RAST 5.0 Semi-Automatic Terminator Machine

Doc: No: ATS-623006100 Release Date: 04-2 -09 UNCONTROLLED COPY Page 5 of 65

Revision: A Revision Date: 04-2 -09

1.1 Descriptio

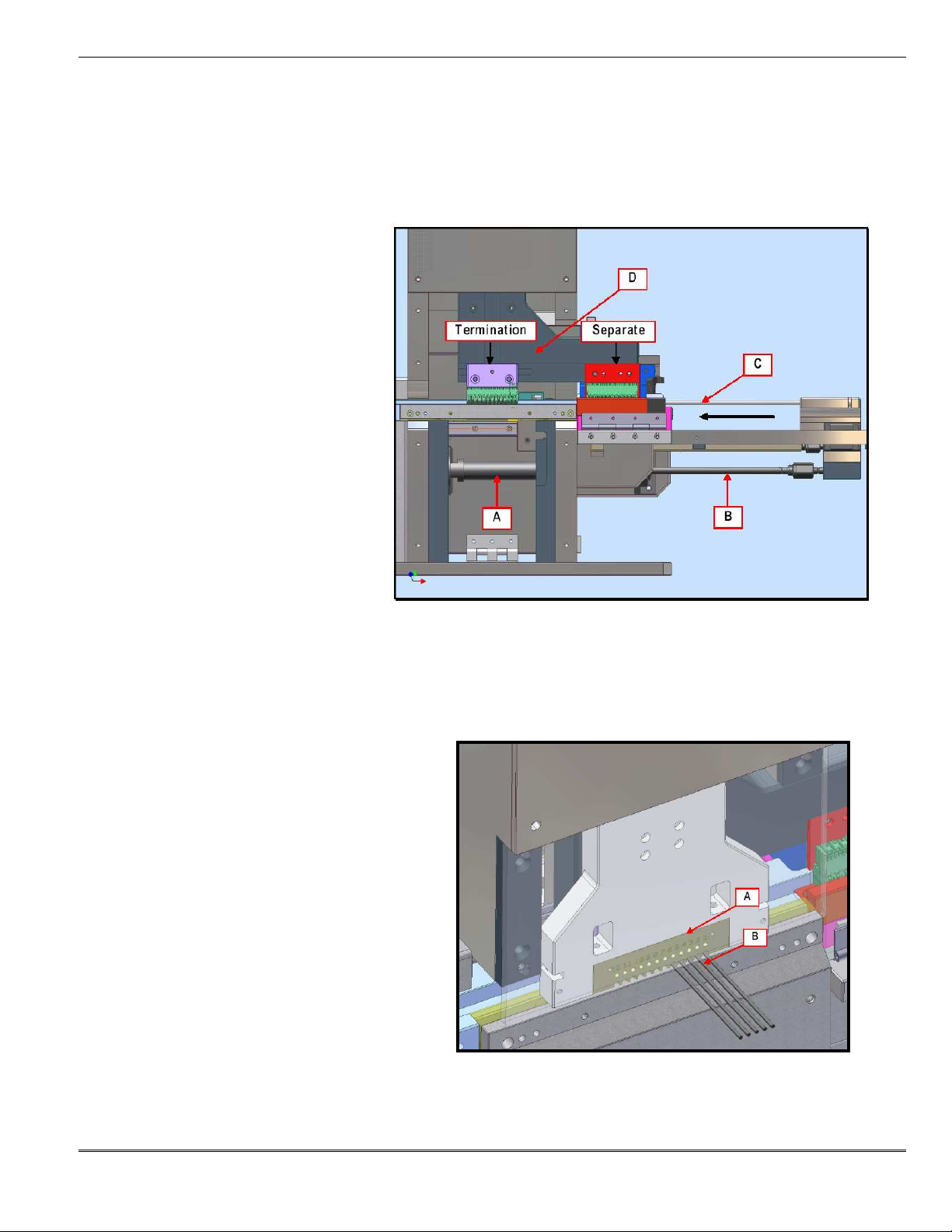

The 62300-6100 APPLI-MATE™ (RAST 5.0)

Semi-Automatic Terminator Machine, is designed

to terminate the APPLI-MATE™ (RAST 5.0)

female connector series (90 35, 91779, and

92000) onto discrete wire (1.0-1.5 mm2 and 16-1

AWG). This machine will accommodate circuit size

2 through 4.

1.2 Tech ical Specificatio s

Power Specificatio s:

To function correctly, these fixtures require the

following services:

Electrical Service

115/220 VAC 50/60 HZ 1 Phase 2 AMPS

P eumatic Service

6 BAR ( 5 psi) Minimum Clean, Dry and Filtered

Air Source

Pressure Gauge Setti gs

Main supply to machine - 6 BAR ( 5 psi)

1.3 Applicable Products A d Wires

Co ectors

Appli-Mate™ RAST 5.0 connector series 90 35,

91779, and 92000. See Connector Chart in

Section 6.

Wires

Conductor: 1.5mm², 1.0mm², 16AWG, and

1 AWG

Insulation outer diameter: 3.5mm maximum.

1.4 Delivery Check

Carefully remove this machine from its shipping

container and determine that the following items

are included in the package.

Order No.

62300-6100 Semi-Automatic Terminator

Machine for APPLI-MATE™

(RAST 5.0)

ATS-623006100 Instruction Manual

1.5 CE Complia ce

Complies with the ge eral health a d safety

requireme ts i accorda ce with:

-Council Directive 9 /37/EEC

-Council Directive 9/336/EEC and amended by 92/31/EEC

-Council Directive 73/23/EEC

This machi ery has bee desig ed a d

ma ufactured i accorda ce with the

followi g tra sposed harmo ised Europea

sta dards.

EN292: parts 1 and 2: 1991, Safety of Machinery-Basic

concepts, general principles for design.

EN294: 1992, Safety of Machinery-Safety distances to

prevent danger zones reached by the upper limits.

EN349: 1993, Safety of Machinery-Minimum gaps to avoid

crushing of parts of the human body.

EN41 : 1992, Safety of Machinery-Emergency stop

equipment, functional aspects- Principal for design.

EN60204 part 1: 1993, Safety of Machinery-Electrical

equipement of machines-Specification for general

requirements.