Hand Crimp Tool for 2.50mm (.098”) / 3.00mm (.118”) Pitch Wir -to-Board F mal Crimp T rminal

Doc No: ATS-638235200 R l as Dat : 06-17-10 UNCONTROLLED COPY Pag 5 of 7

R vision: A R vision Dat : 06-17-10

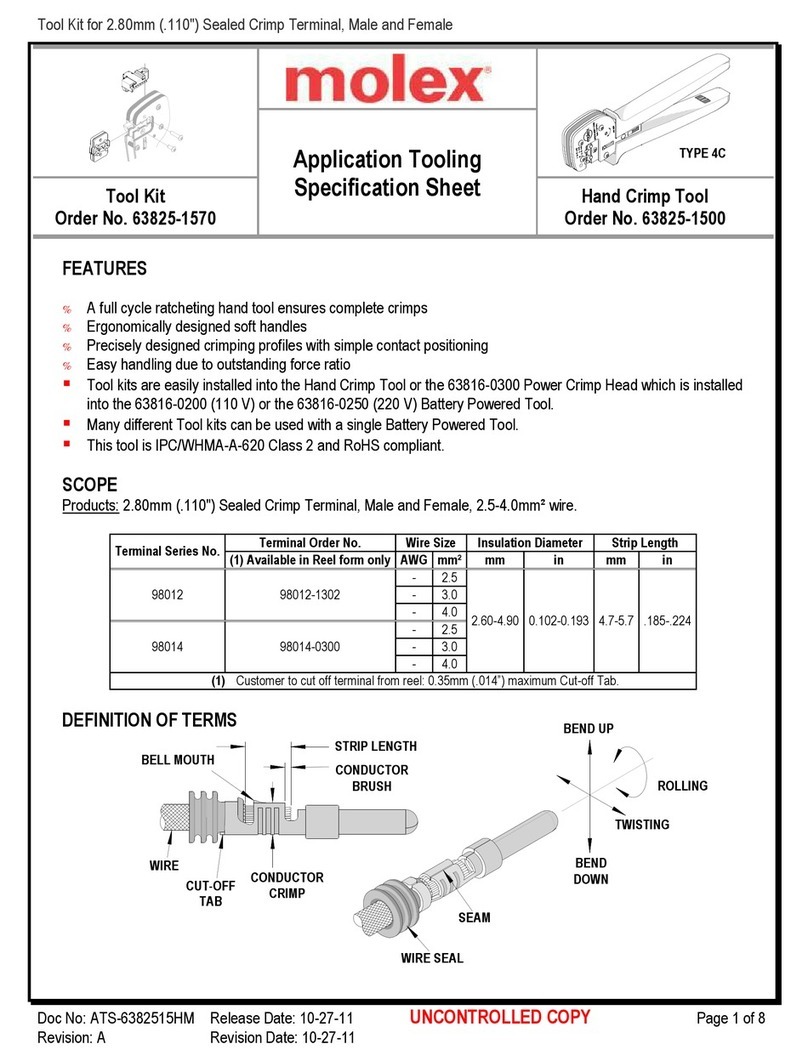

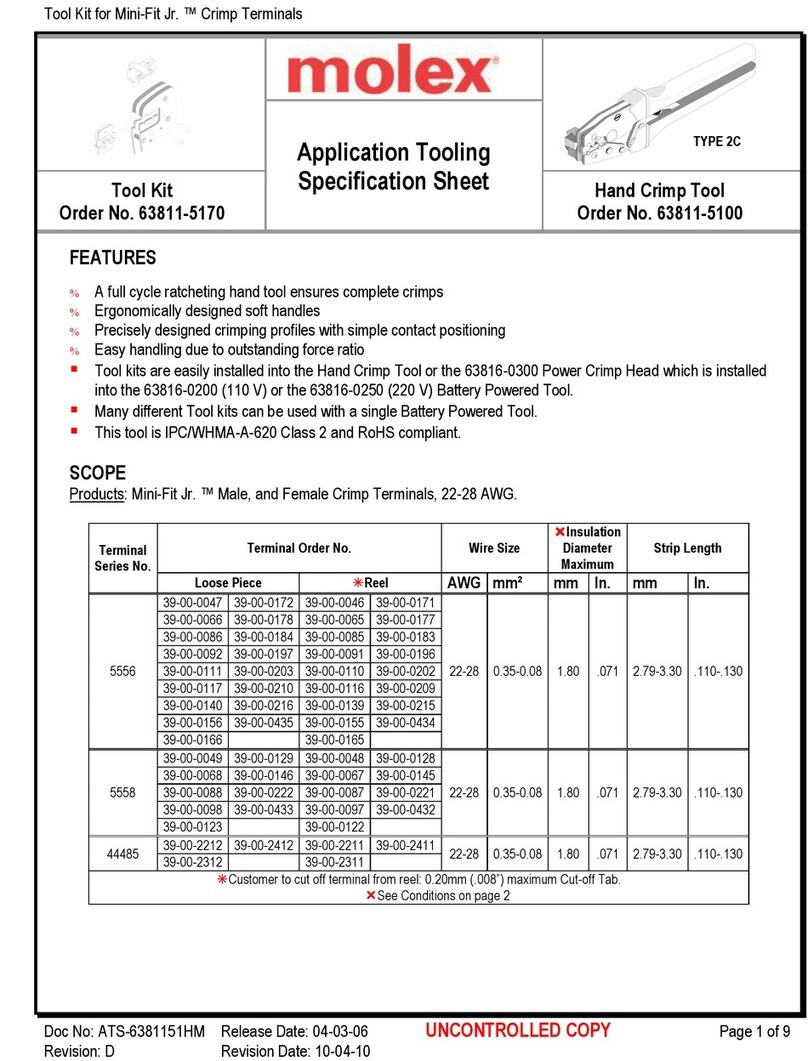

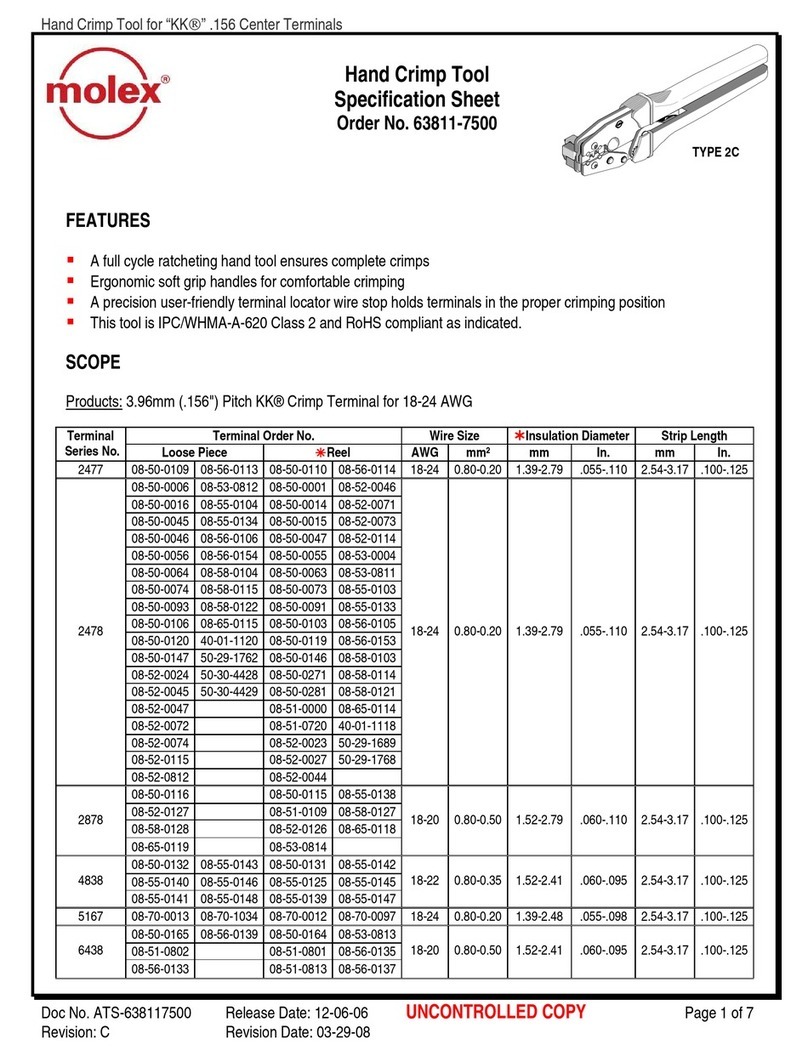

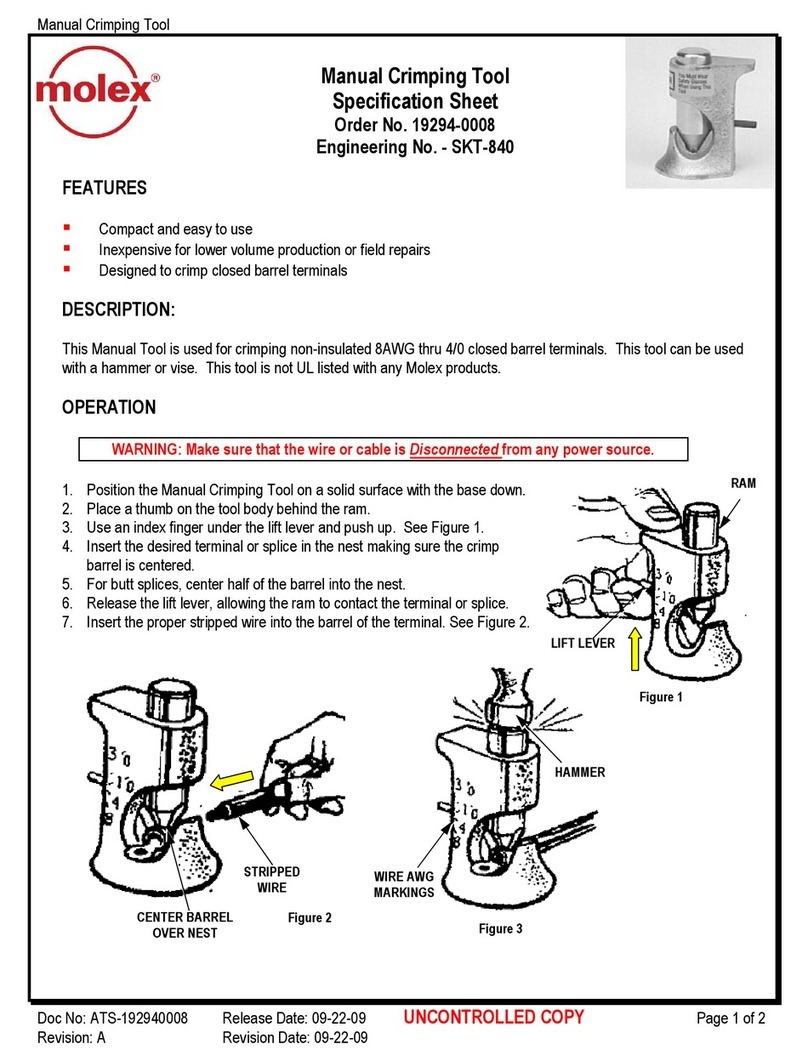

Figure 12

SQUEEZE

THE LINK IN

THE HANDLE

HOLD THE HAND

TOOL IN POSITION

SETTING

WHEEL

RATCHET

RELEASE LEVER

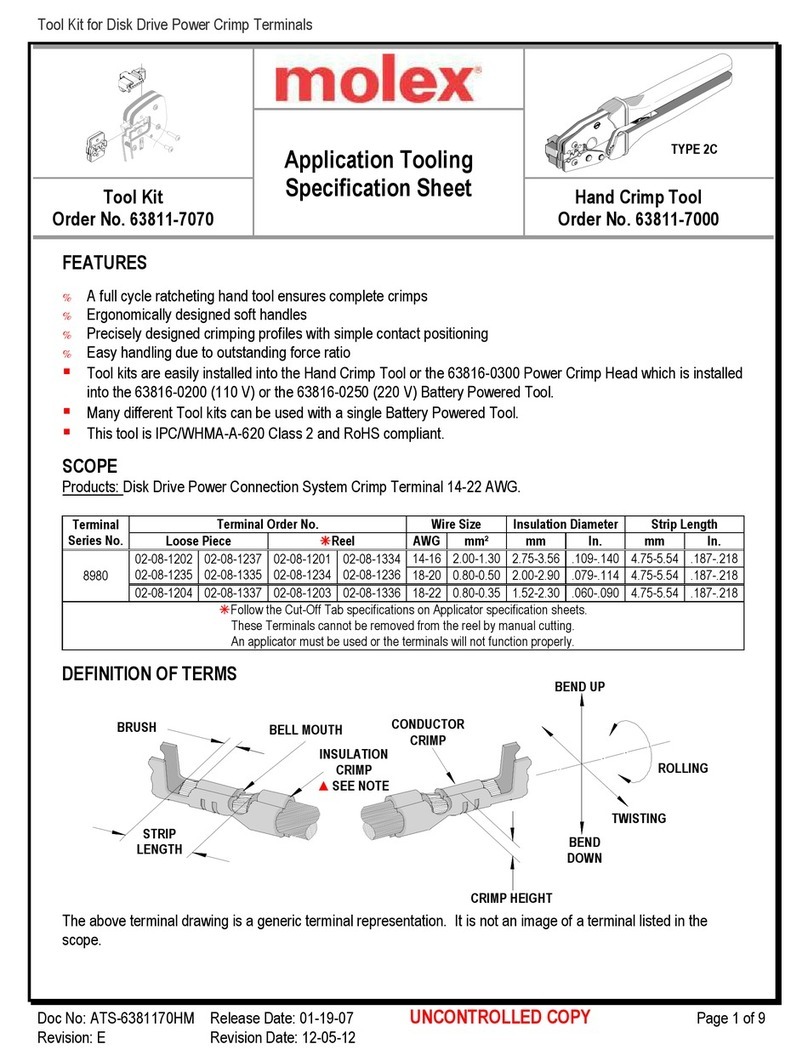

