FA2 Applicator

Doc. No: TM-638080200 Release Date: 02-08-18 UNCONTROLLED COPY Page 5 of 33

Revision: B2 Revision Date: 05-04-18

Table of Contents

Safety Warnings and Information ..................................................................................................................................3

Section 1 –General Description....................................................................................................................................6

1.1 Description.................................................................................................................................................6

1.2 Features ....................................................................................................................................................6

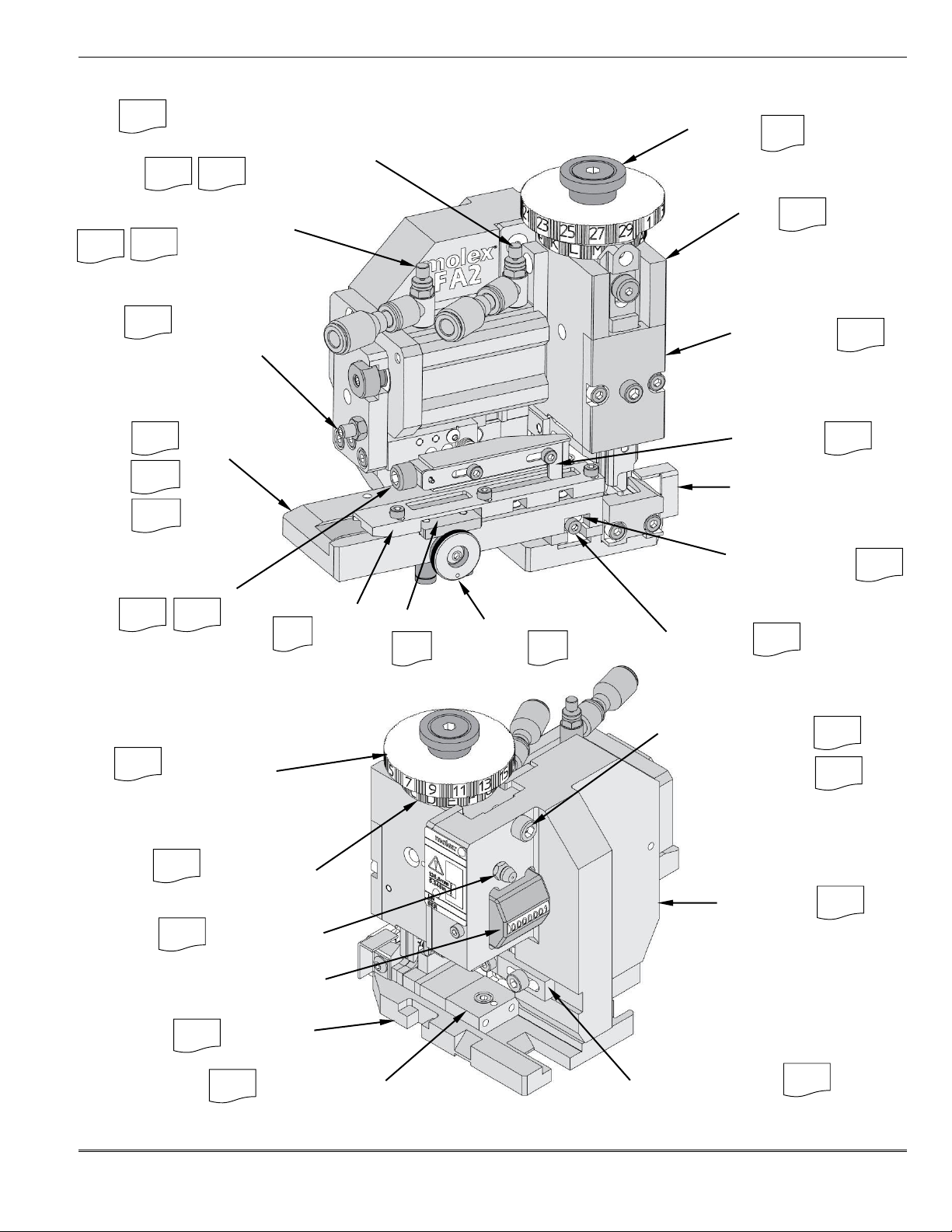

1.3 General Applicator Parts Identification (Mechanical Feed)........................................................................7

1.4 General Applicator Parts Identification (Air Feed)......................................................................................8

1.5 Applicator Tooling Identification.................................................................................................................9

