5. HYDRAULIC SYSTEM PREPARATION

To prolong servovalve operational life and to reduce hydraulic system

maintenance, it is recommended that the hydraulic fluid be kept at a

cleanliness level of ISO DIS 4406 Code 16/13 maximum, 14/11 recommended.

The most effective filtration scheme incorporates the use of a kidney loop

or “off-line” filtration as one of the major filtration components. The filter

for the “off-line” filtration scheme should be a B3≥75 filter for maximum

effectiveness.

Upon system startup, and prior to mounting the servovalve, the entire

hydraulic system should be purged of built-in contaminating particles by an

adequate flushing. The servovalve should be replaced by a flushing manifold

and the hydraulic circuit powered up under conditions of fluid temperature

and fluid velocity reasonably simulating normal operating conditions. New

system filters are installed during the flushing process whenever the pressure

drop across the filter element becomes excessive. The flushing processes

should turn over the fluid in the reservoir between fifty to one hundred

times.

To maintain a clean hydraulic system, the filters must be replaced on

a periodic basis. It is best to monitor the pressure drop across the filter

assembly and replace the filter element when the pressure drop becomes

excessive. In addition to other filters that are installed in the hydraulic

circuit, it is recommended that a large capacity, low pressure ß3≥75 filter be

installed in the return line. This filter will increase the interval between filter

element replacement and greatly reduce the system contamination level.

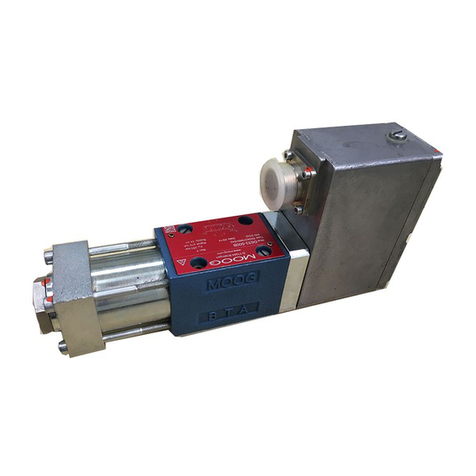

6. INSTALLATION

The Moog .760K Series Industrial Servovalve may be mounted in any

position, provided the servovalve pressure, control, and tank ports match

respective manifold ports. The mounting pattern and port location of the

servovalve is shown on figure 4. The servovalve should be mounted with

5/16-18 x 1.75 inch long, socket head cap screws. Apply a light film of oil to

the screw threads and torque to 96 inch pounds. Wire mating connector for

desired coil configuration and polarity. Thread connector to valve.

