3 / 19

Table of Contents

1. Instruction ....................................................................................................................................4

1.1. Product description................................................................................................................... 4

1.2. Conformity ................................................................................................................................ 4

1.3. Dealing with the operating instruction ....................................................................................... 4

2. Safety...........................................................................................................................................5

2.1. Warning and Safety instructions................................................................................................ 5

2.2. General safety instructions........................................................................................................ 6

2.3. Responsibilities ......................................................................................................................... 6

2.4. Intended use............................................................................................................................. 7

2.5. Predictable misuse ................................................................................................................... 7

2.6. Hazardous area ........................................................................................................................ 8

3. Delivery ........................................................................................................................................8

3.1. Packing .................................................................................................................................... 8

3.2. Scope of delivery ...................................................................................................................... 8

4. Technical description ....................................................................................................................9

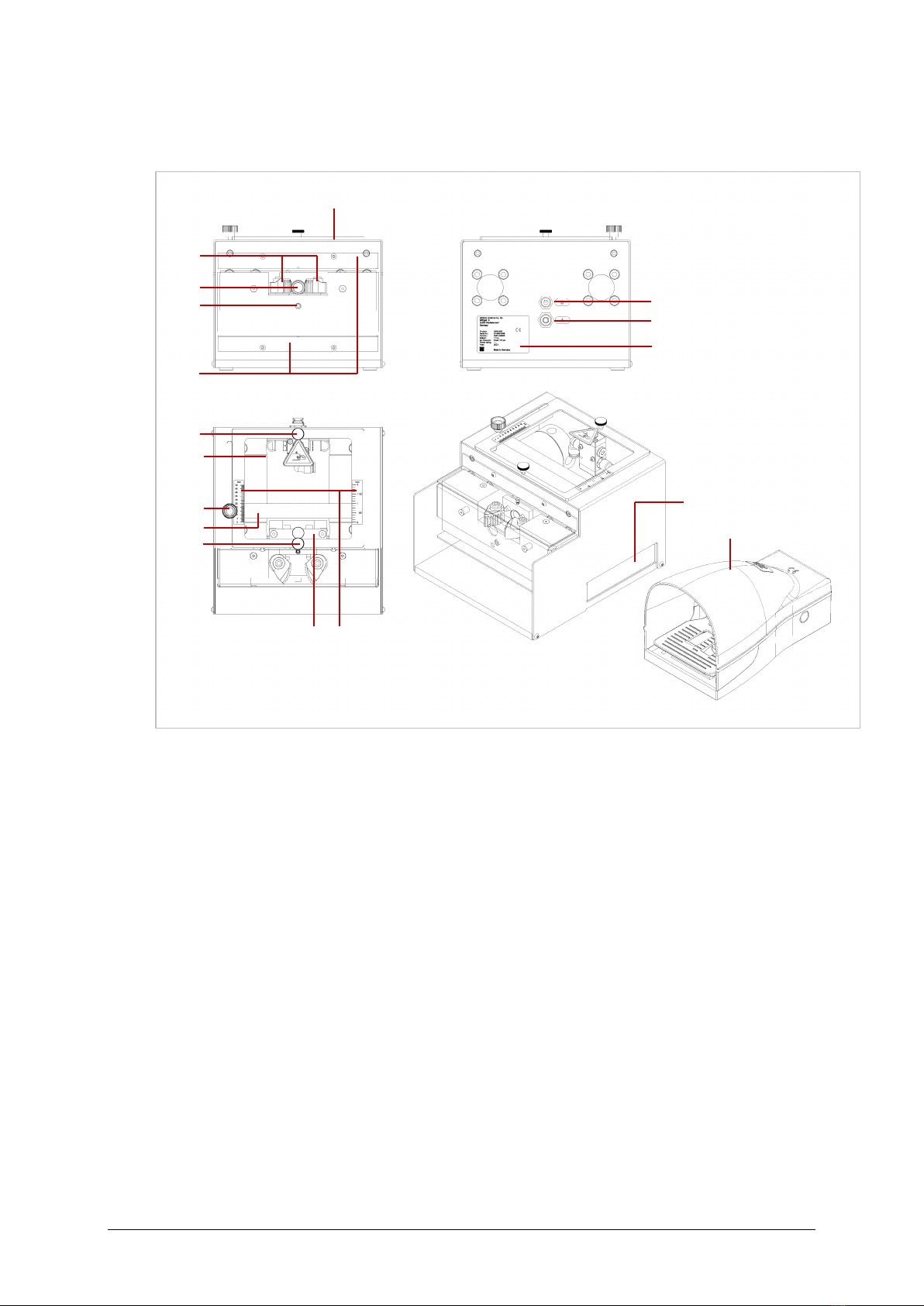

4.1. Machine overview ..................................................................................................................... 9

