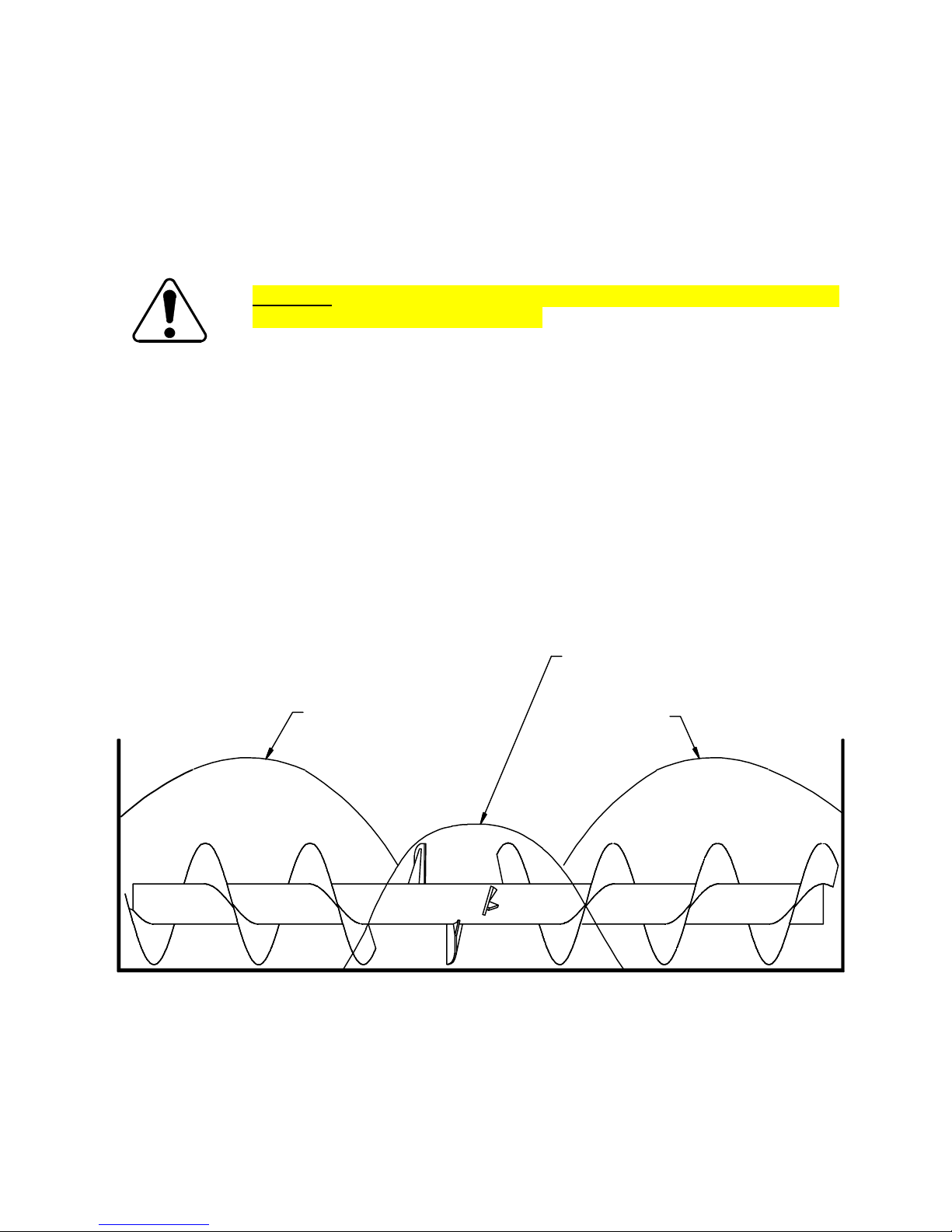

3. It is very important that before using your MONOMIXER, proper PTO length be determined

and maintained. The PTO must have a minimum and maximum engagement length that falls

within the safe use of a PTO. Too short of a PTO could result in the two halves coming apart

under load or going over uneven terrain; too long of a PTO can result in serious damage to

either end of the drive train. It is recommended that a minimum of 5" of engagement be

maintained on the PTO. Your MONOMIXER has been supplied to you with a standard length

PTO that will work with all tractors provided drawbar adjustments are made to maintain the

correct PTO length.

DANGER!TO PREVENT SERIOUS INJURY OR DEATH, TURN

OFF PTO, TURN OFF TRACTOR AND PULL THE KEY, SET PARKING

BRAKE AND WAIT FOR ALL MOTION TO STOP BEFORE ADJUSTING

PTO LENGTH AND WORKING ON THE DRAWBAR.

4. The swing arm is designed to move feed on the straight side of the mixer to achieve thorough

and completely mixed ration. The swing arm has an adjustable flow control, which can

increase or decrease speed. The swing arm has a factory preset of 15 RPM and it is

recommended that no more than 20 RPM maximum be exceeded. The swing arm also is

designed to stall when over loaded. If the arm does stand still, it is only because there is too

much feed in the way of the arm. When the feed has moved, the arm will automatically start

again.

CAUTION!DO NOT EXCEED THE MAXIMUM RPM OF THE

SWING ARM AS SERIOUS STRUCTURAL DAMAGE TO THE SIDE

OF THE MONOMIXER COULD RESULT!

5. The MONOMIXER will effectively mix all ingredients in a Total Mixed Ration including small

grains, corn, concentrates and premixes, cotton, seed, corn and hay silage etc. The

MONOMIXER is also capable of processing dry, long stem hay into your ration. It is not

recommended that wrapped and ensiled round bales be processed in the MONOMIXER.

IMPORTANT! THE MIXER SHOULD ALWAYS STAND LEVEL WHEN MIXING!

6. Due to the nature of mixing and cutting long stem hay, pin shearing is something that can be

expected. The shear pin is designed to be the weakest link in the drive train, and its shearing is

to prevent damage to critical components. Therefore never replace shear pins with a higher

tensile strength or grade pin. If a machine is regularly shearing pins, the operator should first

look for mechanical problems such as worn knives or a bearing failure, then evaluate loading

procedures and lastly, call for technical assistance.