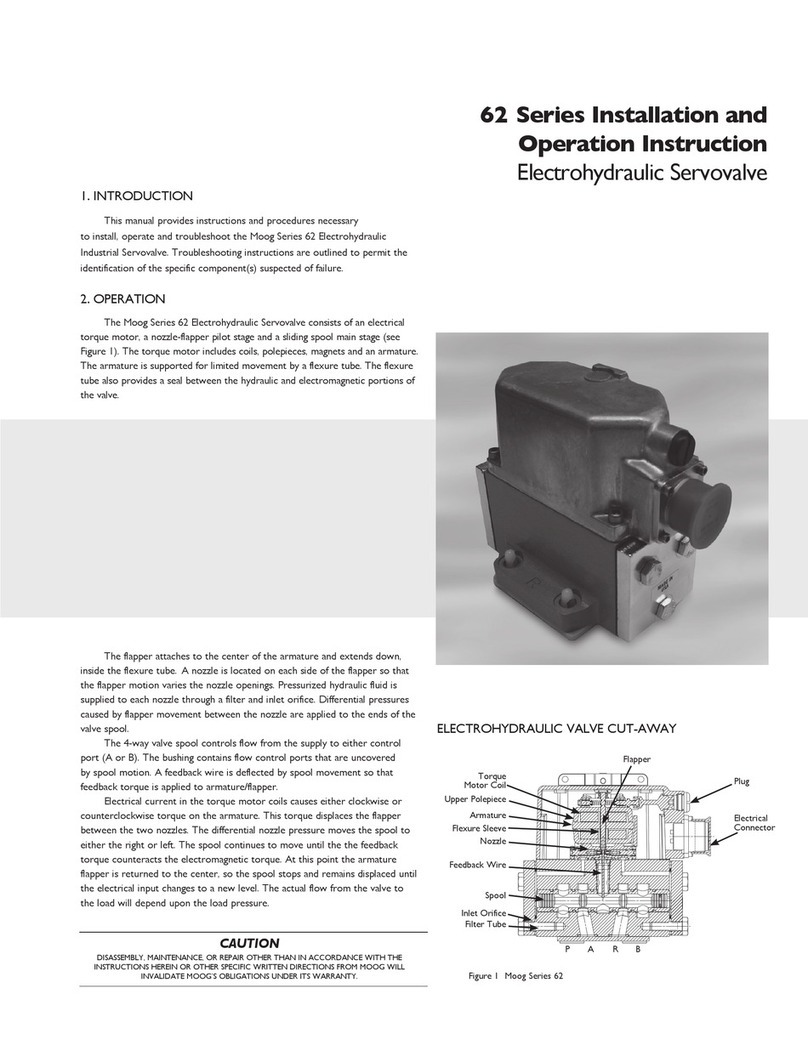

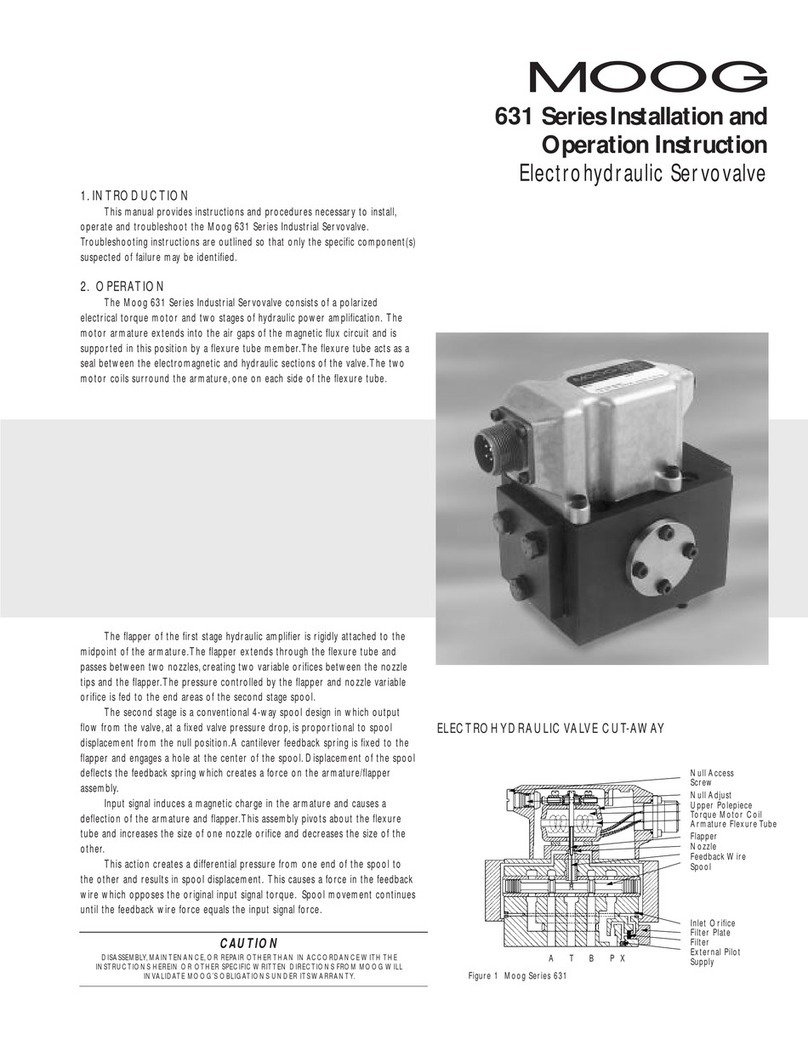

7. MECHANICAL NULL ADJUSTMENT

It is often desirable to adjust the flow null of a servovalve independent

of other system parameters. The “mechanical null adjustment” on the Moog

.760K Series servovalve allows at least ±20% adjustment of flow null.

The “mechanical null adjustor” is an eccentric bushing retainer pin, located

above the “tank” port designation on the valve body (see Figure 2) which, when

rotated, provides control of the bushing position. Mechanical feedback elements

position the spool relative to the valve body for a given input signal. Therefore, a

movement of the bushing relative to the body changes the flow null.