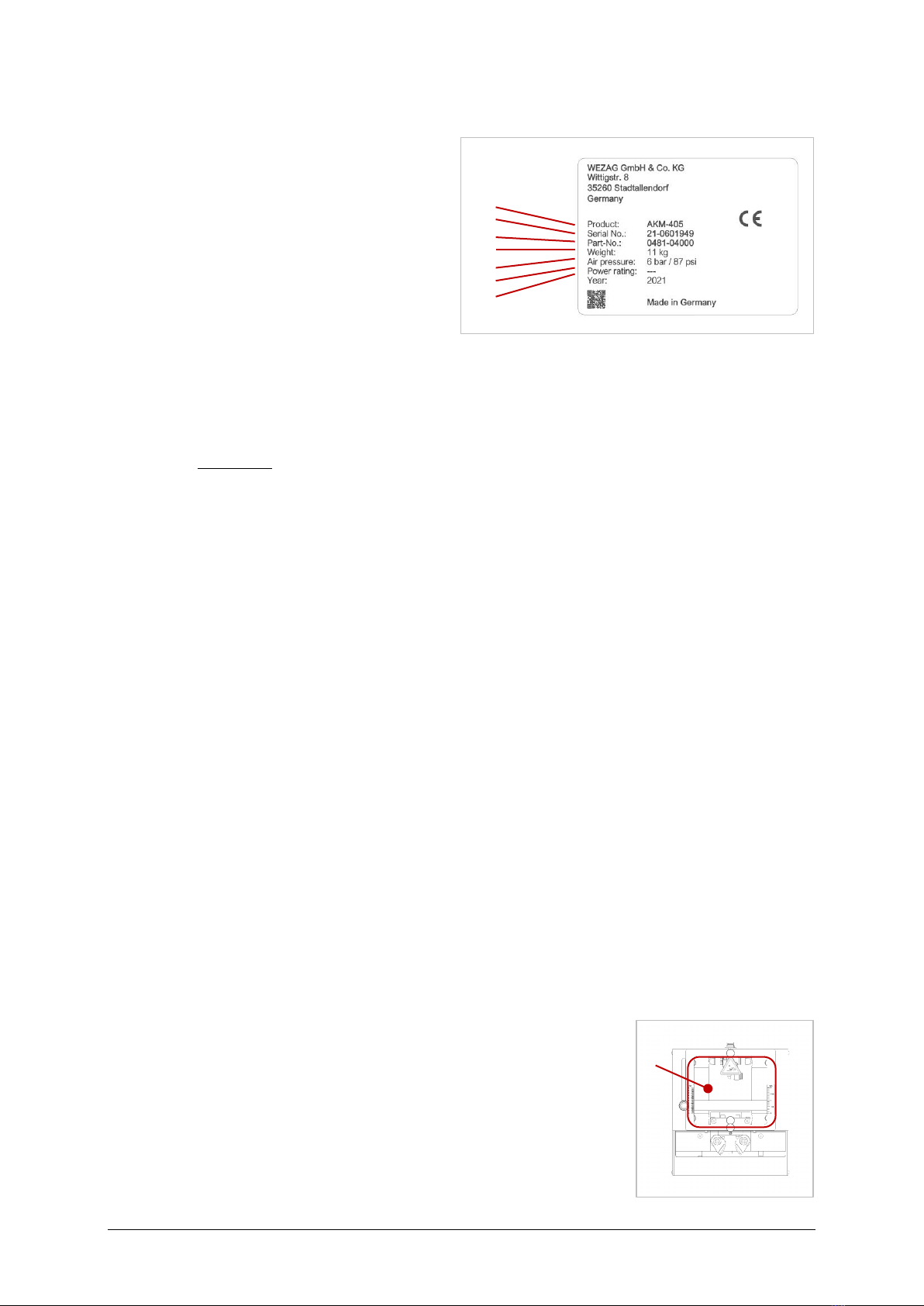

4.2. Machine identification ............................................................................................................. 10

4.3. Technical date ........................................................................................................................ 10

4.4. Functional and operating elements ......................................................................................... 10

4.4.1. Safety cover.................................................................................................................... 10

4.4.2. Stripping length............................................................................................................... 11

4.4.3. Knife opening.................................................................................................................. 11

5. Transport, Storage......................................................................................................................11

5.1. Transport................................................................................................................................ 11

5.2. Storage................................................................................................................................... 11

6. Assembly and Connection ...........................................................................................................12

6.1. Assembly................................................................................................................................ 12

6.2. Connection ............................................................................................................................. 13

7. Setting up / Changeover..............................................................................................................13

7.1. Equipment .............................................................................................................................. 13

7.2. Change centering guide bushes ............................................................................................. 14

7.3. Converting the knife................................................................................................................ 15

8. Production operation...................................................................................................................16

9. Maintenance / Service.................................................................................................................17

9.1. Maintenance plan ................................................................................................................... 17

9.1.1. Daily ............................................................................................................................... 17

9.1.2. Weekly............................................................................................................................ 17

10. Troubleshooting and fault analysis ...........................................................................................18

11. Decommissioning, Dismantling, Disassembly ...........................................................................18

12. Disposal.................................................................................................................................19

13. Accessories overview .............................................................................................................19

14. Repair ...................................................................................................................................... 19