DDA

Page 1

The Interface Solution Experts

Introduction

Moore Industries’ DIN-style Direct Current alarm, the

DDA, accepts all standard process current and volt-

age inputs and provides an alarm response to input

that falls outside of an adjustable preset limit. The

DDA comes in single- and dual- alarm models. The

dual-alarm model allows two separate trip points to

be configured per module.

This manual contains the information necessary to

calibrate, install, operate, maintain, and troubleshoot

the DDA. It includes a brief unit description, a table

of performance and operational specifications, and

an explanation of Moore Industries’ model number

based product data tracking system.

The following guidelines are used throughout the

manual:

WARNING

– Hazardous procedure or condition that

could injure the operator.

Caution

– Hazardous procedure or condition that

could damage or destroy the unit.

Note

– Information that is helpful for a procedure,

condition, or operation of the unit.

Description

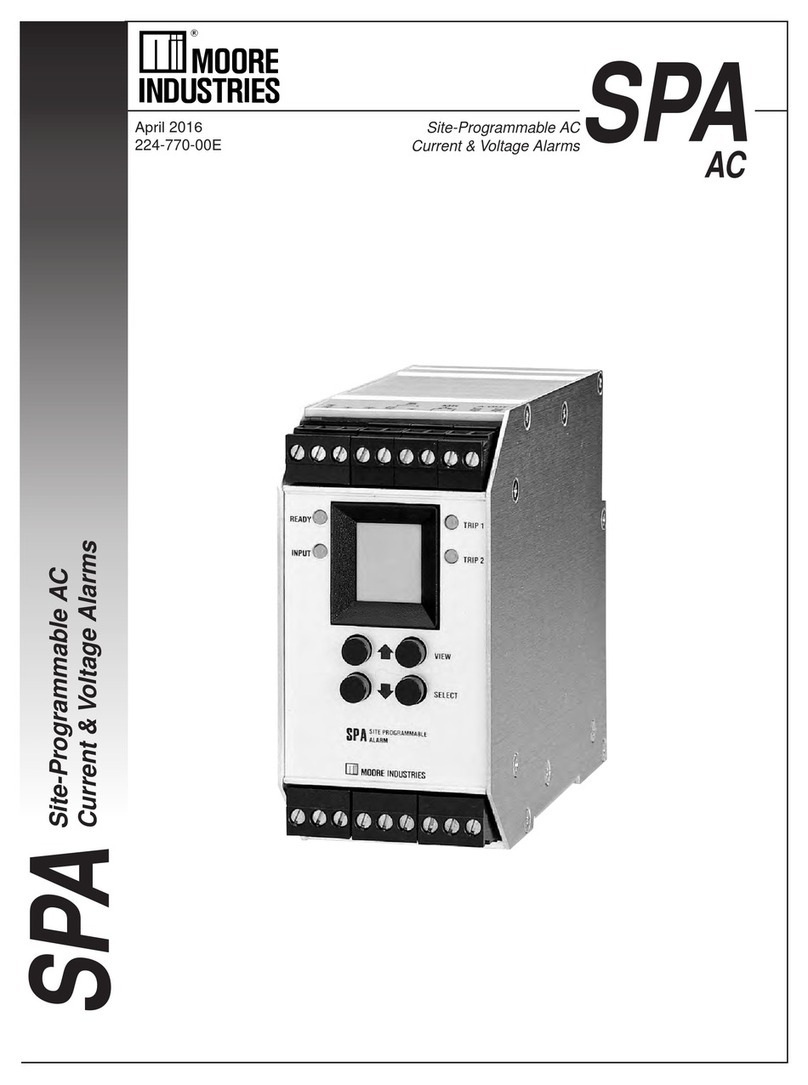

The DDA is a 4-wire, process alarm that is powered

by an external 24 Vdc power source. It accepts stan-

dard process current or voltage (factory-set) and re-

sponds to a user-adjustable trip point by changing

the output state when the input exceeds the trip point

setting. The output is either a normally-open (NO) or

normally-closed (NC) relay contact-closure (stan-

dard), or an opto-isolated, open-collector transistor

(optional).

The DDA is factory-set for single- or dual-alarm

operation. Standard single-alarm units have a

double-pole, double-throw (DPDT) relay output (out-

put A). Standard dual-alarm units have two single-

pole, double-throw (SPDT) relay outputs (outputs A

and B).

The standard DDA has a built-in 1.0 percent dead

band. The unit resets when the input signal has

crossed over the trip point on its return to the user-

selected non-alarm range, and is 1.0 percent of span

beyond the trip point.

The unit housing is a plastic, DIN-style case that can

be mounted on either a DIN-style top-hat rail (stan-

dard) or G-rail (optional). Refer to the Installation

Section for housing dimensions.

Specifications

Display Accuracy:

±0.1% of input span;

±1 count to include

repeatability,

hysteresis, and

adjustment

resolution

Repeatability: Trip

point repeats within

±0.1% of input span

Dead Band: 1% of

input span (stan-

dard)

Signal Response:

-3dB @ 5Hz typical

(low pass)

Alarm Response:

50 milliseconds

standard

Isolation: 500Vac,

input to output to

power

RFI/EMI Effect: With field

strengths of 10V/m, at

frequencies of 20-500 Mhz,

unit will not go into alarm

status unless process

variable is within ±1.0% of

trip point

Range: -18°C to 65°C

(0°F to 149°F)

Effect: ±0.018% of span/°C

Front Panel Adjustments

Type: Multiturn

potentiometers

Trip Point(s): Adjust over a

range of -5% to 105% of

span, typical

Input/Trip Point Viewing:

Two or three-position rotary

switch allows selection of

viewing the Input, Trip A, or

Trip B on the integral LCD

Internal Adjustments Type:

Multiturn potentiometers

Zero: Adjustable to ±10% of

span

Span: With full scale input,

output is adjustable to 100%,

±10% of span.

Display: 3½ digit LCD

displays either Input, Trip A

setting, or Trip B setting as

determined by rotary switch;

display indicates from -5.0%

to 105% of input span and id

linear with respect to the

input signal

Trip Point: Led(s) on front

panel indicates alarm status

for each trip point ("ON" LED

indicates energized relay)

297 grams (10.5 ounces)

Peformance Peformance

(continued)

Ambient

Temperature

Adjustments

Adjustments

(continued)

Indicators

Weight