[

M LLET

Füllstandtechnik

GmbH

02 PF-BA 02/20 © by MOLLET

Operating instructions MOLLET D-74706 Osterburken Tel. +49 6291 6440-0 Fax +49 6291 9846

2.1 Preparation

- Sensor (Cone)

The delivery consists of:

switching point.

- Inspect if the delivery is complete.

- The pendulum has not to be struck by the filling stream.

- The pendulum must be able to swing unimpeded up to the

- Read and follow the safety instructions and the operating

2. Installation

- Housing with buckling protector

- Rod with 2 locking nuts

instructions, before handling with the device !

- If the pendulum has to be mounted from the inside of the vessel,

2.4 Electrical connection

than screw at first the housing at the connection flange and mount

2.3 Mounting in the vessel

2.5 Cable gland

- Screw the cap nut, until the cable entry is closed tightly.

measuring cone and counter the nut with no. 13 open jaw wrench.

Position the level indicator with the gasket at the provided flange

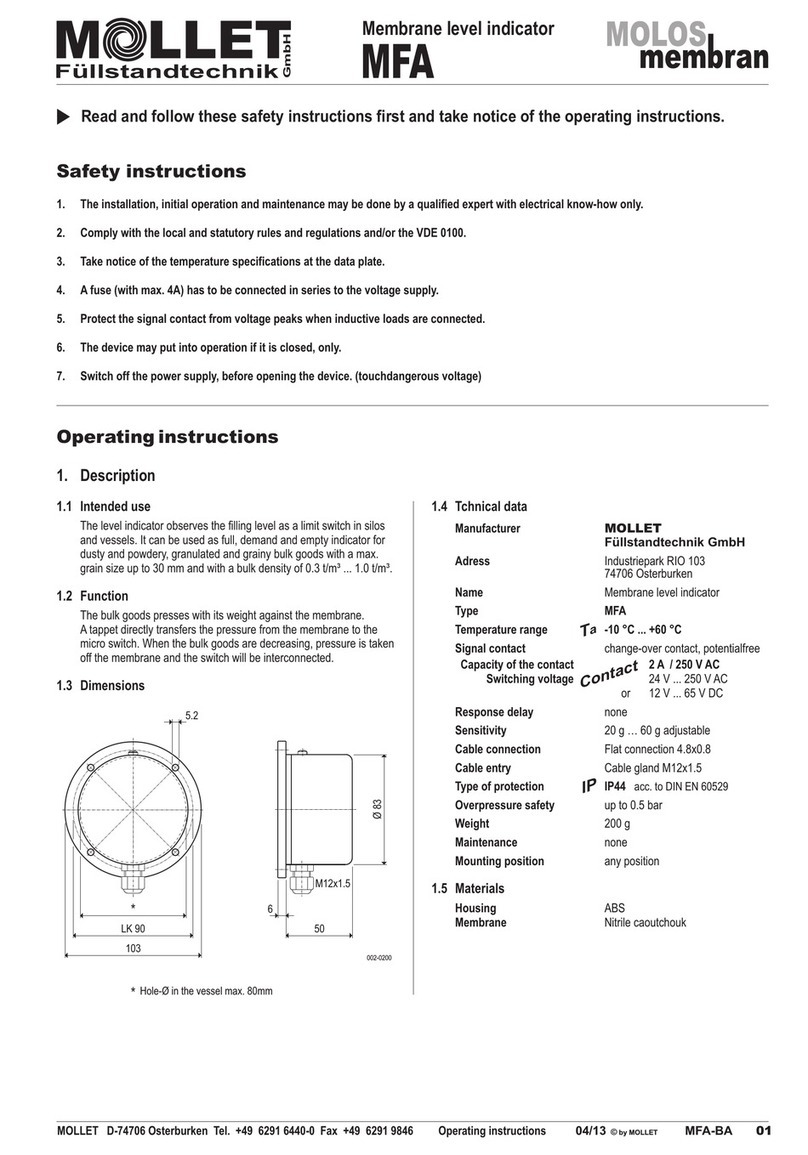

2.2 Mounting of sensor (cone) and rod

- Screw the rod with the left and rigth screwed hexagonal nuts in the

nut with no. 10 and no. 13 open jaw wrench.

and fix it with 4 washers and screws M6.

Circuit diagram

- After electrical connection, tighten the cable gland.

then the pendulum as described.

- Screw now this pendulum in the buckling protector and counter the

- Damaged devices have to put out of operation immediately.

5.1 Maintenance

- Use the level indicator in its intended application only.

- Ignoring of the safety instructions and the operating instructions.

-

- Violation against applicable law and standards.

- The level indicator needs no maintenance.

4.1 Normal operation

-

5.2 Servicing

-

4. Utilization

- Store the level indicator dry and dust-free.

- Damaged parts have immediately replaced with similar.

5. Maintenance and servicing

indicator must not be used any more.

-

- Until the complete reconstruction of the proper function, the level

- Not intended use.

4.2 Inexpert handling

6. Storage

- Dismount the pendulum and store the housing on it´s top.

- Mounting of spare parts which are no original parts.

- Comply with the specifications on the data plate.

- The level indicator can be recycled.

according to the location of the carrier and the local manufacturing

7. Disposal

conditions.

- The disposal applies to the valid environmental guidelines

3. Commissioning

- Put the level indicator into operation only, if the installation and the

electrical connection have been done correctly.

- The level indicator is presetted at sensitive.

Clockwise insensitive.

- With the adjusting nut the device can be adjustable insensitive.

003-AP00

003-0701

NC

NO

C

2

3/4

1

PE

false correct

1

23/4

adjusting nut

Pendulum level indicator

PF