8

All fixed (non-mobile) appliances MUST be fitted

with a manual gas cook upstream of the appli-

ance to provide a means of isolation for servicing

and cleaning. A union or similar means of discon-

nection must be provided between the gas cook

and the appliance.

A manually operable valve must be fitted to the

gas supply to the kitchen to enable it to be isolat-

ed in an emergency. Wherever practical, this shall

be located either outside the kitchen or near an

exit in a readily accessible position.

Where it is not practical to do this, an automatic

isolation valve system shall be fitted which can be

operated from a readily accessible position near

the exit.

At locations where the manual isolation valve is

fitted or the automatic system can be reset, a

notice MUST be fitted, stating:

―ALL DOWNSTREAM BURNER AND PILOT

VALVES MUST BE TURNED OFF PRIOR TO

ATTEMPTING TO RESTORE THE SUPPLY.

AFTER EXTENDED SHUT OFF, PURGE

BEFORE RESTORING GAS.‖

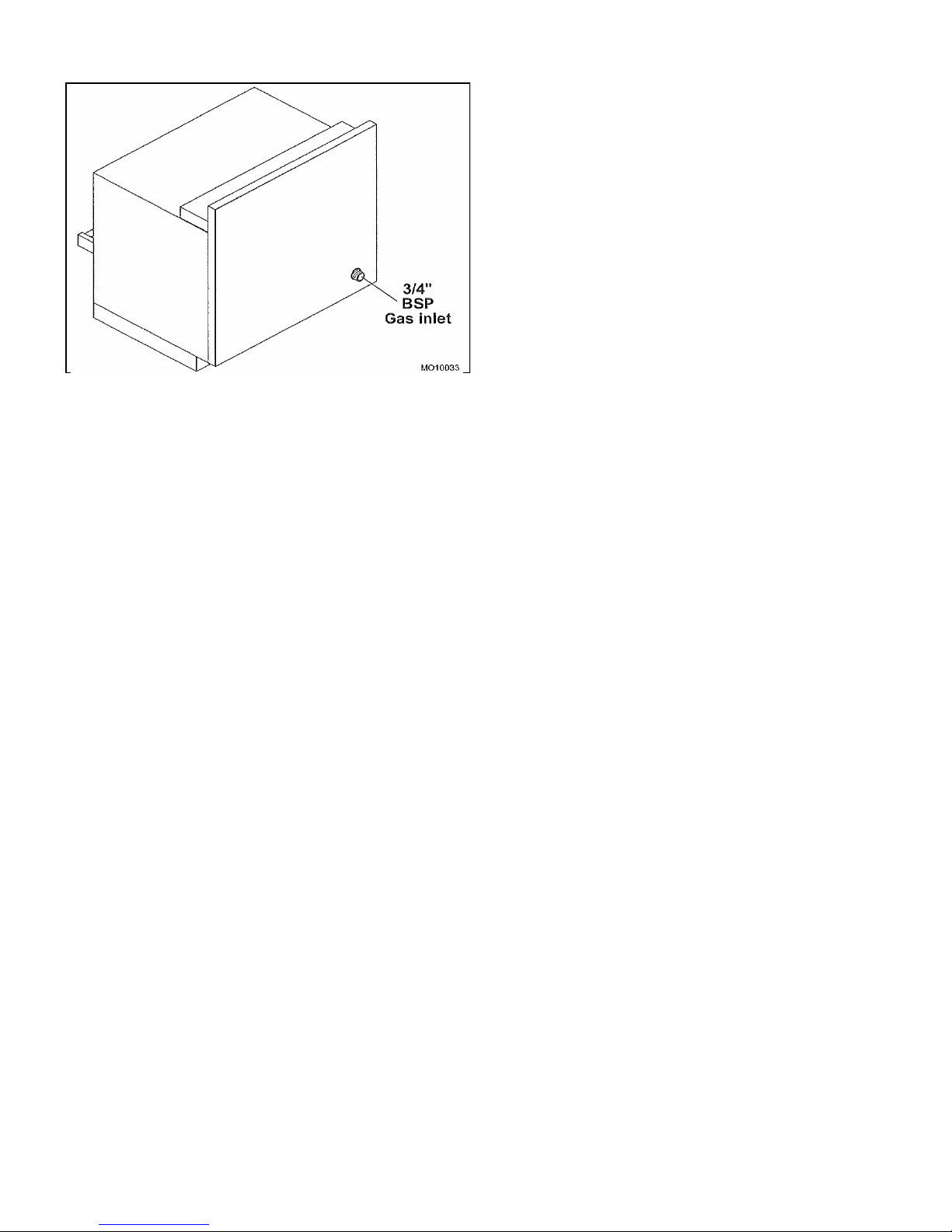

GAS CONNECTION

Before connecting the broiler(s) to the gas supply

line, be sure that all new piping has been cleaned

and purged to prevent any foreign matter from

being carried into the controls by the gas. In some

cases, filters or drops are recommended. A

separate gas shutoff valve must be installed

upstream from the gas pressure regulator

adjacent to the broiler and located in an accessi-

ble area.

It is important that adequately sized piping be run

directly to the point of connection at the broiler

with as few elbows and tees as possible. Consult

your local gas company for proper piping size and

gas pressure. Each broiler has a 3/4" NPT

manifold input located at the lower left rear of the

broiler, Figure 4. On dual broilers, each broiler

must have a separate regulator.

NOTE: Pipe joint compound or thread sealant

that is used should be resistant to action of

liquefied petroleum gases.

Floor Mounted Ranges

1. Place the first unit in the exact position it will

occupy in the battery.

2. Using a carpenter’s level, level the unit front-

to-rear and side-to-side. AN UNLEVELED UNIT

WILL ADVERSELY AFFECT PERFORMANCE.

Adjust as follows:

FLOOR INSTALLATION ON LEGS: Level by

turning foot on leg.

CURB INSTALLATION: Place shim under the low

side. This operation is important since variations

in floors and curbs are common. Unless units are

level, aligning the gas supply manifold will be

difficult and the units will not fit together tightly.

3. Remove the valve panel from the broiler.

4. Move the next unit into position.

5. Engage union nut on manifold with male fitting

on next unit and draw up union nut hand tight. Be

sure appliances meet together both front and rear.

If manifolds do not align, then units are not level.

In extreme cases, it may be necessary to loosen

manifold bolts and adjust.

6. Continue leveling and connecting gas supply

manifolds together until all appliances in battery

are connected.

7. Tighten manifold gas union. Use backup

wrench to prevent manifold from rotating.

FAILURE TO DO THIS MAY RESULT IN

DAMAGE TO THE PILOTS AND GAS VALVES.

GAS SUPPLY

The local gas region should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas and to

ensure that the meter is adequate for the required

flow rate. The pipe work from the meter to the

appliances must be of appropriate size. Where a

number of appliances are installed in a battery, no

more than five should be served by any one

supply pipe.