Molnar Hoists All Rounder Installation 7

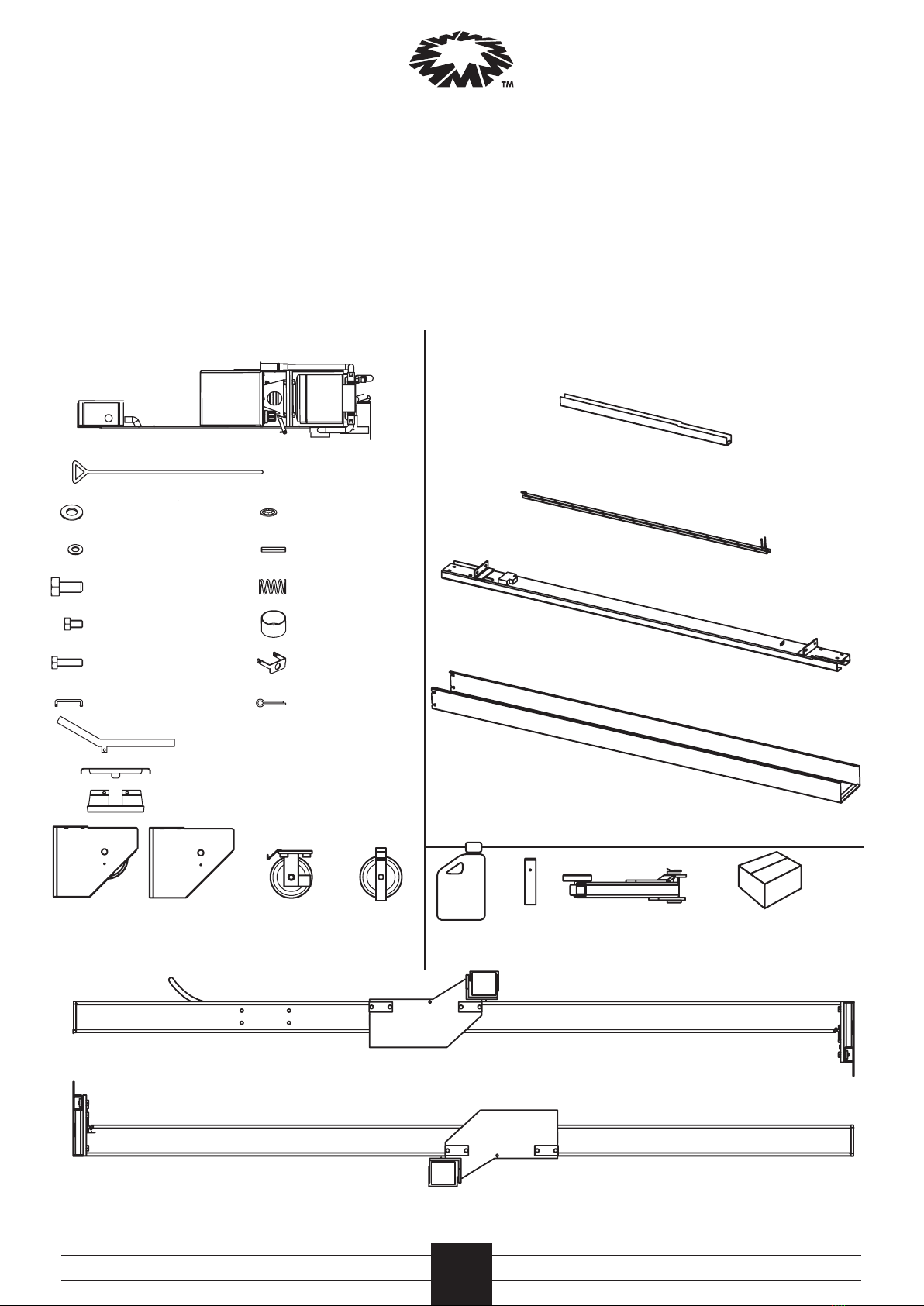

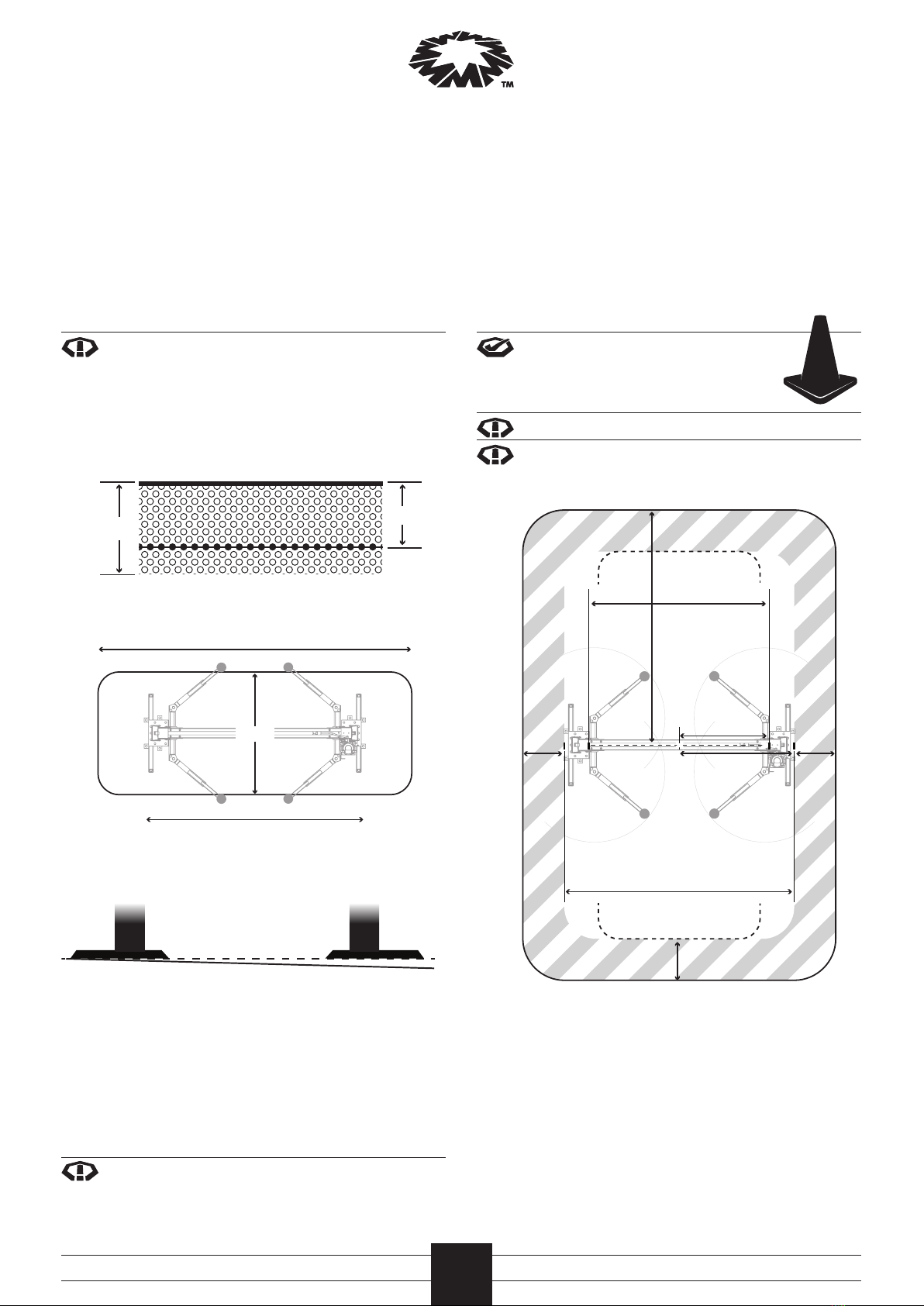

2 Unpack and position

1 Using a pallet jack, position hoist in front of the marked

line.

2 Cut bindings and remove the plastic cover. Cut the steel

strapping around the two timber crates. Open crate lids

with pry bar and lay out contents on the floor, clear of the

working area. Discard crates and packing material.

Plastic cover can be used to collect packaging refuse

3 Carefully check contents against the packing list on

the previous page. If any contents are missing, stop

installation and immediately contact your distributor.

4 Remove strapping holding the lifting arms to the hoist.

Discard strapping and set lifting arms aside.

