1

Contents

INTRODUCTION .......................................................................................................................................... 2

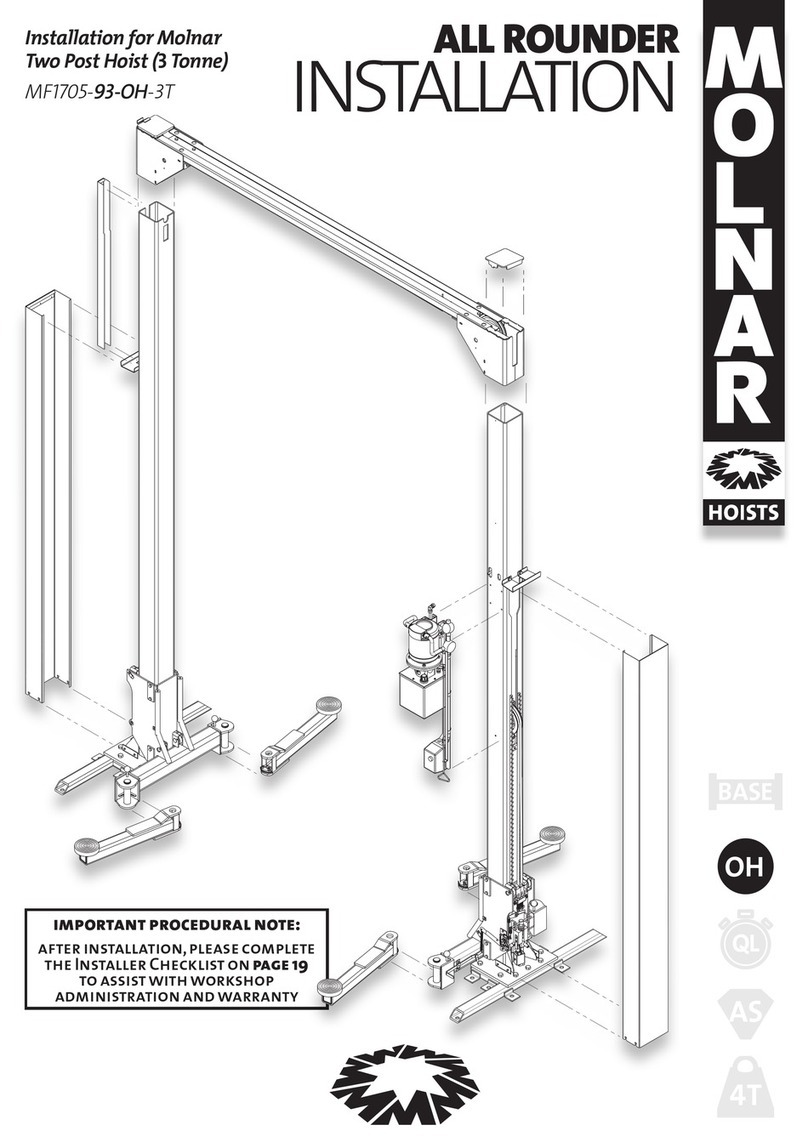

OVERVIEW .................................................................................................................................................. 3

SAFETY ....................................................................................................................................................... 4

TOOL LIST ................................................................................................................................................... 4

MATERIALS LIST ......................................................................................................................................... 5

SAFETY PRECAUTIONS ............................................................................................................................. 6

MAINTENANCE ........................................................................................................................................... 7

TECHNICIAN MAINTENANCE SCHEDULE ................................................................................................. 8

ELECTRICAL CHECK .................................................................................................................................. 9

INSTALLATION CHECK ............................................................................................................................... 9

COVER REMOVAL ...................................................................................................................................... 9

Release Cable Cover Removal ................................................................................................................. 9

Cylinder Cover Removal ........................................................................................................................... 9

CYLINDER REPLACEMENT ...................................................................................................................... 10

Cylinder Removal .................................................................................................................................... 10

Cylinder Fitting ........................................................................................................................................ 12

Bleeding Hydraulic System ..................................................................................................................... 13

BALANCE CABLE INSPECTION ............................................................................................................... 14

Balance Cable Replacement Criteria ...................................................................................................... 14

Balance Cable & Pulley Inspection Procedure ........................................................................................ 14

BALANCE CABLE ADJUSTMENT ............................................................................................................. 16

Balance Cable Adjustment Check ........................................................................................................... 16

Balance Cable Adjustment Procedure ..................................................................................................... 17

Lock Release Cable Adjustment Procedure ............................................................................................ 18

BALANCE CABLE & PULLEY REPLACEMENT ......................................................................................... 20

Balance Cable & Bottom Pulley Removal ................................................................................................ 20

New Balance Cable and Bottom Pulley Replacement ............................................................................. 20

TOP BALANCE CABLE PULLEY ............................................................................................................... 21

Top Balance Cable Pulley Replacement ................................................................................................. 21

CARRIAGE SLIDE BLOCKS ...................................................................................................................... 22

Carriage Slide Block Tracks Inspection and Lubrication .......................................................................... 22

Carriage Slide Block Replacement .......................................................................................................... 22

HYDRAULIC SYSTEM CHECK .................................................................................................................. 24