molex 63811-7070 User manual

Other molex Crimping Tools manuals

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User guide

molex

molex 63825-9670 User manual

molex

molex 63811-4400 User manual

molex

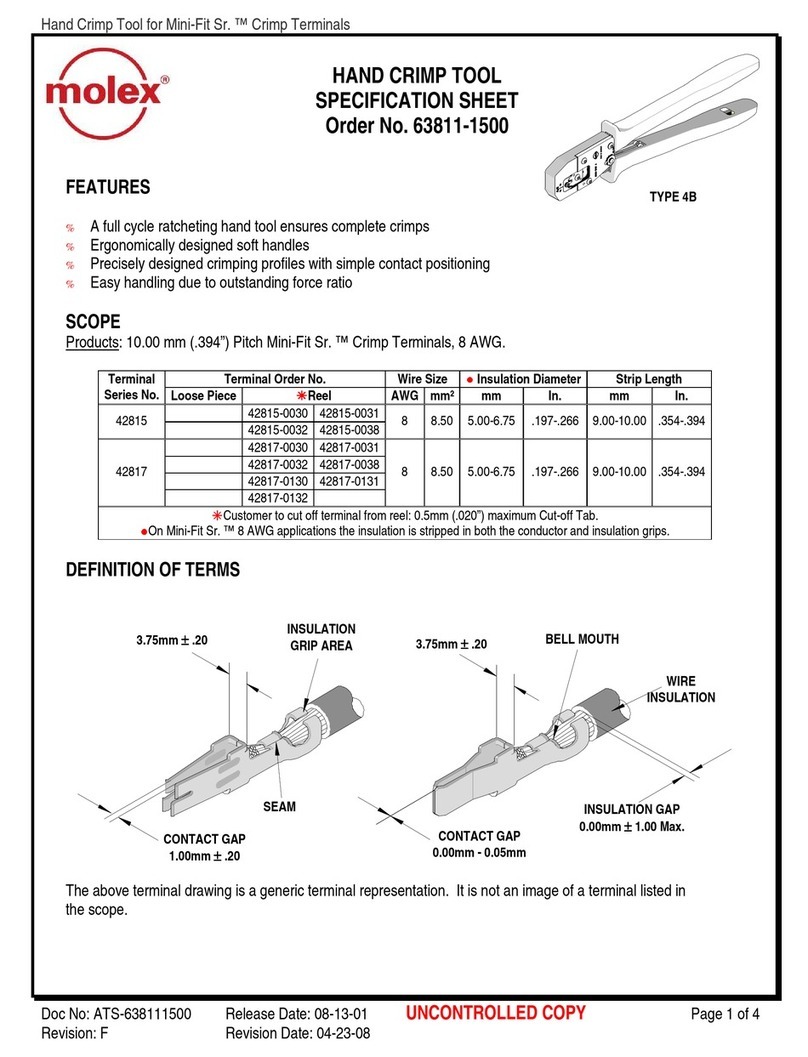

molex 63811-1500 User manual

molex

molex Perma-Seal 64005-4500 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 64005-6400 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

