4

CONTENTS

- COVER SHEET

- Declaration of Conformity

- NOTE TO THE USER

- WARRANTY

- Table of Contents

CHAPTER 1. SAFEGUARDS

1-1 Important Notices .......................................................................................... 5

1-2 Qualified Personnel ........................................................................................ 7

1-3 Danger Notices ............................................................................................. 7

1-4 Principle safety objective ............................................................................... 8

1-5 Safety notices .............................................................................................. 9

1-6 Essential Safety Checks (ESC's) ..................................................................... 13

1-8 Illumination .................................................................................................. 15

1-9 Level of sound pressure ................................................................................ 15

1-10 Training ...................................................................................................... 15

CHAPTER 2. OVERVIEW OF MACHINE

2-1 Specification ................................................................................................ 16

2-3 Flowchart for operation ................................................................................. 17

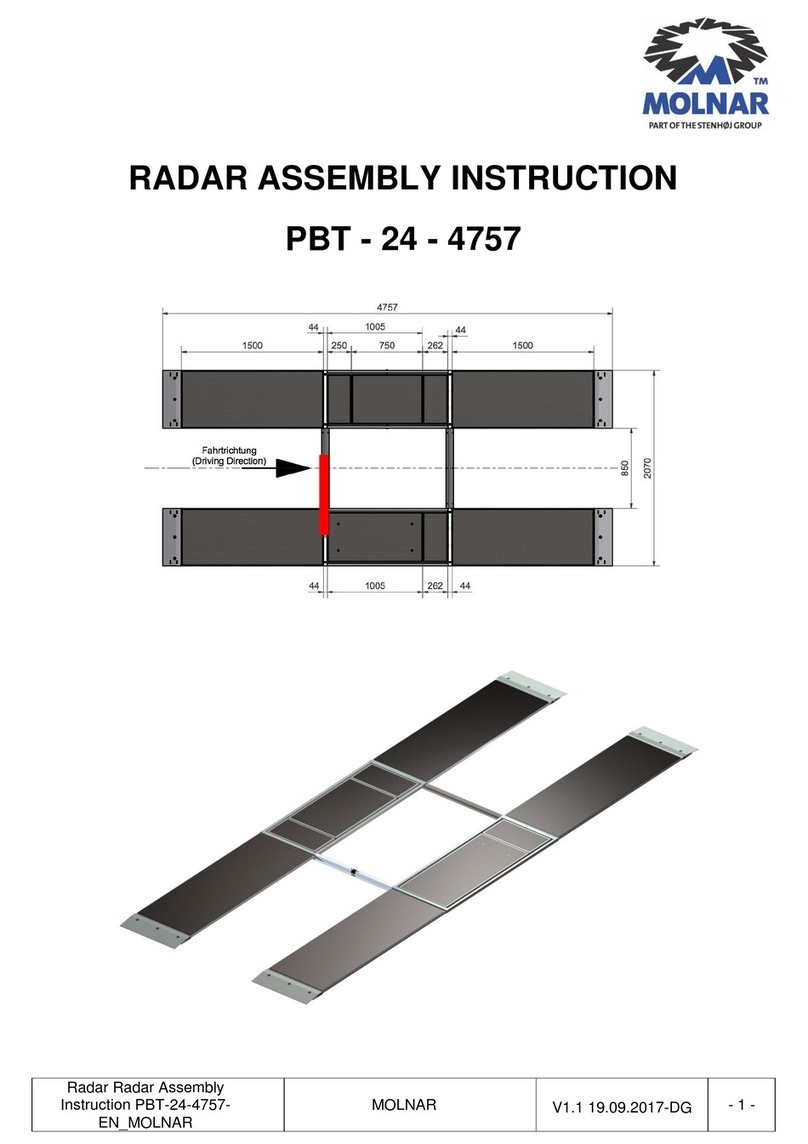

2-4 Safety device ............................................................................................... 18

CHAPTER 3. OPERATION

3-1 Warning for use ............................................................................................ 19

3-2 Checking point before operation .................................................................... 19

3-3 Preparation before operation.......................................................................... 20

3-4 Description of control panel ........................................................................... 21

3-5 Operation .................................................................................................... 22

3-6 How to lower manually the lift during emergency .............................................. 25

CHAPTER 4. TROUBLESHOOTING

4-1 Inspection and repair .................................................................................... 27

4-2 How to adjust the Inner Width of the Lift Platform ............................................. 28

