CR60670B Hand Crimp Tool for “Mini-Fit Jr. ”Terminals

Doc No. 11-01-0199 Release Date: 11-04-93UNCONTROLLED COPY

Page 4 of 6

Revision: E Revision Date: 09-01-05

Maintenance

It is recommended that each operator of

the tool be made aware of, and

responsible for, the following

maintenance steps:

1. Remove dust, moisture and other

contaminants with a clean brush, or

soft, lint free cloth.

2. Do not use any abrasive materials

that could damage the tool.

3. Make certain all pins; pivot points and

bearing surfaces are protected with a

thin coat of high quality machine oil.

Do not oil excessively.

4. When tool is not in use, keep the

handles closed to prevent objects

from becoming lodged in the crimping

dies, and store the tool in a clean, dry

area.

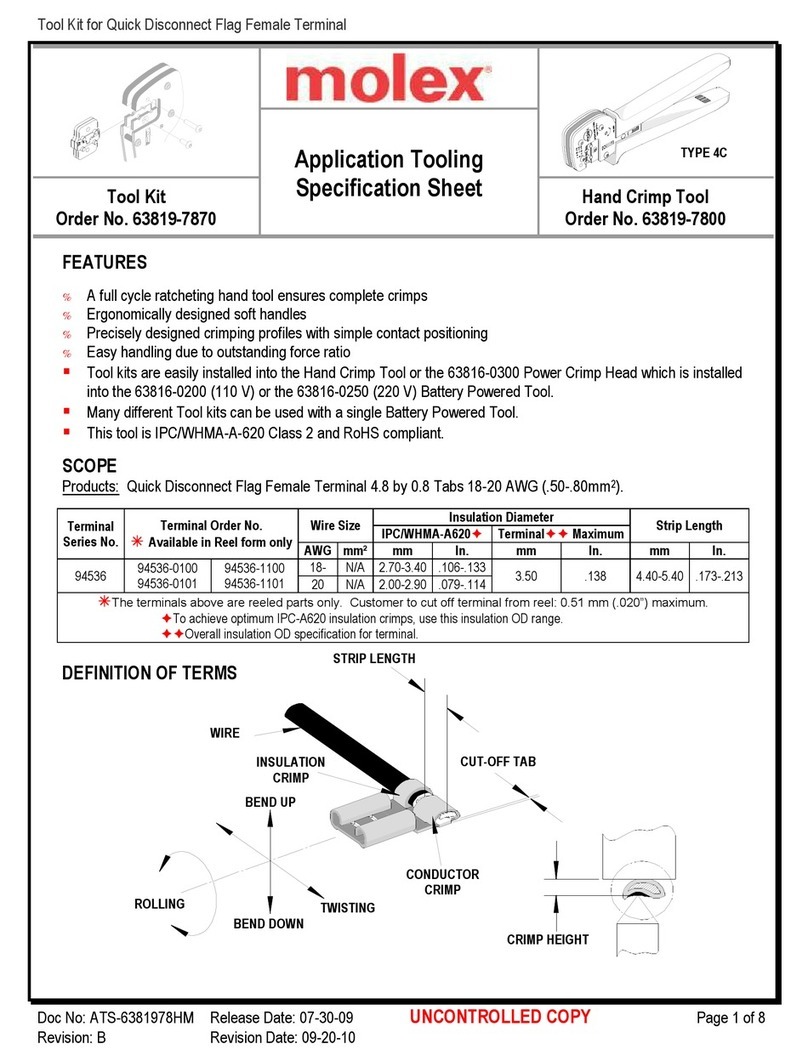

Miscrimps or Jams

Should this tool ever become stuck or

jammed in a partially closed position, Do

Not force the handles open or closed.

The tool will open easily by lifting the

ratchet release lever (See Figure 4).

How To Adjust Tool Crimp Force

(See Figure 4)

It may be necessary over the life of the

tool to adjust tool-crimping force. Listed

below are the steps required to adjust

the crimping force of the hand tool to

obtain proper crimp conditions:

1. Remove the screw and plastic cover

washer. Note the setting wheel position.

2. Lift the setting wheel off the axle.

Turn the eccentric axle with a

screwdriver.

3. Turning the eccentric axle counter-

clockwise will increase handle force.

4. Replace the setting wheel to the axle,

aligning the nearest notch in the setting

wheel to the dowel pin.

5. Replace the plastic cover washer and

screw.

6. Check to the crimp specifications

after tool crimp force is adjusted.

Warranty

This tool is for electrical terminal

crimping purposes only. This tool is

made of the best quality materials. All

vital components are long life tested. All

tools are warranted to be free of

manufacturing defects for a period of 30

days. Should such a defect occur, we

would exchange the tool free of charge.

This will not be applicable to altered,

misused, or damaged tools. This tool is

designed for hand use only. Any

clamping, fixturing, or use of handle

extensions voids this warranty.

Hand held crimping tools are intended for

low volume, prototyping, or repair

requirements only.

CAUTION: Repetitive use of this tool

should be avoided.

Notes:

1. This tool should only be used for the

terminals and wire gauges specified

on this sheet.

2. This tool is not adjustable for crimp

height, however crimp force is

adjustable (See instructions above).

Variations in tools, terminals, wire

stranding and insulation types may

affect crimp height.

3. This tool is intended for standard

conductor sizes. It may not give a

good insulation crimp support for all

insulation sizes.

4. Molex does not repair hand tools (see

warranty above) The replacement

parts listed are the only parts

available for repair. If the handles or

crimp tooling is damaged or worn, a

new tool must be purchased.