Potential Trouble

Servovalve does not follow input command

signal. (Actuator or components are

stationary or creeping slowly.)

Poor response. (Servovalve output lags

electrical command signal).

Output flow obtained from one control

port only. (Actuator is hardover, or

hydraulic motor is rapidly rotating. No

response to electrical command signal.)

Low flow gain. (Failure to meet high rate or

rapid traverse speeds.)

High threshold. (Jerky, possible oscillatory

or “hunting” motion in closed loop system.)

High Null Bias. (High input current required

to maintain hydraulic cylinder or motor

stationary.)

Probable Cause

1. Open coil assembly or open coil leads.

2. Plugged inlet filter element.

Partially plugged filter element.

1. Plugged inlet orifices.

2. Plugged inlet filter element.

3. Plugged hydraulic amplifier assembly.

4. Jammed spool.

Shorted coil assembly.

“Sticky” spool

1. Incorrect null adjustment

2. Partially plugged inlet orifice assembly.

3. Partially plugged filter element.

4. Partially plugged nozzle.

Remedy

1. Return to factory.

2. Replace filter element.

Replace filter element and check for dirty

hydraulic fluid in system.

1. Return to factory.

2. Replace filter element.

3. Return to factory.

4. Return to factory.

Return to factory.

Clean bushing and spool assembly.

1. Readjust null

2. Return to factory.

3. Replace filter element and check for dirty

hydraulic fluid in system.

4. Return to factory.

8.TROUBLESHOOTING CHART

The following troubleshooting chart list potential troubles encountered, probable causes, and remedies.

9. FIELD REPLACEABLE FILTER ASSEMBLY REPLACEMENT

a. Remove four socket head cap screws and lockwashers on filter cover

using a 5/32 inch Allen wrench. Remove filter cover plate. Use 1/4 inch-28

screw to pull filter plug out.

b. Remove O-Rings from filter plug and filter.

c. Inspect filter for foreign material and discard.

d. Install O-Rings on filter plug and inside filter.

e. Install filter, filter plug and cover plate.Torque screw to 85 inch-pounds.

10. PILOT STAGE FILTER REPLACEMENT

a. Remove torque motor cover leaving all electrical connections in place.

b. Locate Pilot Stage Filter in Nozzle Block of torque motor assembly.

Remove screws, lockwashers and cover plates from both sides.

c. Remove filter plugs from both sides of nozzle block and one (1) inlet orifice

assembly using a 2-56 screw which threads into the filter plug and inlet

orifice assembly. Use the 2-56 screw in the remaining inlet orifice assembly

to help remove filter tube. Note:These inlet orifice assemblies seat in

nozzle block and cannot go through bore during removal.

d. Remove O-rings from filter plugs and O-rings from inlet orifice assemblies.

e. Visually inspect filter orifice assemblies for damage or foreign matter.

f. Discard old O-rings and old filter tube.

g. Install new O-rings on filter plugs, and new O-rings on inlet orifices.

h. Install new filter tube back into torque motor nozzle block with one (1)

inlet orifice assembly inserted into filter tube. Follow with filter plug. Install

the other inlet orifice assembly and filter plug into the other end of filter

tube. Note: Inlet orifice assemblies and filter plugs are interchangeable.

i. Reinstall both cover plates with screws and lockwashers.Torque to 10+/-1

inch-pounds.

11. FUNCTIONAL CHECKOUT AND CENTERING

a. Install servovalve on hydraulic system or test fixture, but do not connect

electrical lead.

b. Apply required system pressure to servovalve and visually examine for

evidence of external leakage. If leakage is present and cannot be rectified

by replacing O-Rings, remove the discrepant component and return for

repair or replacement.

Note: If the system components are drifting or hardover, adjust

the mechanical null of the servovalve.

c. Connect electrical lead to servovalve and check phasing in accordance

with system requirements.

12.AUTHORIZED REPAIR FACILITIES

Moog does not authorize any facilities other than Moog or Moog

subsidiaries to repair its servovalves. It is recommended you contact Moog at

(716) 652-2000 or visit www.moog.com/worldwide to locate your closest Moog

repair facility. Repair by an independent (unauthorized) repair house will result

in voiding the Moog warranty and could lead to performance degradation or

safety problems.

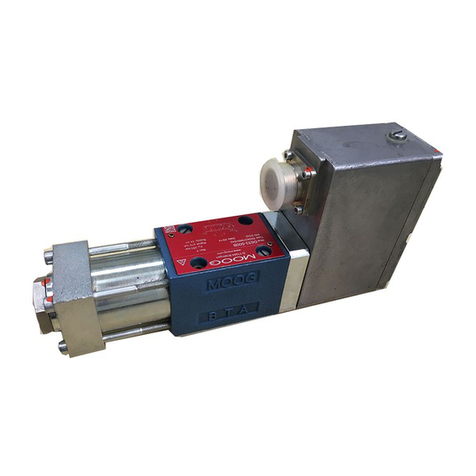

Figure 4

Filter Tube

Inlet Orifice

Assembly

Filter Plug

Field

Replaceable

Filter

Filter Housing

O-Rings

Table 1. Replacement Parts

Part Description Qty. Part Number

72 Series Filter Replacement Kit 1 B52555RK099K001

Base O-Rings 4 -42082-040

Filter Housing O-Rings (I) 2 -42082-039

External Pilot Supply and Field

Replaceable Filter Internal O-Ring (I) 1 -42082-013

Filter Plug O-Rings (I) 2 -42082-060

Inlet Orifice O-Rings (I) 2 -42082-059

Pilot Stage Filter Tube (I) 1 -23020

Field Replaceable Filter (I) 1 -22050

Motor Cap Gasket (1) 1 -24509

(I) Included in Filter Replacement Kit.

Moog • 72 Series Operation Instruction • RevE 04/07 3

Pilot Stage Filter

(in Nozzle Block)

Torque Motor

Assembly

(cover not shown)