Hand Crimp Tool For Standard .062" Pin and Socket Crimp Terminals

Doc No: ATS-6 8191 00 Release Date: 01-22-08 UNCONTROLLED COPY Page 6 of 9

Revision: F Revision Date: 08- 1-12

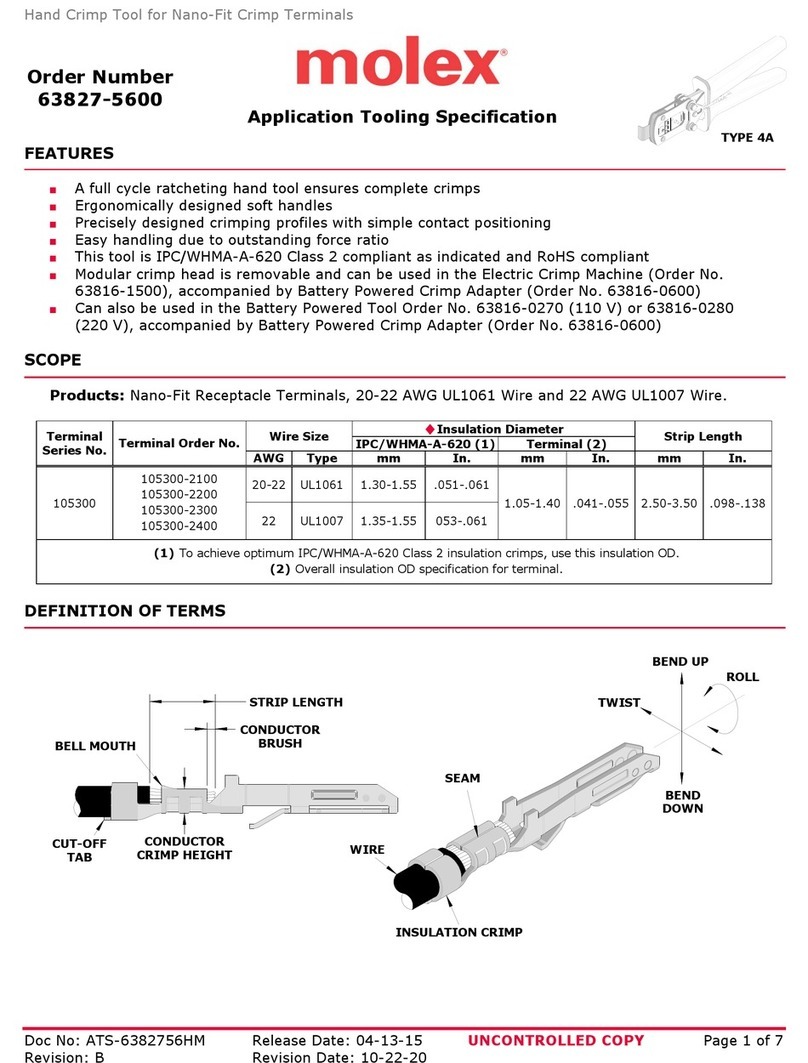

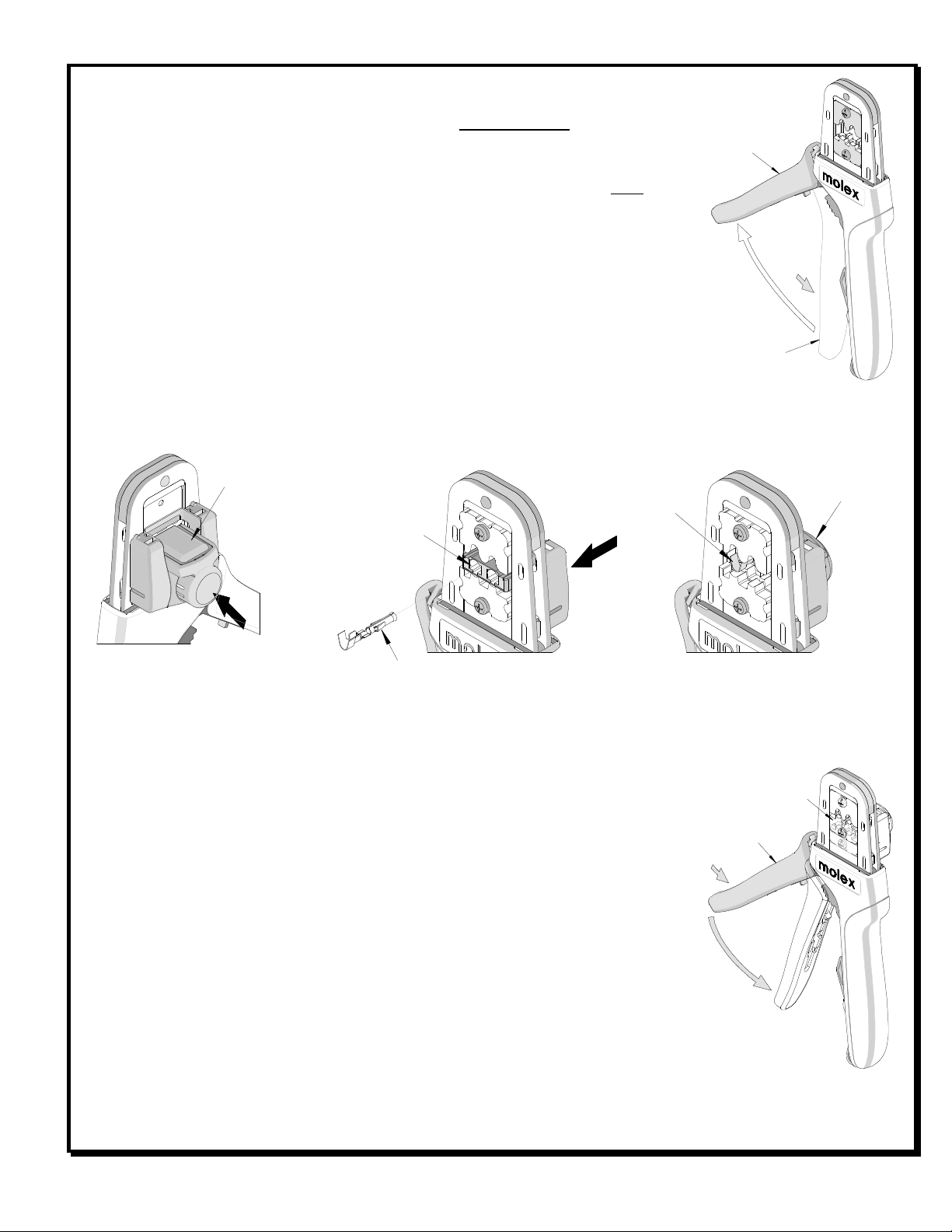

1. Open the crimp hand tool.

2. Squeeze gently on the lower area shown in Figure

7A with your thumb and index finger. The lower tabs

of the locator should disengage from the hand tool.

. Lift and pull away from the hand tool. The top

locator hooks should slip out of the top slots easily.

See Figure 7A.

4. To reinstall the new locator, make sure the hand tool

is in the open position.

5. Press the red insert down as far as it will go as

shown in Figure 7B.

6. Holding onto the lower part of the locator with your thumb and index finger, insert the locator top hooks (2) into

the hand tool top slots.

7. Rotate the locator down and press the lower tabs into the two bottom slots of the hand tool. To secure the

locator into place, the lower tabs must snap into place on the hand tool frame.

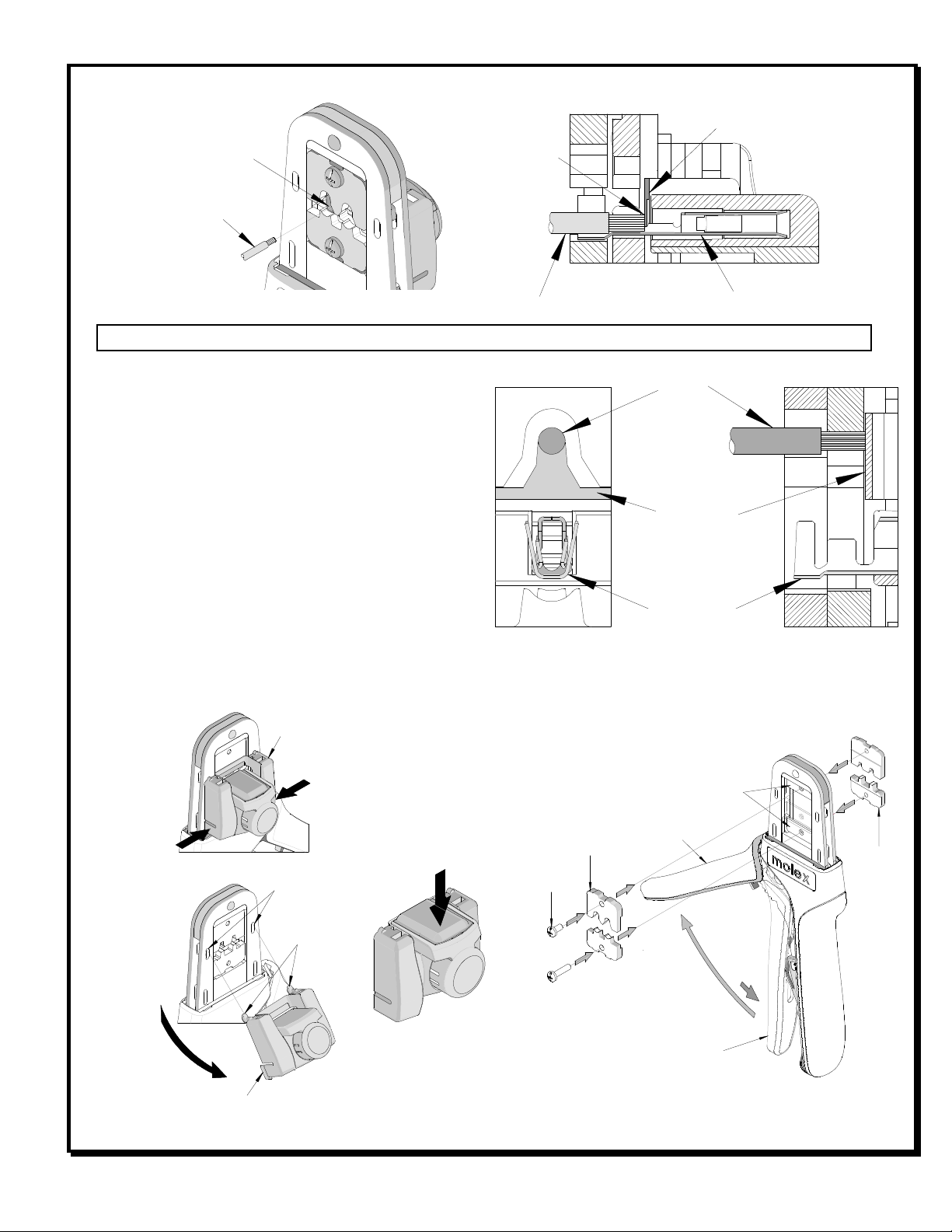

Right or Left Hand Operation

This hand tool has an added feature that can be converted from a right handed

application to a left handed application. It is necessary to reverse the tooling

along with the locator if using the left handed application. Follow the steps

below:

1. The locator must be removed before reversing the tooling.

2. Remove the M BHCS which is holding the upper tooling.

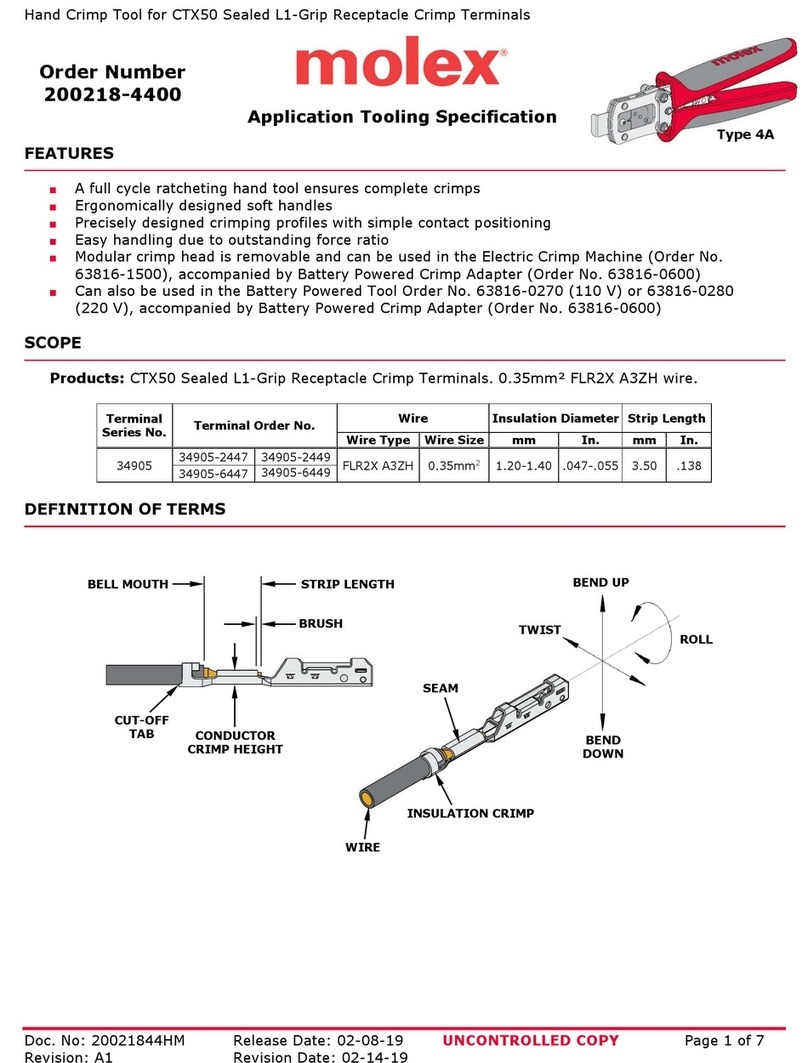

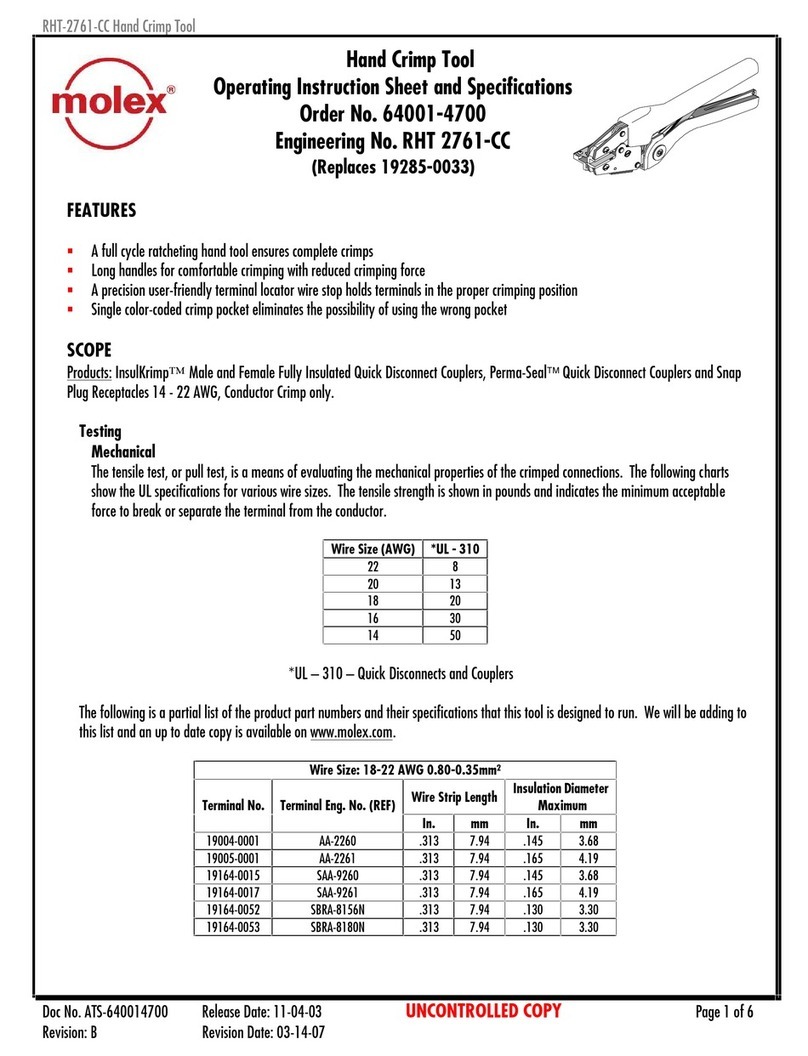

. Flip the upper tooling to the opposite side and replace the M BHCS Make

sure the small markings on the front and back of the hand tool frame match

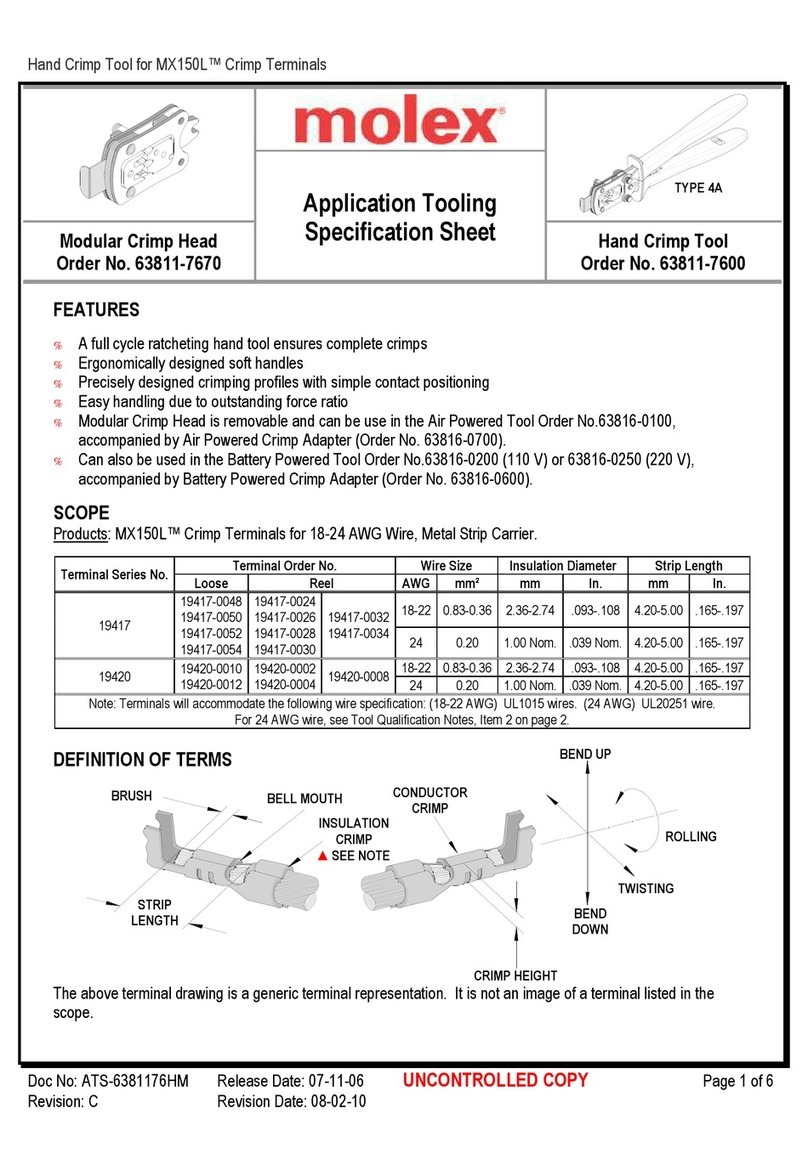

up and are on the outside of the hand tool frame. See Figure 8 and 9.

4. Do the same thing with the lower tooling and tighten the M screws. Be

sure the small markings line up.

5. Reinstall the locator by following the Instructions in the locator replacement section.

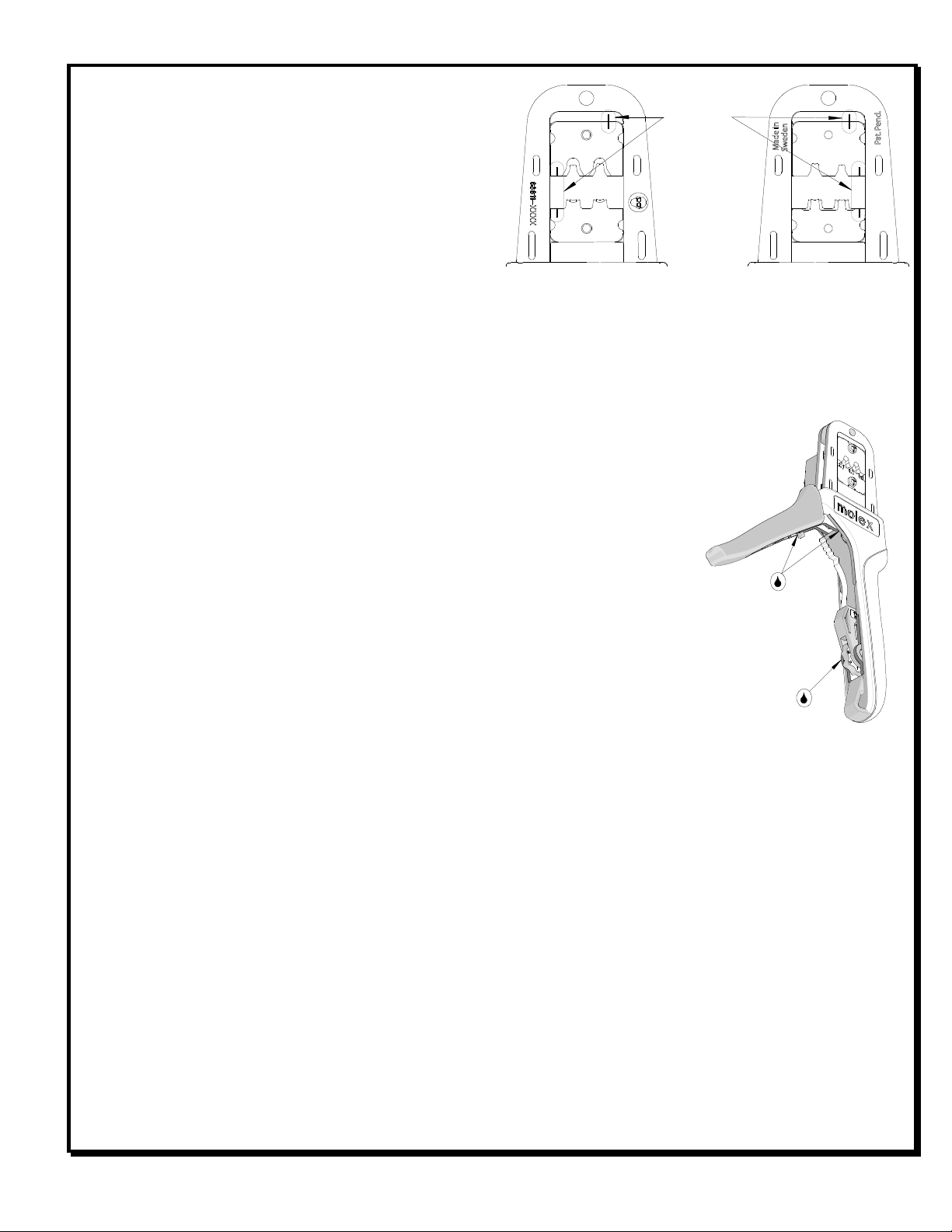

Maintenance

It is recommended that each operator of the tool be made aware of, and responsible for, the following maintenance

steps:

1. Remove dust, moisture, and other contaminants with a clean brush, or soft, lint free cloth.

2. Do not use any abrasive materials that could damage the tool.

. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high quality machine

oil. Do not oil excessively. The tool was engineered for durability but like any other equipment it needs

cleaning and lubrication for a maximum service life of trouble free crimping. Light oil (such as 0 weight

automotive oil) used at the oil points, every 5,000 crimps or months, will significantly enhance the tool life.

4. Wipe excess oil from hand tool, particularly from crimping area. Oil transferred from the crimping area onto

certain terminations may affect the electrical characteristics of an application.

5. When tool is not in use, keep the handles closed to prevent objects from becoming lodged in the crimping dies,

and store the tool in a clean, dry area.

(BOTH SIDES) LIGHT OIL

(EVERY 3 MONTHS OR

5,000 CRIMPS)

UP MARKS

FRONT

Figure 9