FG063 roll slicer RevB18 05-10-18

oThe MONO roll slicer should be placed on a level, stable surface.

oThe blade should be cleaned ready for use by passing some stale rolls through the

machine.

Single phase electrical connection.

Insert plug into a socket nearby so that the cable is not trailing across the floor.

Use as the instructions in section 8.0

Three phase electrical connection

The electrical connection should be made by an authorised electrician.

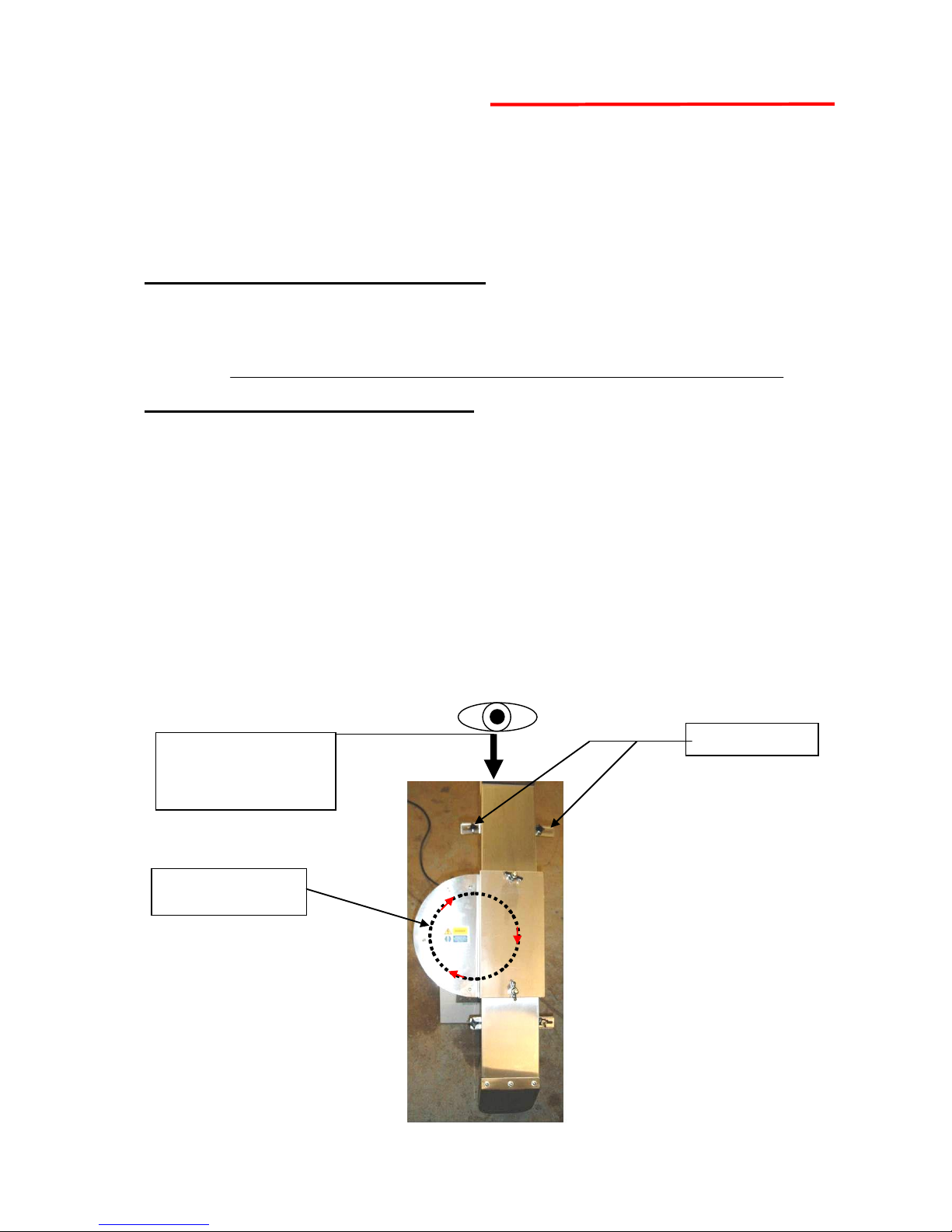

The blade rotation direction must be checked as follows:

oAfter connecting the power supply move the top guides as far apart as possible

(see section 9.0) so that the blade can be seen when looking down the chute.

oPress green button and then the red button, so that the motor is powered very briefly.

oLook down the chute and note which way the blade is rotating as it stops.

(DO NOT RUN FOR MORE THAN A BRIEF PERIOD because if the rotation is wrong

the blade could come loose)

If the blade rotation in not correct, change round any two of the three phase carrying

wires.