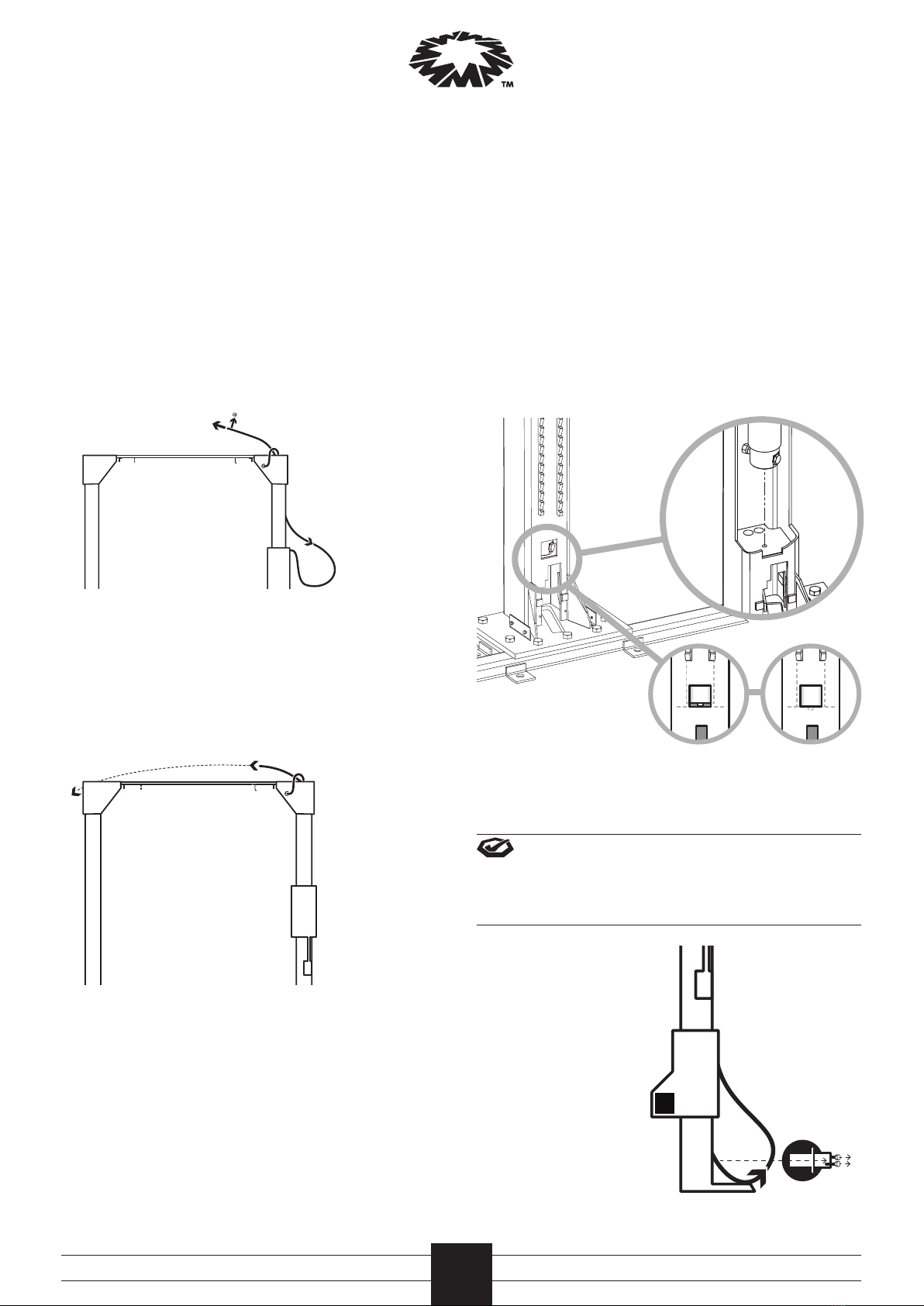

5 Locate the control-post (identified by the conduit).

Position hoist so that the base of the control-post is

positioned on the preferred side for motor operation.

6 Once correctly positioned, lower the pallet jack until the

packing legs are touching the ground but the post are

still supported by the pallet jack.

7 First cut away the strapping from around the carriage

and then cut away the remaining strapping from around

the hoist.

Do not cut strapping on the control post marked

with red and white sticker, this strapping must

remain until posts are upright.

8 Lower hoist and carefully remove pallet jack

9 Using the pallet jack or pry bar, carefully separate the

posts to create about a 200mm gap between them.