4-3 How to check and replace the Wire Rop .......................................................... 29

4-4 How to adjust the upper limit position. ............................................................ 29

CHAPTER 5. MAINTENANCE

5-1 General caution during maintenance ............................................................... 30

5-2 Check List and periodic maintenance .............................................................. 31

5-3 Lubricant ..................................................................................................... 31

APPENDIX

1. Electric Circuit …………………………………………………………………………………………32

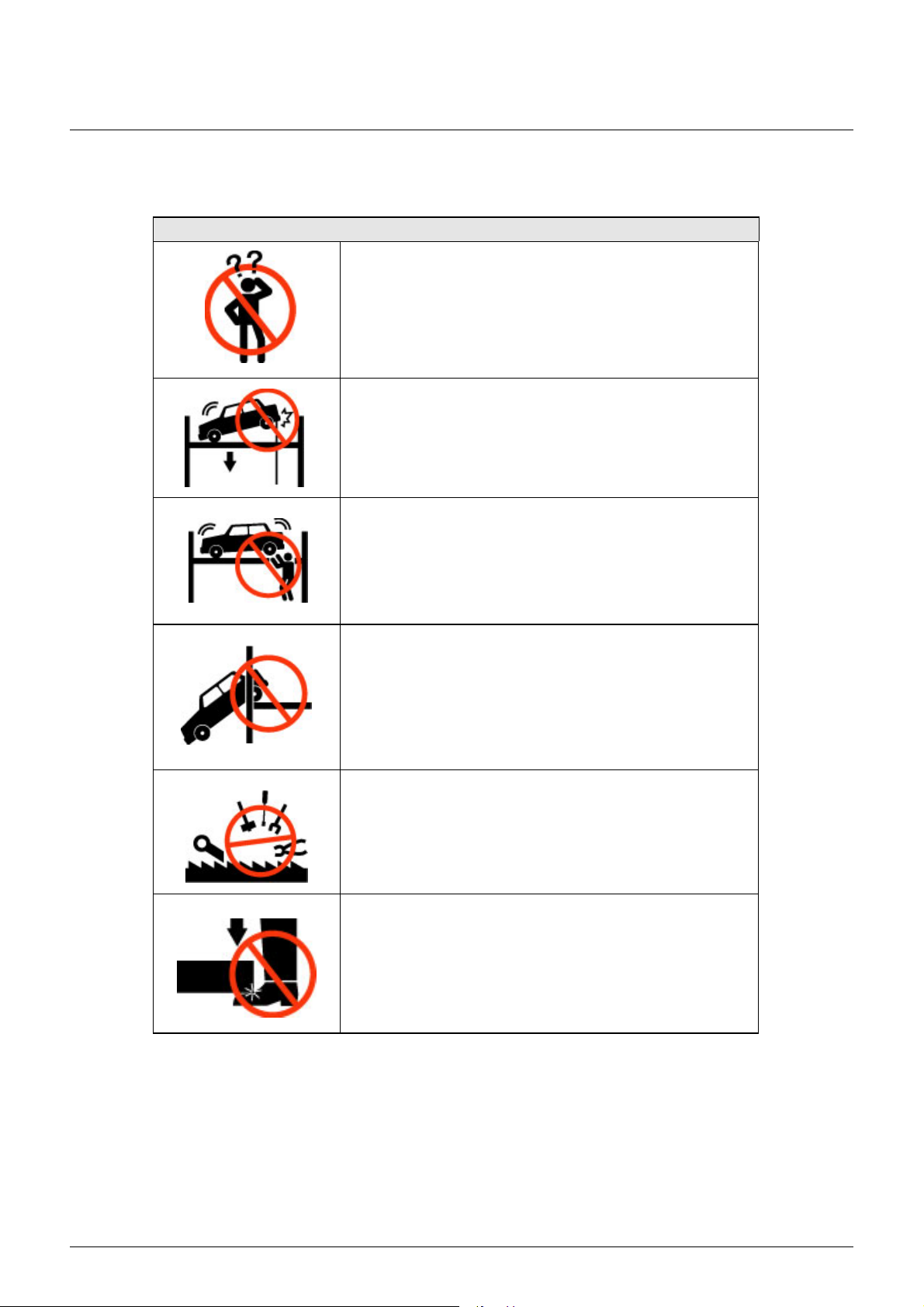

1-7 Safety Signs .................................................................................................. 14

2.Hydraulic Circuit ………………………………………………………………………………….……33