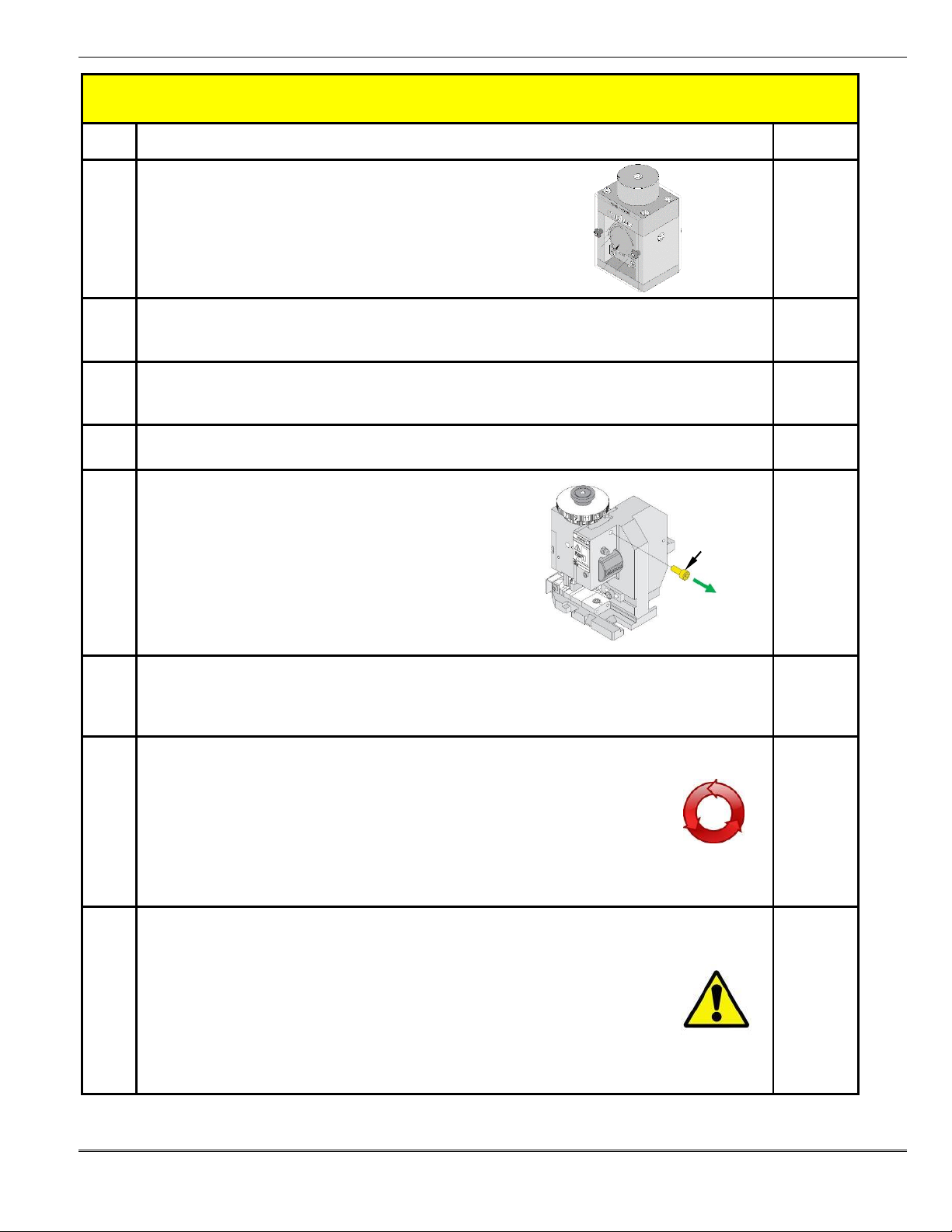

Section 2 –Start-Up Guide..........................................................................................................................................10

Section 3 –Troubleshooting........................................................................................................................................12

3.1 Applicator Troubleshooting......................................................................................................................12

3.2 Crimp Troubleshooting ............................................................................................................................12

Section 4 –Setup and Operation.................................................................................................................................14

4.0 Press Shut Height....................................................................................................................................14

4.1 Applicator Installation and Removal ........................................................................................................14

4.2 How to Make a Crimp ..............................................................................................................................15

4.3 Crimp Height Adjustments.......................................................................................................................15

4.4 Track Guide Setup and Adjustment.........................................................................................................16

4.5 Loading and Unloading Terminals in the Applicator Track.......................................................................18

4.6 Terminal Feed Adjustments.....................................................................................................................19

4.7 Terminal Track Position Adjustment ........................................................................................................22

4.8 Crimp Tooling Installation and Removal ..................................................................................................23

4.9 Wire Stop Setup and Adjustment.............................................................................................................25

4.10 Wire Processing Setup and Feed Cam Orientation .................................................................................27

4.11 Bend Adjust Dial......................................................................................................................................28

Section 5 –Maintenance .............................................................................................................................................29

5.1 Cleaning ..................................................................................................................................................29

5.2 Lubrication...............................................................................................................................................29

5.3 Storage....................................................................................................................................................29

Section 6 –Service Parts ............................................................................................................................................30

6.1 Feed Pawl Spring Replacement ..............................................................................................................31

6.2 Accessories .............................................................................................................................................32

6.3 Contact Us...............................................................................................................................................32

Section 7 –Crimp Quality............................................................................................................................................33