3 Pre assemble

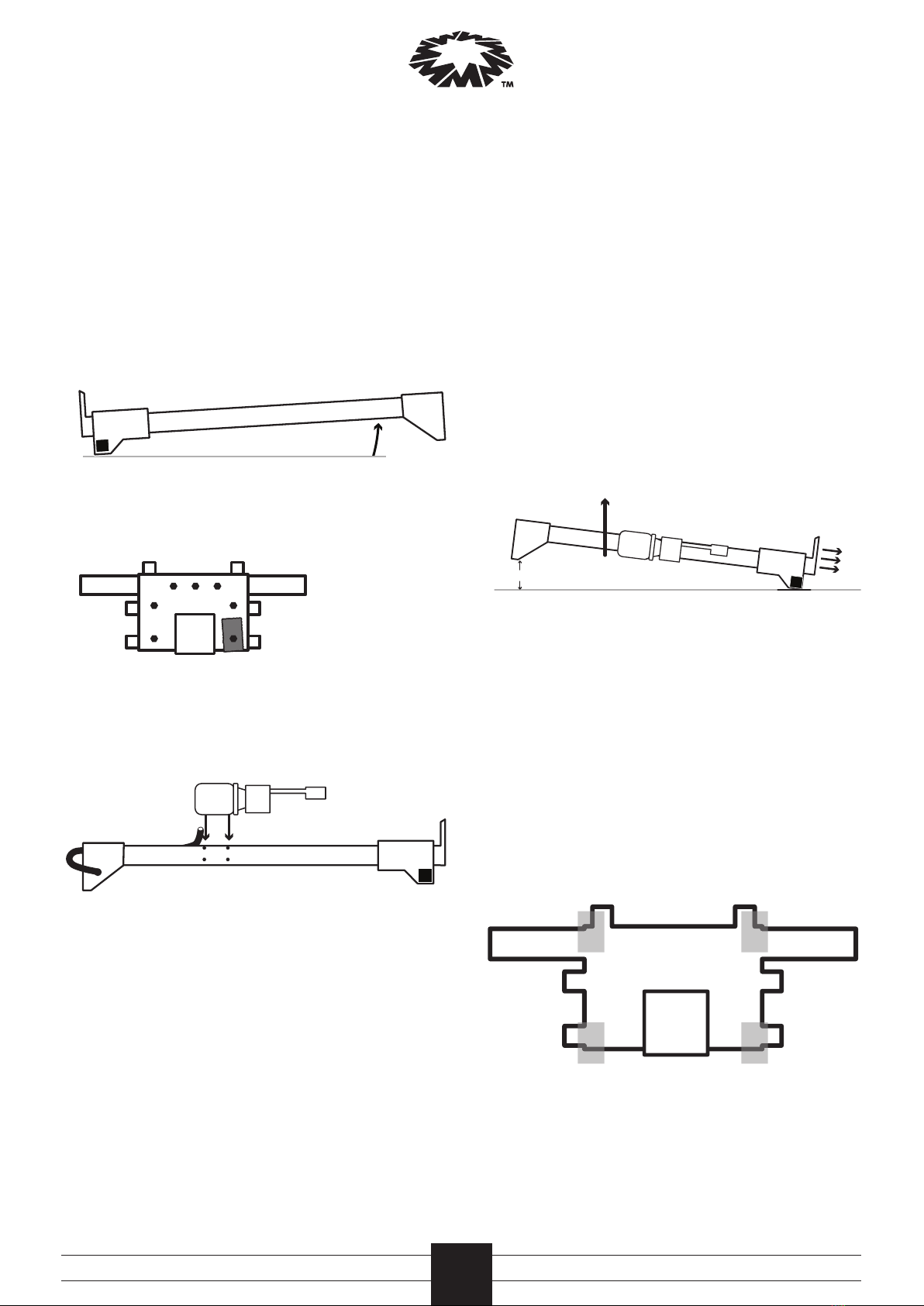

1 Working first on the non-control post, use the pallet jack

to lift it up to remove the load on the packing leg. Using

an Air Wrench, undo the 2xM16 bolts and nuts holding

the packing leg to the base frame. Remove the packing

leg and refit the M16 nuts and bolts to it ready for return.

2 Repeat this process for the control post

Packing legs must be returned to distributor

or place of purchase for full refund of deposit

3 Working on the control-post, place the pallet jack under

the top end, raise slightly and swing the top clear of the

other post.

4 Pull the conduit through the top of the control-post,

twisting as you pull, until approximately 150mm is left

protruding from the side of the post.

