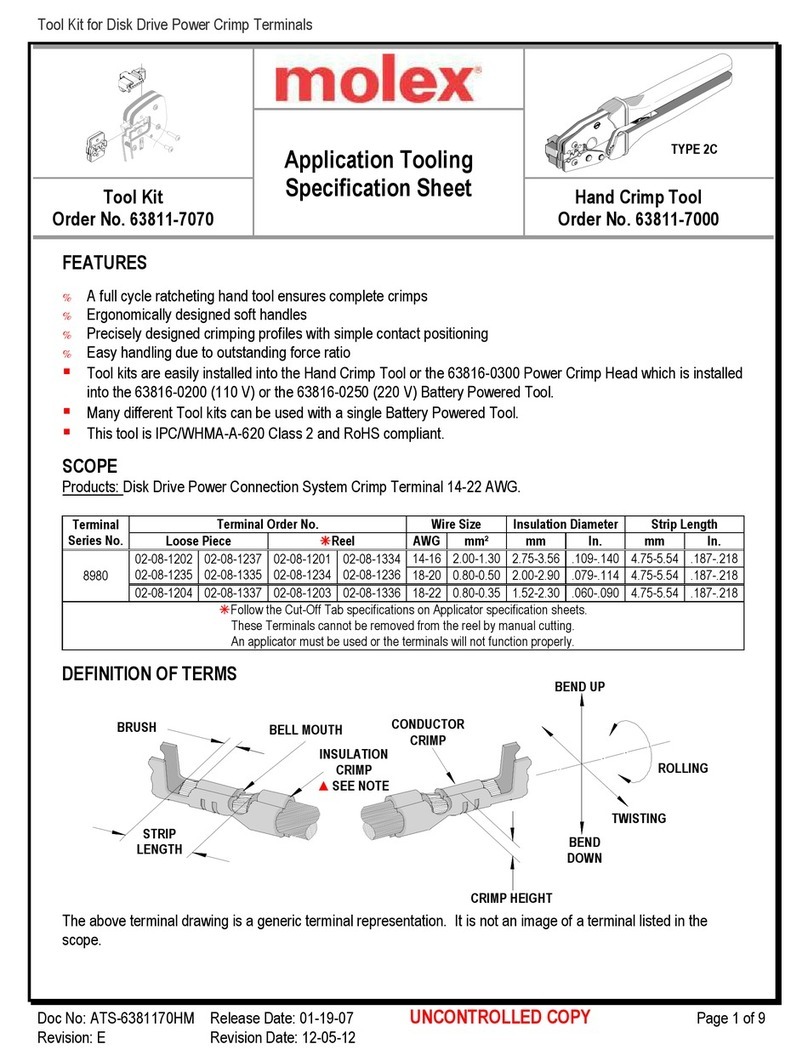

molex 63811-7070 User manual

molex

molex 207129 Series User manual

molex

molex 63827-8200 User manual

molex