Adjustment Procedure

Using a 3/8inch offset box wrench, loosen the self-locking fitting until the

null adjustor pin can be rotated. (This should usually be less than 1/2 turn).

DO NOT remove self-locking fitting. Insert a 3/32 inch Allen wrench in null

adjustor pin. Use the 3/32 Allen wrench to rotate the mechanical null adjustor

pin to obtain desired flow null. Torque self-locking fitting to 57 inch lbs.

Note: Clockwise rotation of null adjustor pin produces flow from port P to port B.

3. ELECTRICAL INFORMATION AND INTRINSICALLY SAFE

CIRCUIT SAFETY PARAMETERS

a. A wide choice of coils is available for a variety of rated current

requirements. The torque motor coil leads are attached to the connector

so external connections can provide series, parallel or single coil operation.

The valves are equipped either with an MS type connector or with pigtail

leads for electrical wiring. Refer to installation drawings of the specific

model for details. Servovalve coils should be driven with current to

provide consistency throughout the temperature range.

b. The .760K valves are approved for intrinsically safe protection per EN IEC

60079-0 : 2018, EN 60079-7 : 2015, and EN 60079-11 : 2012 for ATEX, and

IEC 60079-0 : 2017, IEC 60079-7 : 2017, and IEC 60079-11 : 2011 for IECEx.

The approved safety parameters are listed in the following table for all the

coils used by .760K series. Coil number is marked on the valve nameplate.

Coil Configuration Marking Ui(MAX) Ii(MAX)

G4220-031 (single, series, parallel) Ex ia IIB T4 12 V 120 mA

G4220-051/098 (single, series, parallel) Ex ia IIB T4 12 V 240 mA

G4221-001 G4220-042 (single) Ex ia IIC T4 16 V 160 mA

G4221-001 G4220-042 (single) Ex ia IIC T4 24.4 V 85 mA

G4220-031 (single, parallel) Ex ia IIC T4 30 V 26 mA

G4220-031 (series) Ex ia IIC T4 30 V 18 mA

G4220-051/098 (single, parallel) Ex ia IIC T4 30 V 19 mA

G4220-051/098 (series) Ex ia IIC T4 30 V 12.7 mA

G4220-042 (single) Ex ia IIC T4 30 V 37 mA

G4220-042 (parallel) Ex ia IIC T4 30 V 20 mA

G4220-042 (series) Ex ia IIC T4 30 V 10 mA

G4221-001 (single) Ex ia IIC T4 30 V 28 mA

c. The .760K valves are approved for non-incendive operation for supply

current not to exceed 50 mA dc.

d. When making electric connections to the valve, appropriate measures

must be taken to ensure that locally different earth potential do not

result in excessive ground currents. When barriers are required for

the hazardous location, hazardous area (field) wiring must meet the

requirements of the barrier manufacturer. All barriers must be mounted

and installed in compliance with the barrier manufacturer’s requirements.

Twisted pairs of 18-20 gage wire are recommended. If shielded wire is

used, connect shield wire to earth ground only at the barrier strip.

4. SPECIAL CONDITIONS FOR SAFE USE

Because the enclosure of the apparatus is made of aluminum, if it is

mounted in an area where the use of category 1 G apparatus is required, it

must be installed such that even in the event of rare incidents, ignition sources

due to impact and friction sparks are excluded.

When the electrohydraulic servovalve is used in an application for type of

explosion protection intrinsic safety “i”, the appropriate box on the data label

must be scored. When the electrohydraulic servovalve is used in an application

for type of explosion protection “n”, the appropriate box on the data label

must be scored.

After use in an application for type of explosion protection “n”, the

servovalve cannot abe safely used in a intrinsically safe application.

The screwed cable connector may only be disconnected when the circuit

is de-energized or when the location is known to be non-hazardous.

When used at an ambient temperature ≥70°C, heat resistant cable must

be used with a continuous operating temperature in accordance with the

application.

When the electrohydraulic servovalve is used in type of protection “n”

or “ec”, the equipment shall only be used in an area of not more than Pollution

Degree 2, as defined in IEC 60664-1.

The cable gland shall be installed such that impact is not possible.

When the electrohydraulic servovalve is used in type of protection “n”

or “ec”, the user shall provide additional clamping of the cable to ensure that

pulling is not transmitted to the terminations.

Figure 2

Mechanical Null Adjustment