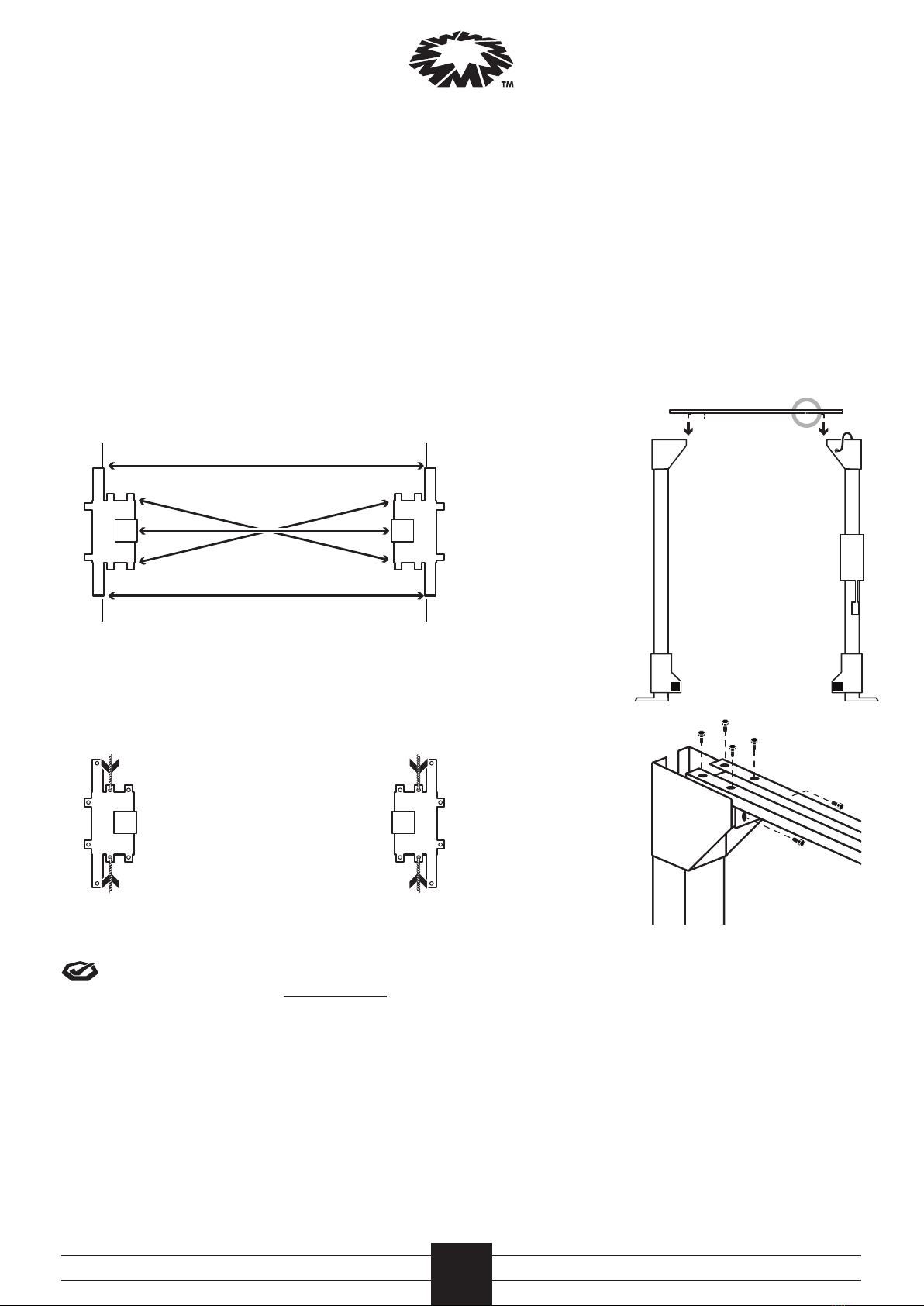

5 Locate the control-post cap: a. unscrew the M6 bolt

holding the pulley in the control-post cap. b. Support the

pulley while removing the pin. c. Remove the pulley and

set to one side, ensuring both pulley spacers have also

been removed.

6 Fit control-post cap to control-post: feed the conduit

through the top of the control-post cap while sliding

the cap onto the control-post. Tuck the conduit into the

pulley hole to secure during installation.

7 Lower to ground and remove the pallet jack.

d

e

s

i

r

e

d

l

o

c

a

t

i

o

n

o

f

c

o

n

t

r

o

l

-

p

o

s

t

control-post

intended location of hoist

base

150

Installation

6a. unscrew bolt 6b. remove pin

6c. remove pulley

Installation