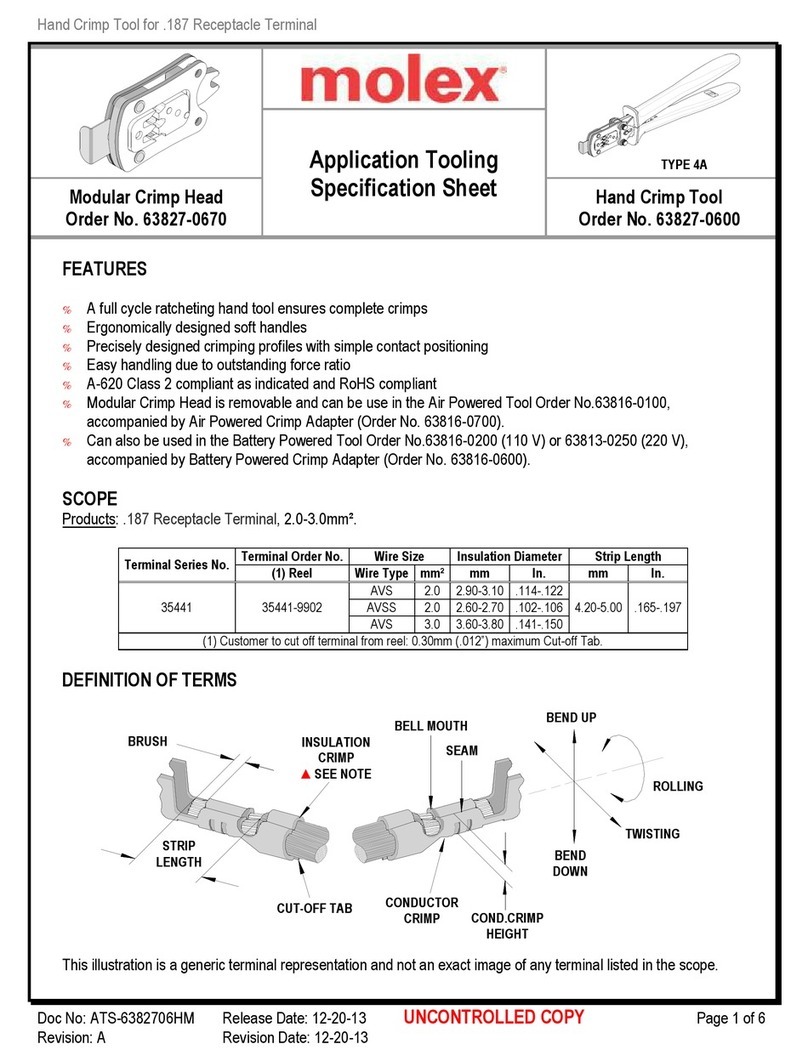

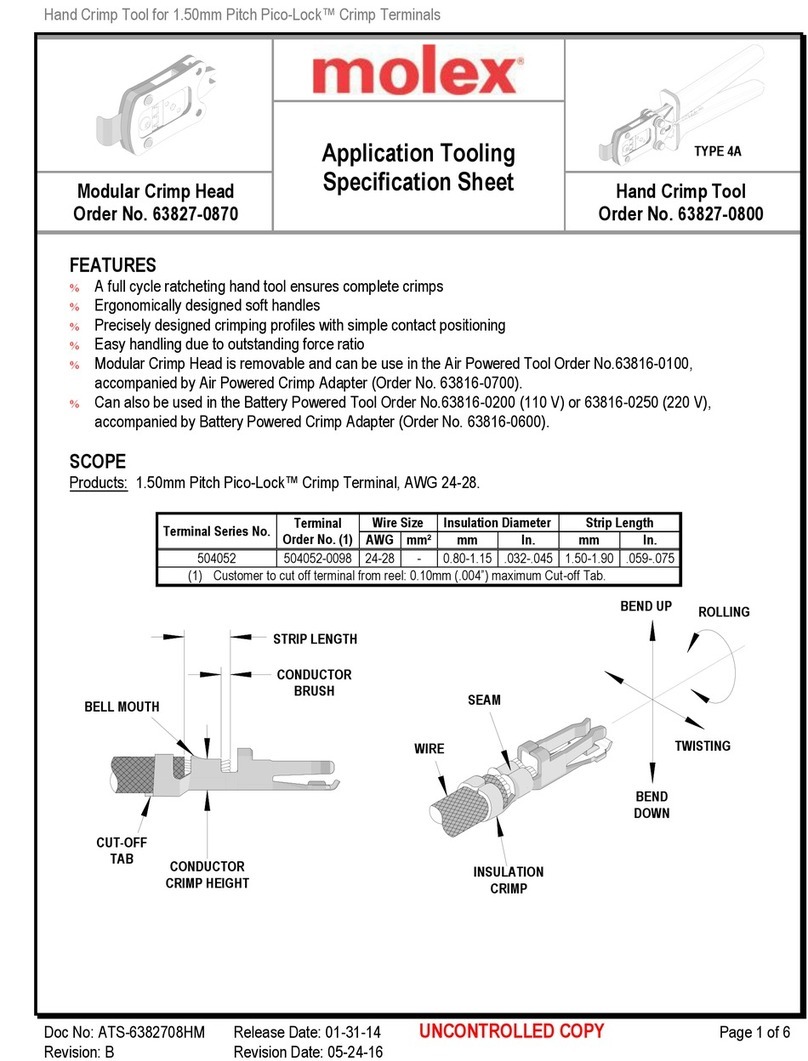

molex 63827-0600 User manual

molex

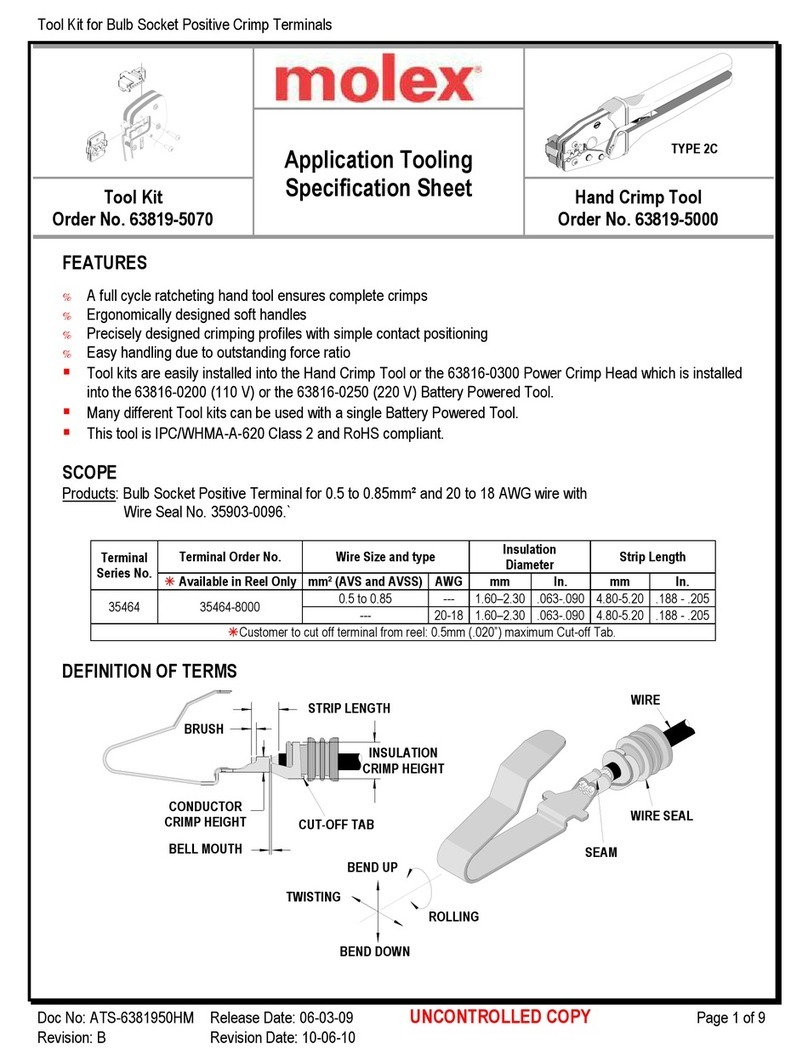

