3.HYDRAULIC SYSTEM PREPARATION

To prolong servovalve operational life and to reduce hydraulic system

maintenance, it is recommended that the hydraulic fluid be kept at a cleanliness

level of ISO DIS 4406 code 16/13 maximum,14/11 recommended.The most

effective filtration scheme uses a kidney loop or “off-line” filtration.The filter for

the“off-line” filtration should be a ß3≥75 filter for maximum effectiveness.

Upon system startup,and prior to mounting the servovalve,the entire

hydraulic system should be purged of built-in contaminating particles by an

adequate flushing.The servovalve should be replaced by a flushing manifold and

the hydraulic circuit powered up under conditions of fluid temperature and fluid

velocity reasonably simulating normal operating conditions.New system filters

are installed during the flushing process whenever the pressure drop across the

filter element becomes excessive.The flushing processes should turn over the

fluid in the reservoir between fifty to one hundred times.

To maintain a clean hydraulic system,the filters must be replaced on a

periodic basis. It is best to monitor the pressure drop across the filter assembly

and replace the filter element when the pressure drop becomes excessive. In

addition to other filters that are installed in the hydraulic circuit,it is

recommended that a large capacity,low pressure ß3≥75 filter be installed in the

return line. This filter will increase the interval between filter element

replacements and greatly reduce the system contamination level.

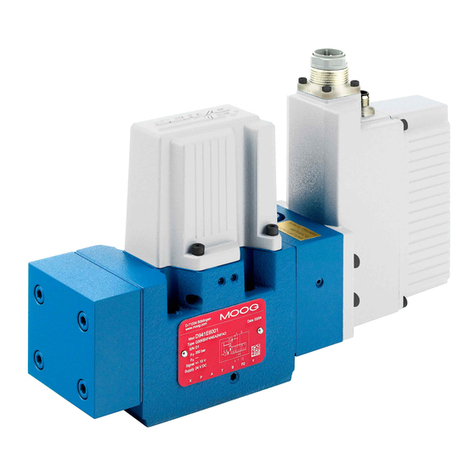

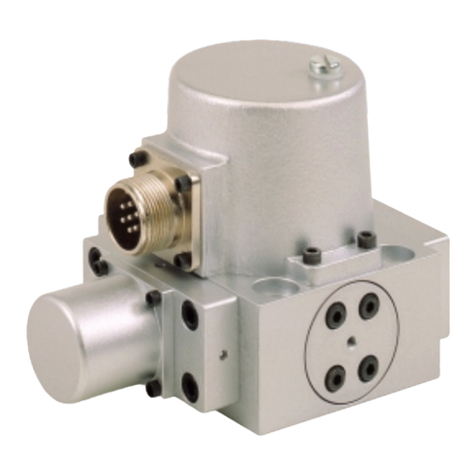

4.INSTALLATION

The Moog 631 Series Servovalves may be mounted in any position,provided the

servovalve pressure,control,and return ports match respective manifold ports.

The mounting pattern and port location of servovalve are shown on Figure 4.

Apply a light film of oil to the mounting screw threads and torque the screws to

96 inch-pounds.

Wiring mating connector for desired coil configuration and polarity.

Thread connector to valve.

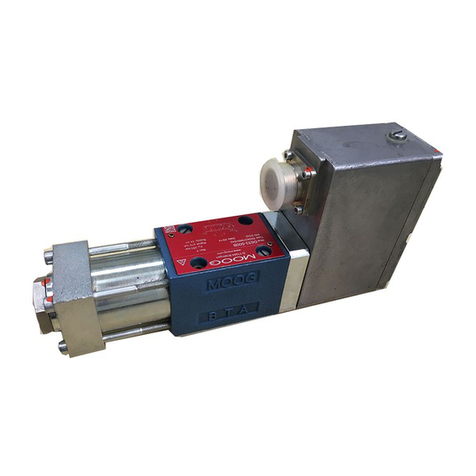

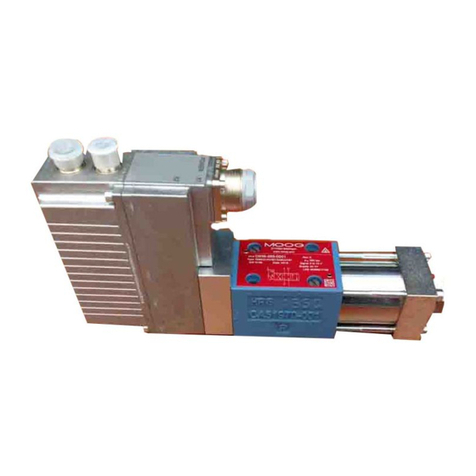

5.MECHANICAL NULLADJUSTMENT

It may be desirable to adjust the servovalve for flow null independent of other

system parameters. The mechanical null adjustment permits convenient control

function set-ups.

The mechanical null adjustor is a hex socket setscrew located behind the

pan head screw in the motor cap (see Figure 2) which,when adjusted,provides

control of the spool position to obtain the desired flow null.

NORMALADJUSTMENT SHOULD REQUIRE LESSTHAN ± ONETURN.

LIMIT NULL SCREWADJUSTMENTTO LESSTHAN ±TWOTURNS.

Adjustment Procedure

a. Using a blade screwdriver,remove the null access screw to permit

adjustment of the hex socket setscrew.

b. Using a 2-1/2inch long,1/8inchAllenWrench,adjust the set screw to obtain

the desired flow null.

Note: Clockwise rotation of the set screw produces flow out portA.

c. After the desired flow null has been obtained, replace the null access screw.

Tools and Equipment

a. Blade screwdriver

b. Allen wrench set (3mm,1/8inch)

c. Tweezers

6.GENERAL SERVICING RECOMMENDATIONS

a. Disconnect the electrical lead to the servovalve.

b. Relieve the hydraulic system of residual pressure.

c. Remove the servovalve.

Table 1.Replacement Parts

Part Description Qty. Part Number

631 Series Filter Replacement Kit 1 B52555RK69K1

Base O-Ring 5 G2141-12-20

Base O-Ring 1 G2141-8-20

Filter O-Ring (1) 1 G2141-13-15

Filter O-Ring (1) 1 G2141-17-20

Filter (1) 1 G2916-100

(1) Included in Filter Replacement Kit

Figure 2

Mechanical NullAdjustment NullAccess Screw