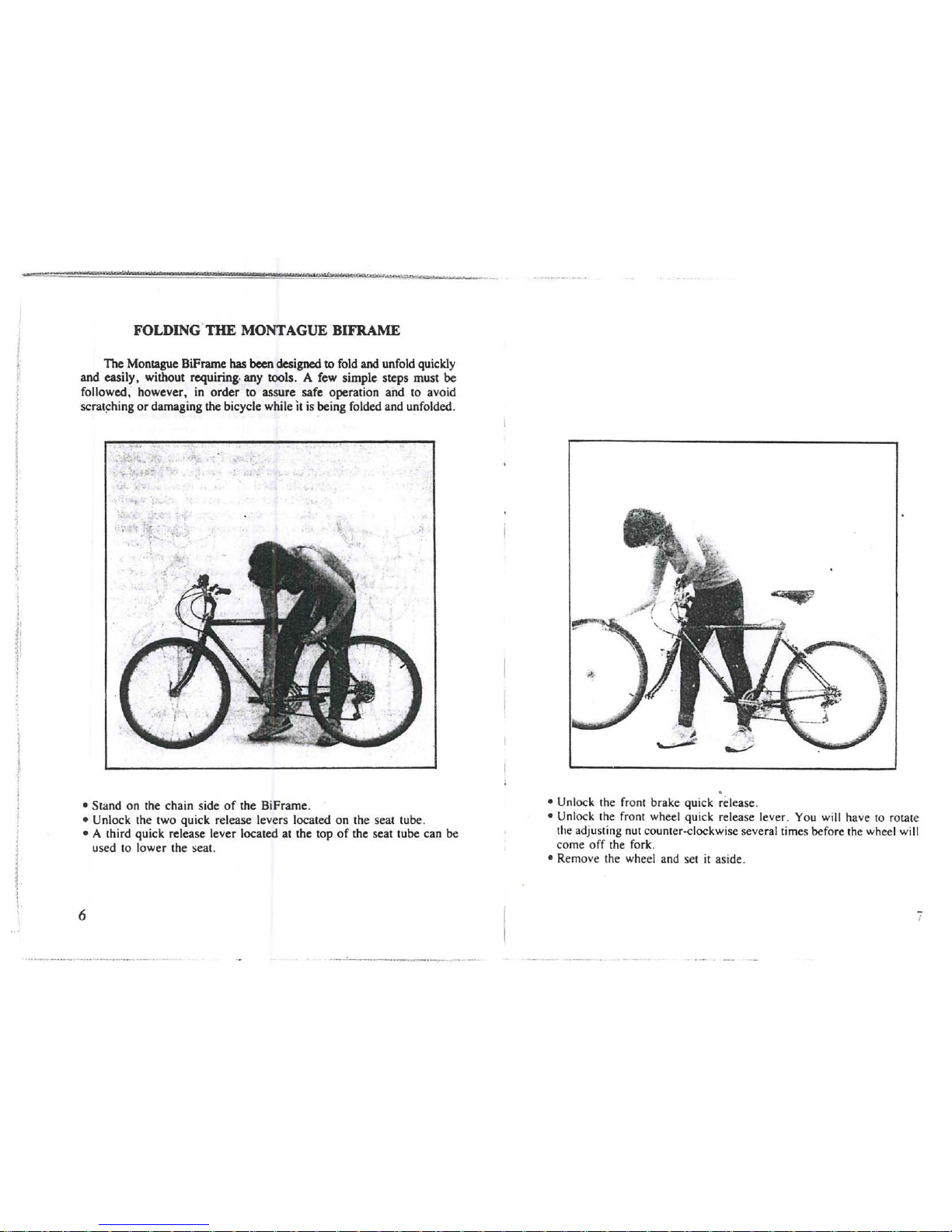

UNFOLDING

THE

MONTAGUE

BIFRAME

•

To

unfold the

BiFrame,

first loosen the seat

tube

quick release levers.

•Rotate the pedals so that the pedal

on

the chain side

of

the BiFrame

is

at the bottom

of

its swing pointed away from the seat.

•

Grabbing

the handlebar stem with

your

right hand, and the back wheel

with

your

left hand, pull open the BiFrame, until the safety latch snaps

into place.

•Tighten the two seat tutie quick release levers.

•Put the front wheel back

on

the bicycle, tightening the front wheel quick

release lever

(see

instructions

on

page

19).

•Tighten the front brake quick release

•Raise

the

seat as necessary.

•While the

BiFrame

is equipped with

an

automatic safety latch for

your

protection. this safety latch is designed to

be

used only in conjunction

with the quick release mechanisms.

Make sure the safety latch

is

in the locked position shown

in

Fig. 5a before riding the bicycle.

NOTE:

The

BiFrame can sometimes get caught in the folded position.

This can happen when the bicycle is not folded flat enough which causes

the pedal and

crank

arm

to hit the

down

tube when rotated.

If

this

happens, manually turn

the

rear

wheel in the direction it would spin

if

the bicycle were being ridden. At the same time, turn the pedal and crank

arm

in

the same direction until they

are

in the

proper

position for

unfolding.

CAUTION:

It

is

very important to lock all five quick releases securely

before riding:

(I)

the front wheel quick relea'se lever. (2) the front brake

quick release, (3) the seat

quitk

release lever and (4 &5) the top and

bottom seat tube quick release levers.

If

you

do

not understand how to fold and unfold the BiFrame. be

sure to ask

your

dealer

for assistance.

I

:2

SAFETY ON

THE

ROAD

Wear ahelmet

that

meets Ansi

Z290.4

requirements.

Observe all traffic regulations. Obey red and green lights, one·way

streets, stop signs, etc.

Ride with

the

traffic, not against

It.

Ride single file

in

astraight

line.

Have satisfactory signaling device to warn

of

approach.

Give pedestrians the right

of

way.

Slow down at all street intersections and look

to

the right and left

before crossing.

Always use proper hand signals for turning and stopping.

Watch for cars pulling

out

into traffic and for sudden opening

of

car doors.

Avoid potholes, drainage grates or other road

su~face

hazards.

Cross railroad tracks at aright angle.

Never hitch on

other

vehicles, do

not

"Stunt"

ride or race in'

traffic.

Don't

weave

in

and

out

of

traffic or swerve from side to side.

Never carry

other

riders or packages that obstruct vision or proper

control

of

the bicycle.

Before riding, check your brakes.

Be

sure they are operating

efficiently and that your bicycle

-is

in

perfect running condition.

CAUTION

IN

WET

WEATHER

RIDING

No brakes work as well under wet conditions as.they do under dry

conditions.

In

rainy

or

wet weather. special precautions must

be

taken

to insure safety

in

stopping. Proper adjustment and cable lubrication will

help, but the major precaution

res~

with you. Increased lever forces are

required on wet

or

rainy weather arid care must be exercised

to

maintain

safety under these conditions. Ride slower than normal and apply your

brakes sooner than normal conditions would require.

-~

.......

;;:'"

.;~

...

~~~

..

-"

......

'

..

-.""

.-.'~'

.

--"

,.

....

---

~_.

~..._

..

-.

-_.-

13