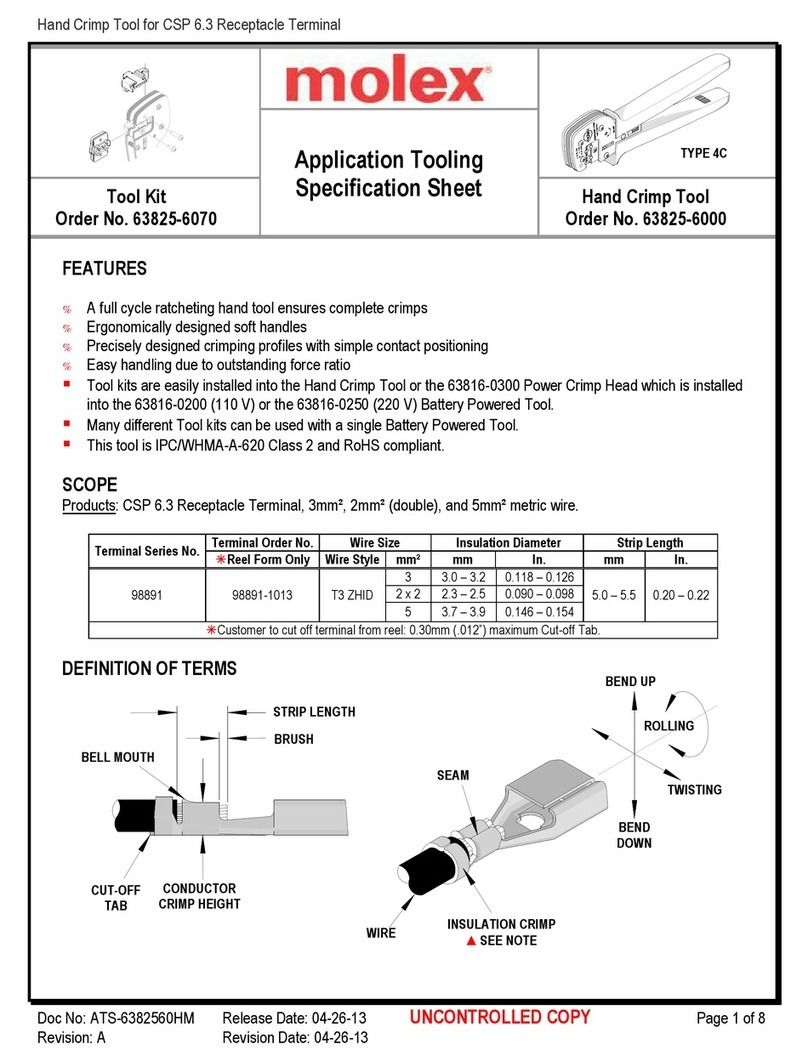

molex 63825-6070 User manual

molex

molex 63811-6170 User manual

molex

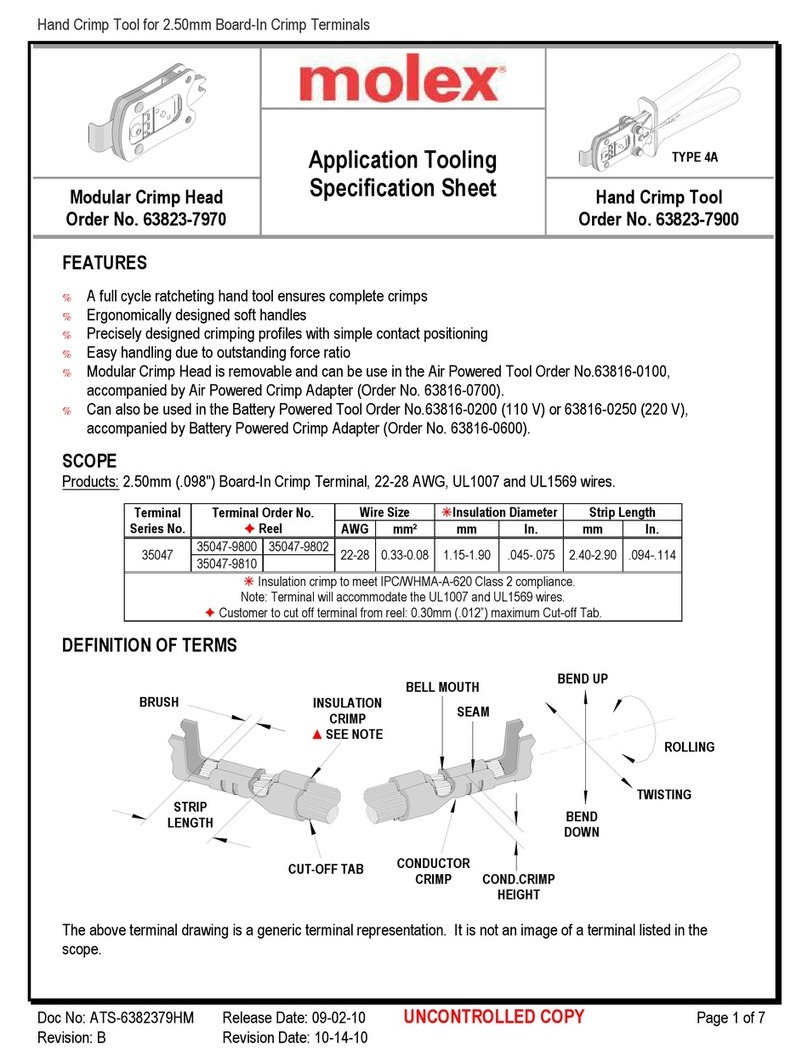

molex 63823-7970 User manual

molex

molex 207128 Series User manual

molex

molex CR5905 User manual

molex

molex 64001-5900 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet