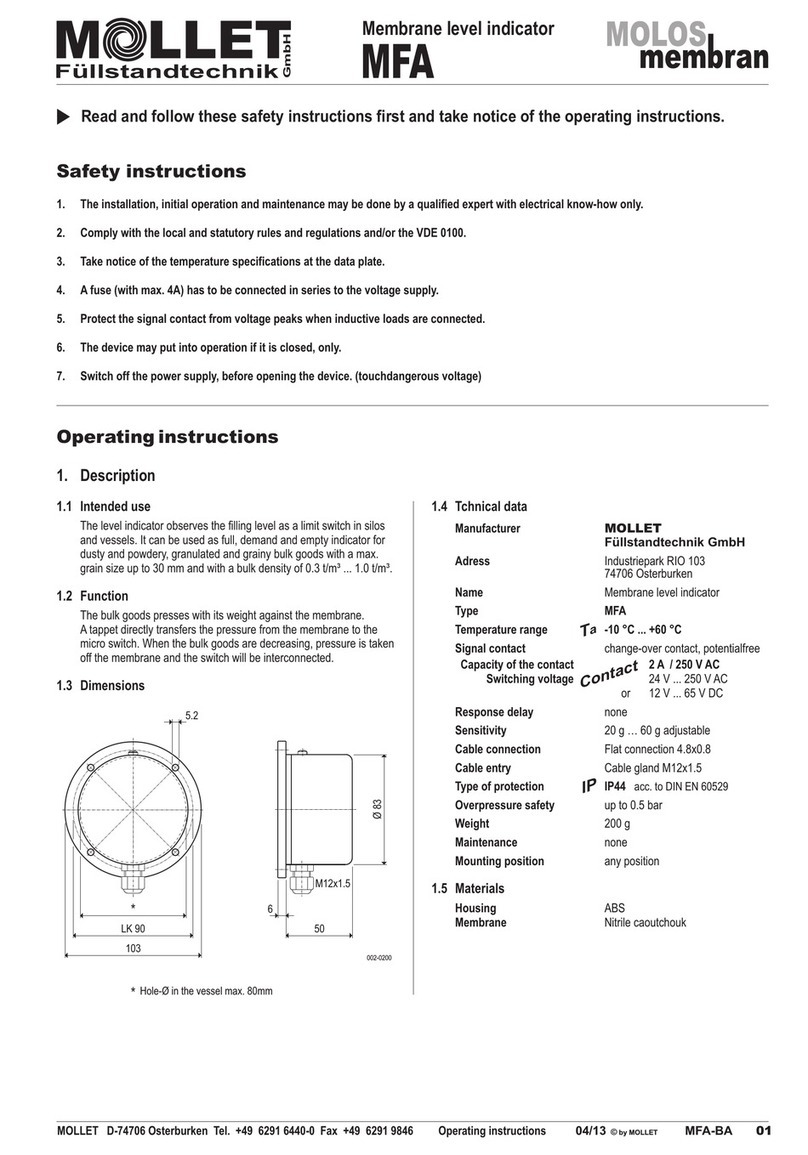

+

-

light

Works setting medium

strong

Spring arm

As occasion demands, the sensitivity of the level

indicator can be adjusted, referring to the characteristics

of the bulk goods, by shifting the spring arm.

5. Setting of the sensitivity

-

+

7. Maintenance and servicing

- Damaged parts, contacts or connections have to be

repaired immediately or being replaced with parts of

the same kind.

- Please ensure that the shaft of level indicators with

jib extension will not be buckled or bended.

- Violation against applicable law and standards.

7.1 Maintenance

6.3 Inexpert handling

- In case of intended use, the rotary blade level

indicator needs no maintenance.

- Remove, adding or change of assembling parts,

unless this has been described in the documents of

the manufacturer.

- Remove deposits and stickings from the blades or

wrinkles with a brush or with a scraper.

Don´t use any force and don´t damage the sealring

of the shaft.

8. Storage

- While storage, the level indicator has to be

protected from dust and humidity.

- The level indicator can be recycled.

7.2 Servicing

- Mounting of spare parts which are no original parts.

- The disposal applies to the valid environmental

guidelines according to the location of the carrier

and the local manufacturing conditions.

- Ignoring of the safety instructions and the operating

instructions.

- Inspect the assemblings inside of the container

about signs of wear and tear, in regular intervals.

Define the intervals of the control, depending on the

bulk goods characteristics.

- U the rotary blade level indicator in not

intended use.

tilization of

- Until the complete restoration of the proper function,

the rotary blade level indicator must not be used

any more.

9. Disposal

- Commissioning of the rotary blade level indicator

only, if the installation will be done correctly and if it

will be fixed tightly with the electrical contact.

6.2 Normal operation

6. Utilization

6.1 Putting into operation

- Operate the level indicator within the intended

temperature ranges for the ambient and bulk goods

temperature.

- Protect the inside of the control head from soiling.

- When the indicator has to be damaged, you have to

take the device out of operation immediately.

- During operation, the housing and the cable entry

must be closed tightly.

- Use the rotary blade level indicator in its intended

only. application

M LLET

Füllstandtechnik

DF30

12/19 DF30-BA

©

by MOLLET

05

MOLLET D-74706 Osterburken Tel. +49 6291 6440-0 Fax +49 6291 9846 Operating instruction

Three settings are possible:

1. light

for very light bulk goods

2. medium

suitable for almost all bulk goods

Fluidised bulk goods are lighter during filling and

draining process. This has to be taken appropriately

into consideration when setting the spring force and

selecting the size of the measuring blade.

3. strong

for sticking bulk goods

Rotary blade level indicator

Level limit switch for bulk goods

001-0229