3. Flip th upp r tooling to th opposit sid and r plac th M3 BHCS Mak sur th small markings on th

front and back of th hand tool

fram match up and ar on th

outsid of th hand tool fram .

S Figur 8 and 9.

4. Do th sam thing with th low r

tooling and tight n th M3

scr ws. B sur th small

markings lin up.

5. R install th locator by following

th Instructions in th locator

r plac m nt s ction.

Maintenance

It is r comm nd d that ach op rator

of th tool b mad awar of, and r sponsibl for, th following maint nanc st ps:

1. R mov dust, moistur , and oth r contaminants with a cl an brush, or soft, lint fr cloth.

2. Do not us any abrasiv mat rials that could damag th tool.

3. Mak c rtain all pins; pivot points and b aring surfac s ar prot ct d with a thin coat of high quality machin

oil. Do not oil xc ssiv ly. Th tool was ngin r d for durability but lik any oth r quipm nt it n ds

cl aning and lubrication for a maximum s rvic lif of troubl fr crimping. Light oil (such as 30 w ight

automotiv oil) us d at th oil points,

v ry 5,000 crimps or 3 months, will

significantly nhanc th tool lif .

4. Wip xc ss oil from hand tool,

particularly from crimping ar a. Oil

transf rr d from th crimping ar a

onto c rtain t rminations may aff ct

th l ctrical charact ristics of an

application.

5. Wh n tool is not in us , k p th

handl s clos d to pr v nt obj cts from

b coming lodg d in th crimping di s,

and stor th tool in a cl an, dry ar a.

Miscrimps or Jams

Should this tool v r b com stuck or

jamm d in a partially clos d position, Do Not forc th handl s op n or clos d. Th tool will op n asily by

