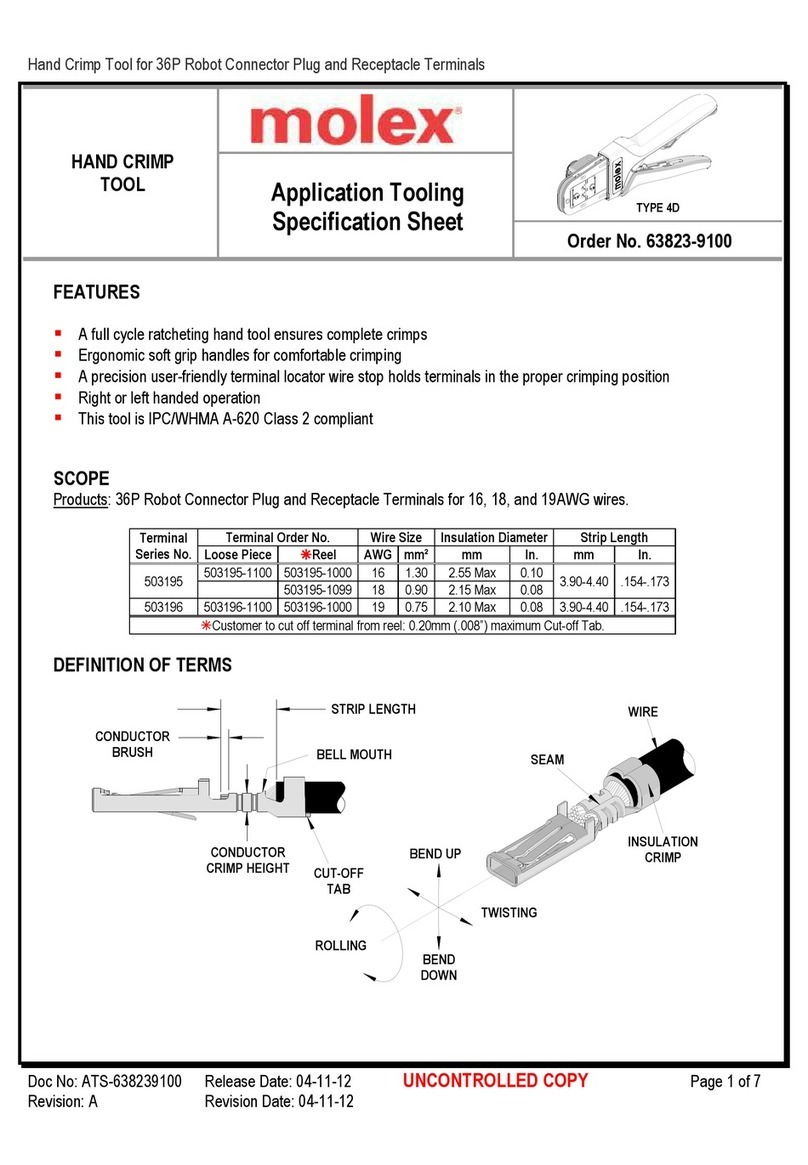

Hand Crimp Tool For 2.00mm (.079”) Pitch CLIK-Mat ™ Wir -to-Board Crimp T rminals