molex 63816-0800 User manual

molex

molex 207129 Series User manual

molex

molex 207129 Series User manual

molex

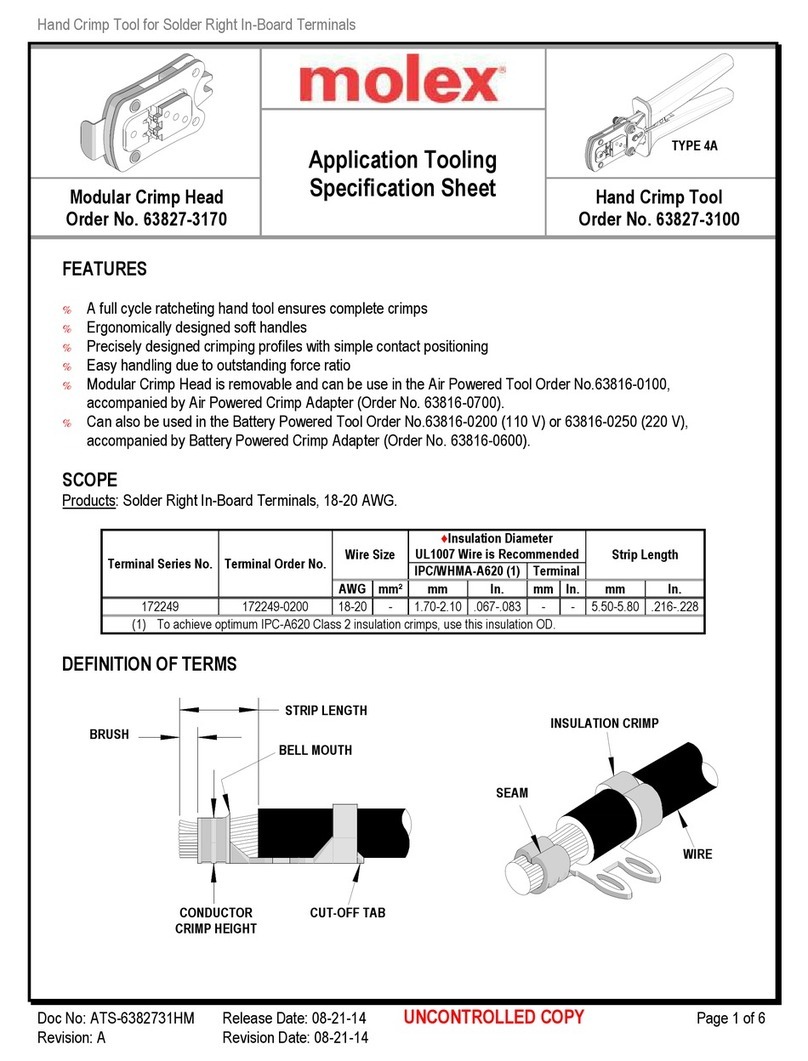

molex 63827-3170 User manual

molex

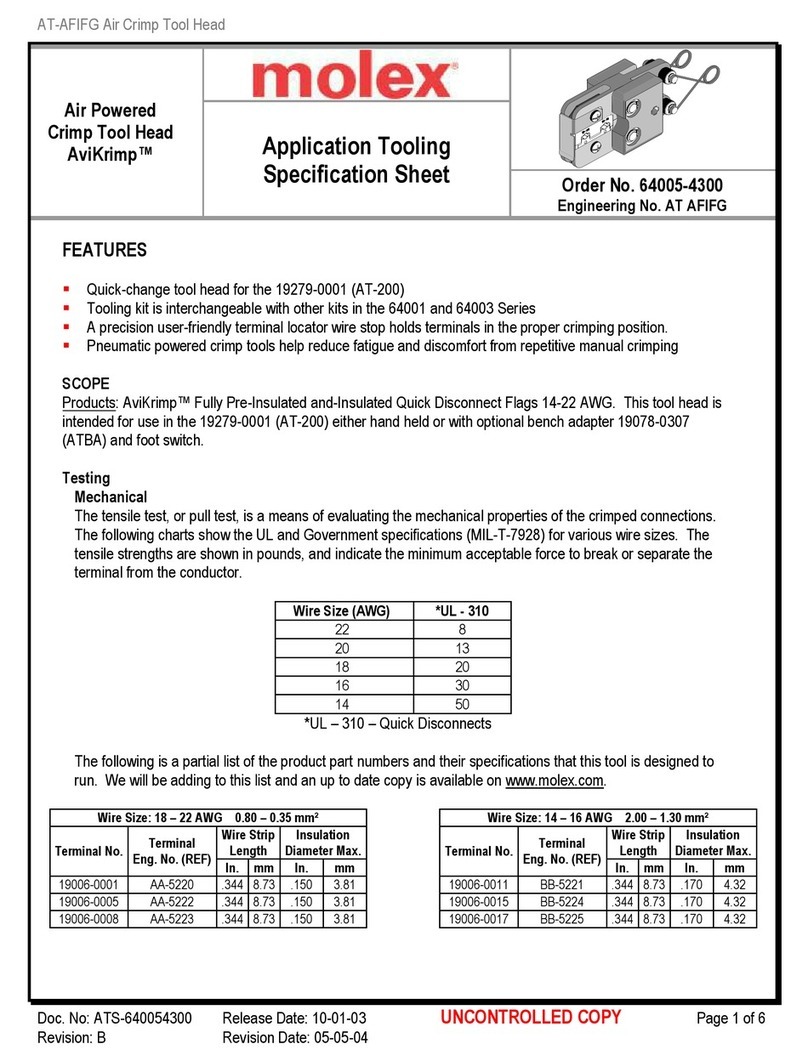

molex AT AFIFG User manual

molex

molex CR1031E User manual

molex

molex MOLEX User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

TE Connectivity

TE Connectivity 539 726-2 instruction sheet