2. Installation

2.1 Preparation

2.2

- The level indicator has to be mounted always with the cable entry

downwards.

2.3 Electrical connection

- Check the membrane of visual transport damage.

- Read and follow the safety instructions and the operating

instructions, before handling with the device !

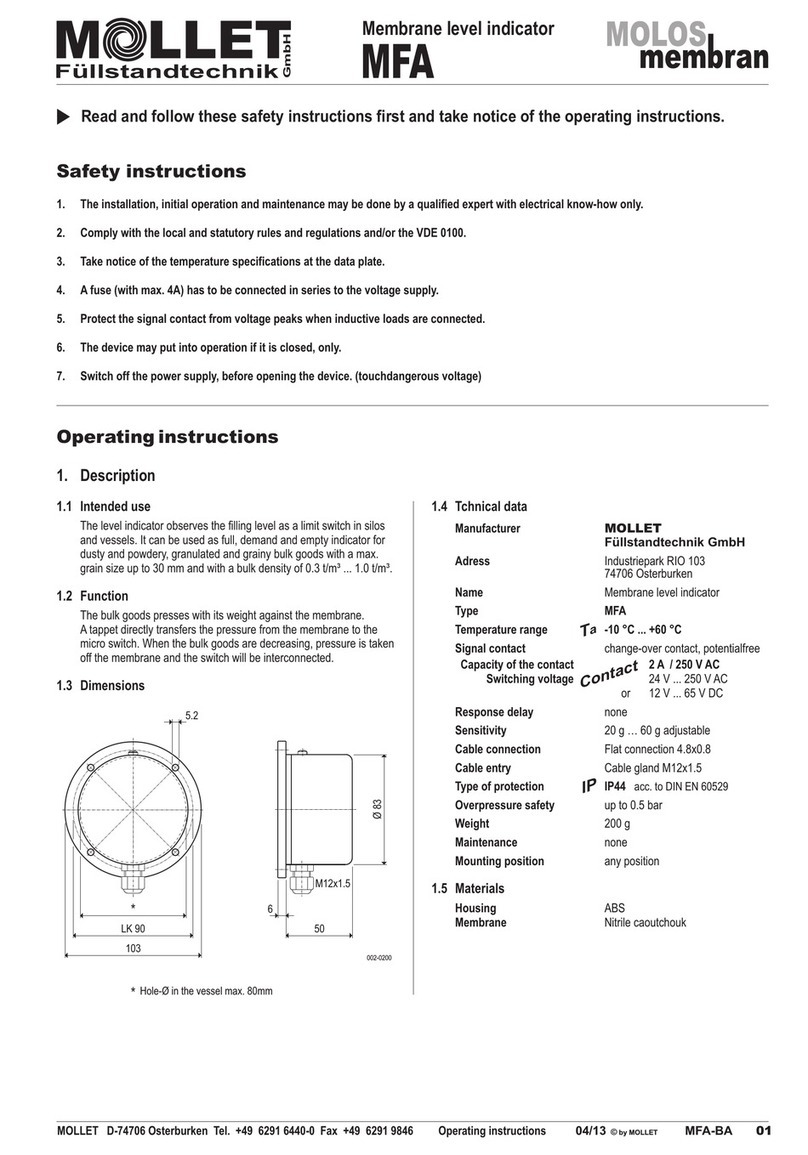

Mounting in the vessel

- Position the level indicator with the gasket at the provided flange

and fix it with 4 washers and screws M6.

Circuit diagram

2.4 Cable gland

- After electrical connection, tighten the cable gland.

- Screw the cap nut, until the cable entry is closed tightly.

-

3. Commissioning

- Put the level indicator into operation only, if the installation and the

electrical connection have been done correctly.

- The level indicator is presetted at sensitive.

- With the adjusting nut the device can be adjustable insensitive.

Clockwise insensitive.

M LLET

Füllstandtechnik

GmbH

02 MFD-BA 04/13 © by MOLLET

Operating instruction MOLLET D-74706 Osterburken Tel. +49 6291 6440-0 Fax +49 6291 9846

4. Utilization

4.1 Normal operation

- Use the level indicator in its intended application only.

- The level indicator is provided for use in silos or vessels with

pressureless operation.

- Comply with the on the data plate. Check the

membrane of the level indicator, when the permissible temperature

of bulk goods was exceeded or was fallen short off.

- Damaged devices have to put out of operation immediately.

4.2 Inexpert handling

- Ignoring of the safety instructions and the operating instructions.

- Not intended use.

- Mounting of spare parts which are no original parts.

- Violation against applicable law and standards.

-

5. Maintenance and servicing

5.1 General informations

- Do maintenance work only, if the silo or the vessel is empty and

if there is no overpressure or vacuum.

- Use original spare parts only.

5.2

- Inspect in regular intervals if there is any wear or abrasion at the

membrane. Define the control intervals, depending on the

characteristics of the bulk goods.

- In case of damage or abrasion, replace the membrane

immediately with a new membrane.

5.3 Servicing

- Damaged parts have immediately replaced with similar.

- Until the complete reconstruction of the proper function, the level

indicator must not be used any more.

-

6. Storage

- Store the level indicator dry and dust-free.

- Protect the membrane against pointed objects and ultraviolet

radiation.

-

7. Disposal

- The level indicator can be recycled.

- The disposal applies to the valid environmental guidelines

according to the location of the carrier and the local manufacturing

conditions.

-

specifications

Maintenance

002-AP02

NC NO C

P

23/4 1

1 2

3/4

adjusting nut

Membrane level indicator

MFD