Doc No: ATS-638192800 R l as Dat : 07-08-08 UNCONTROLLED COPY Pag 6 of 7

R vision: B R vision Dat : 01-27-12

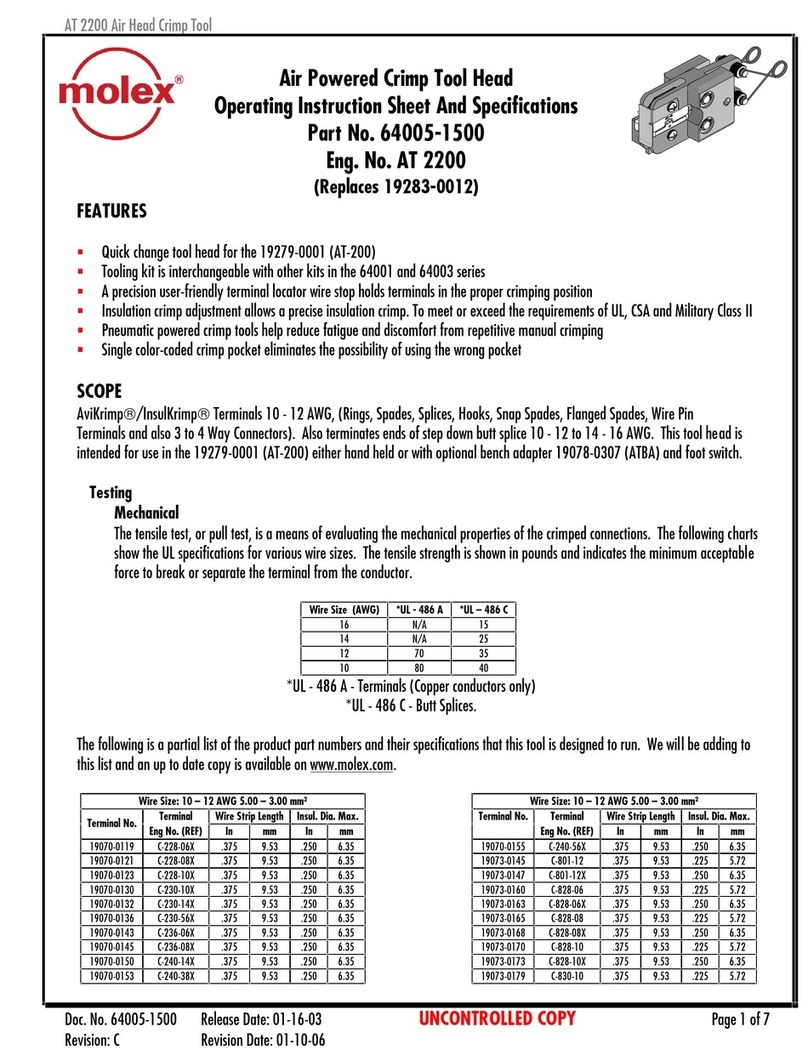

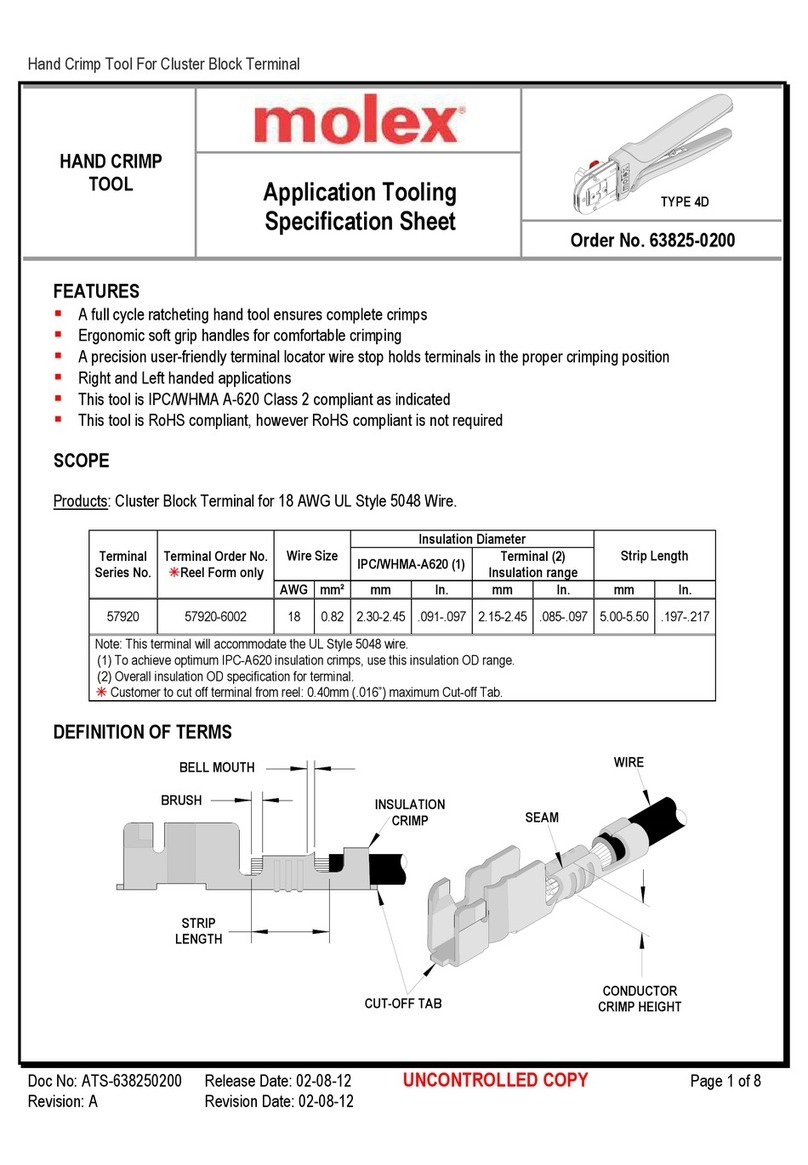

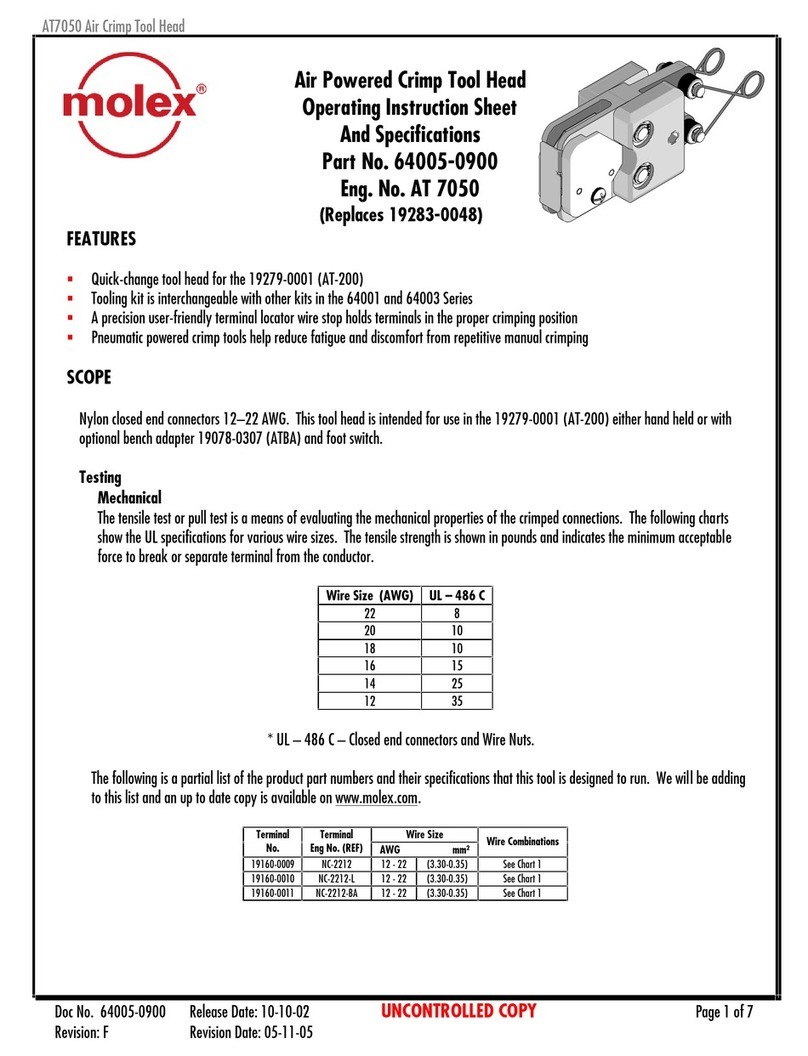

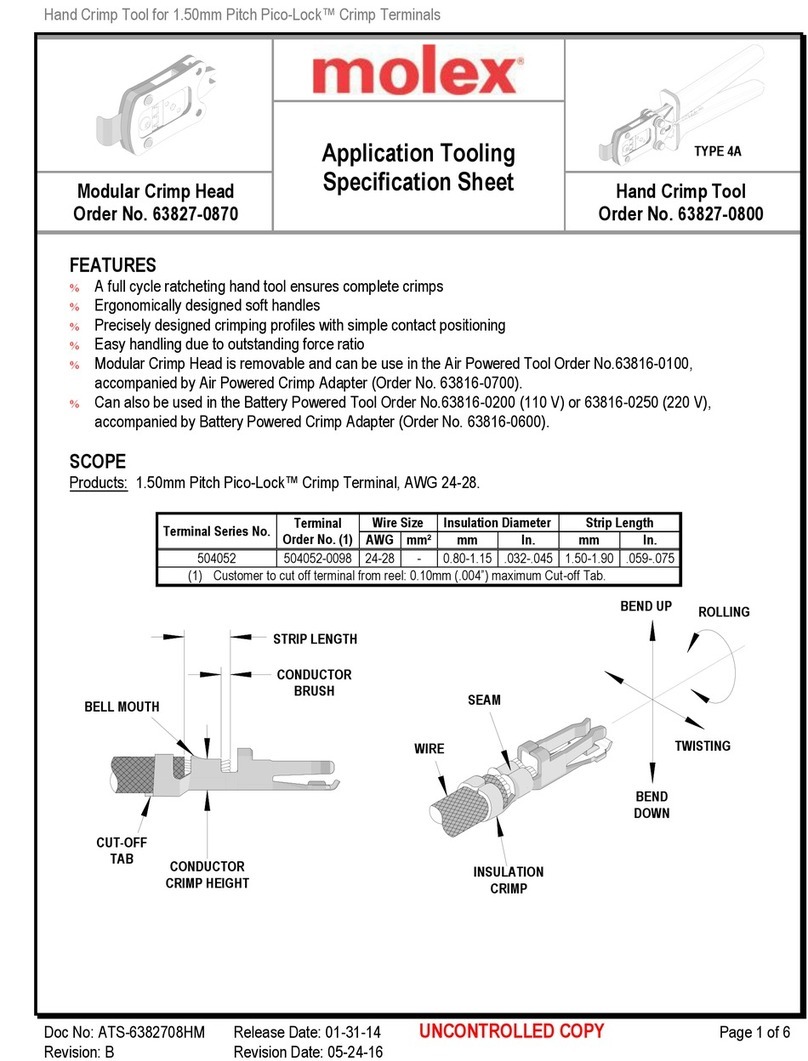

Figure 12

SQUEEZE

THE LINK IN

THE HANDLE

HOLD THE HAND

TOOL IN POSITION

SETTING

WHEEL

RATCHET

RELEASE LEVER

How to Adjust Tool Preload (See

Figure 12)

This hand tool is factory pr s t to 25-45

LBS. pr load. It may b n c ssary ov r

th lif of th tool to adjust tool handl

pr load forc . List d b low ar th st ps

r quir d to adjust th crimping forc of th

hand tool to obtain prop r crimp

conditions:

1. Hold th hand tool in th palm of your

hand as shown in Figur 12. Using

th ind x fing r squ z th link

towards th top of th hand tool fram .

This will r l as th pr load adjustm nt wh l.