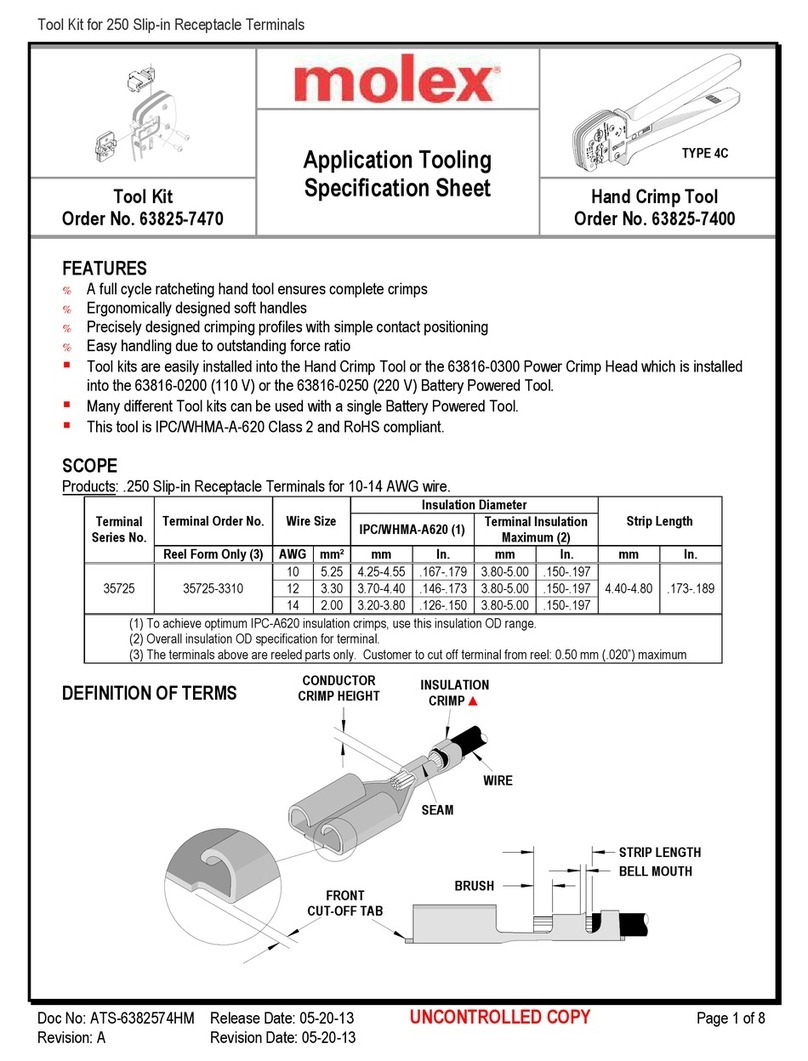

pr ssing up on th ratch t r l as l v r in th movabl handl . S Figur 11

How to Adjust Tool Preload

(See Figure 12)

This hand tool is factory pr s t to 25-45 LBS. pr load. It may b n c ssary ov r th lif of th tool to adjust tool

handl pr load forc . List d b low ar th st ps r quir d to adjust th crimping forc of th hand tool to obtain

prop r crimp conditions:

RATCHET RELEASE

LEVER

Figure 11

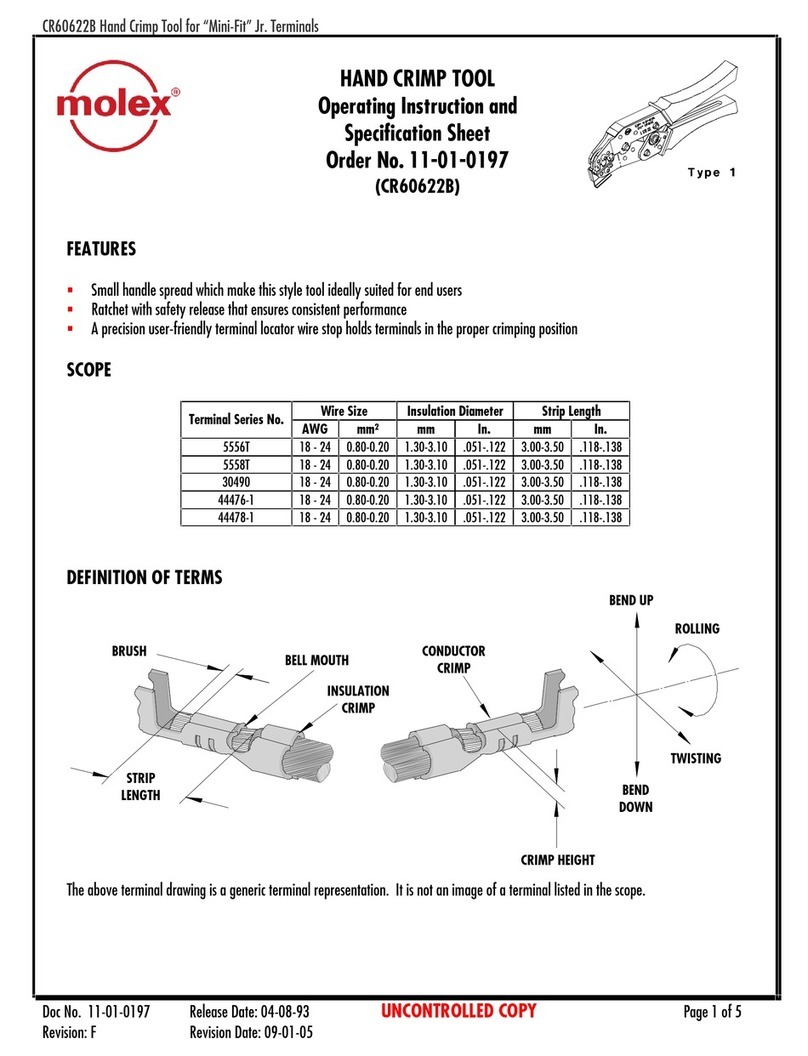

LUBRICATION POINTS

(BOTH SIDES) LIGHT OIL

(EVERY MONTHS OR

5,000 CRIMPS)

Figure 10