CR5905 Hand Crimp Tool

Doc No. 11-01-0195 Release Date: 04-13-93 UNCONTROLLED COPY Page 3 of 4

Revision: C Revision Date: 07-28-04

CAUTION: Molex crimp specifications are valid only when used with Molex terminals, applicators and tooling.

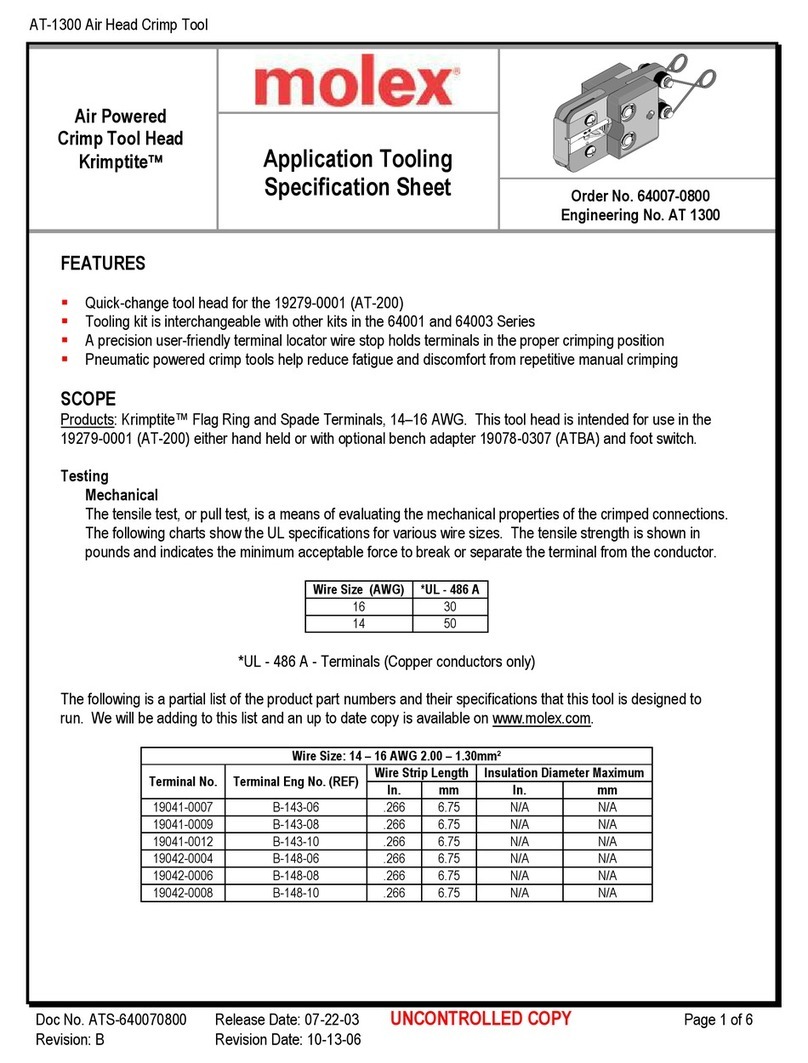

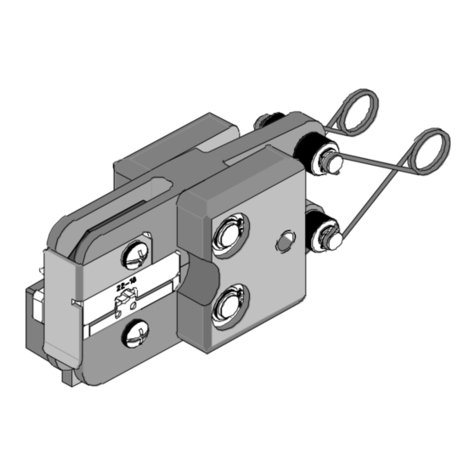

How To Adjust Tool Crimp Force (See Figure 4)

It may be necessary over the life of the tool to adjust tool-crimping force. Listed below are the steps required to adjust the crimping force

of the hand tool to obtain proper crimp conditions:

1. Remove the screw and washer. Located over the adjustment ring.

2. Lift the adjusting ring slightly, off of the locating pin.

3. Turn the adjusting ring in the desired direction (L= less force, T= more force) to increase or decrease crimp pressure.

4. Press the adjusting wheel flat against the tool and engage the locking pin.

5. Replace the washer and screw.

6. Check the crimp specifications after tool crimp force is adjusted.

Warranty

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components are long

life tested. All tools are warranted to be free of manufacturing defects for a period of 30 days. Should such a defect occur, we

would exchange the tool free of charge. This will not be applicable to altered, misused, or damaged tools. This tool is designed for

hand use only. Any clamping, fixturing, or use of handle extensions voids this warranty.

Hand held crimping tools are intended for low volume, prototyping or repair requirements only.

Notes:

1. This tool should only be used for the terminals and wire gauges specified on this sheet.

2. This tool is not adjustable for crimp height, however crimp force is adjustable (See instructions above). Variations in tools,

terminals, wire stranding and insulation types may affect crimp height.

3. This tool is intended for standard conductor sizes. It may not give a good insulation crimp support for all insulation sizes.

4. Molex does not repair hand tools (see warranty above) The replacement parts listed are the only parts available for repair. If the

handles or crimp tooling is damaged or worn, a new tool must be purchased.

5. Pull force should be used as the final criteria for an acceptable crimp. Pull force is measured with no influence from the

insulation crimp. The insulation should be stripped long (1/2 in.) so the insulation grips on the terminal do not grip the wire

insulation or the conductor. Refer to Molex Quality Crimping Handbook 63800-0029 for additional information on crimping

and crimp testing.

6. Molex does not certify crimp hand tools.

Caution: Repetitive use of this tool should be avoided.