2. Rotat th s tting wh l count r-clockwis (CCW) to incr as handl forc . Th numb rs will display high r.

To d cr as handl forc rotat th s tting wh l clockwis (CW).

3. R l as th link to lock th s tting wh l in plac .

4. Ch ck th crimp sp cifications or conduct a pull t st aft r tool handl pr load forc is adjust d.

Warranty

This tool is for l ctrical t rminal crimping purpos s only. This tool is mad of th b st quality mat rials. All vital

compon nts ar long lif t st d. All tools ar warrant d to b fr of manufacturing d f cts for a p riod of 30

days. Should such a d f ct occur, w will r pair or xchang th tool fr of charg . This r pair or xchang will

not b applicabl to alt r d, misus d, or damag d tools. This tool is d sign d for hand us only. Any clamping,

fixturing, or us of handl xt nsions voids this warranty.

CAUTION: Mol x crimp sp cifications ar valid only wh n us d with Mol x t rminals and tooling.

CAUTIONS:

1. Manually pow r d hand tools ar int nd d for low volum or fi ld r pair. This tool is NOT int nd d for

production us . R p titiv us of this tool should b avoid d.

2. Insulat d rubb r handl s ar not prot ction against l ctrical shock.

3. W ar y prot ction at all tim s.

4. Us only th Mol x t rminals sp cifi d for crimping with this tool.

Certification

Mol x do s not c rtify or r -c rtify hand tools but rath r suppli s th following guid lin s for custom rs to r -c rtify

hand tools.

% This tool is qualifi d to pull forc only. S th Mol x w b sit for th Quality Crimp Handbook for mor

information on pull t sting.

% If th tool do s not m t minimum pull forc valu s, handl pr load should b incr as d and th pull t st

r run, (S How to Adjust Pr load).

% Wh n th hand tool is no long r capabl of achi ving minimum pull forc , it should b tak n out of s rvic and

r plac d.