Microwave level measurement

MWF

04 MWF-BA-04 03/20 © by MOLLET

M LLET

Füllstandtechnik

GmbH

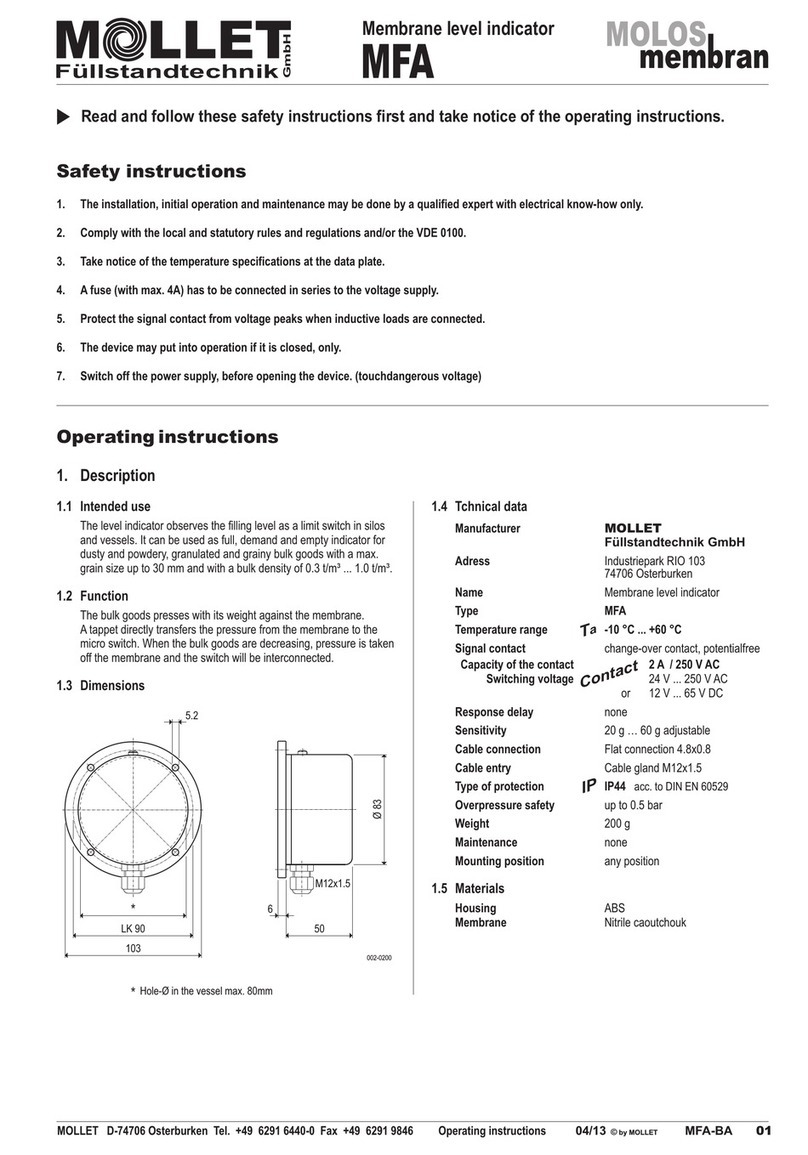

Tensioning weight Stainless steel 1.4571 / 316 Ti

Material Housing A1 Aluminium, coated RAL 7001

Connecting sleeve Stainless steel 1.4571 / 316 Ti

Rod probe Ø 6 mm

Flange F1 F70 1.4571 / 316 Ti or Aluminium

Wire rope Stainless steel 1.4401 / 316

Rod Stainless steel 1.4571 / 316 Ti

Hexagon nut G3 stainless steel 1.4571 / 316 Ti else

stainless steel 1.4301 / 304

Probe length [LS] 1.0 m ... 20.0 m

Tolerance of the lenghth [L] ± 10 mm

Feed-through PEEK

Process connection Stainless steel 1.4571 / 316 Ti

Flange F2 F100 1.4301 / 304 or Aluminium

8. Technical data

Housing A2 Stainless steel 1.4408 / 316

Probe length [LW] 0.5 m ... 3.0 m

Wire rope probe Ø 6 mm with tensioning weight Ø 30 mm

20 mA / 100 %

Depending on probe length

120

Reference point [R]

Sealing face of the thread

Inactive area

Adjustable

150

Probe length [L]

Maximum measuring range

Measuring range [M] 0 ... 100 %

Inactive area

Adjustable

Switch-points freely positionable

inside the measuring range [M]

4 mA / 0 %

Top edge tensioning weightFactory setting

002-1001

up to 5.0 m at 0.4 m

up to 10.0 m at 0.6 m

up to 15.0 m at 0.8 m

Factory setting [oMG] 20 mA depending on probe length for bulk

goods:

up to 20.0 m at 1.0 m

Inactive area wire rope rod

Measuring range (analog) [M] 4 mA lower current value [uMG]

down 150 mm 10 mm

Probe length [L] Reference point [R] to end of probe

up 120 mm 120 mm

10. Technical measuring data

max. measuring range < probe length

20 mA upper current value [oMG]

Factory setting [uMG] 4 mA Top edge tensioning weight

up to 3.0 m at 0.3 m

of filling level <1 m/s

or max. 0.03 % of measured value

or depending on customers request

Measureable changes

Repeatability <2 mm

Switch-points [oSA] [uSA] freely positionable inside measuring

(digital) range [M] with switch-hysteresis

Factory setting at 20% of probe length [L] below [R]

- upper and lower switch-point freely

selectable

Measuring accuracy ±3 mm

beneath reference point [R]

- minimum distance 3 mm

Temperature drift <0.2 mm/K

Resolution <1 mm (at reference conditions)

9. Electrical data

Supply voltage U 12 ... 30 V DC

N

(reverse-polarity protected)

Analog output signal (active) I 4 ... 20 mA (0 ... 100 %)

N

Switching output U 0 ... U

SN

Cable entry Cable gland M20x1.5

HIGH = U -2 V, LOW = 0 V ... 1 V

N

Load current <200 mA

Connection clamps 0.5 - 2 mm², screwless

Protection class I [

Power consumption <70 mA bei 24 V DC (no burden)

Type of protection IP66 and in vessel intrinsically safe „ia“

DC PNP (active)

NC or NO (selectable)

Factory setting NC

Response time <100 ms

Start-up time <6 sec

IP

Supply

Output

Contact

Operating instruction MOLLET D-74706 Osterburken Tel. +49 6291 6440-0 Fax +49 6291 9846

20 mA [oMG]

Upper switch-

point [oSA]

Filling level [F]

4 mA [uMG]

Lower switch-

point [uSA]